Shell for condensing equipment

A technology for condensing equipment and casings, which is applied in the field of casings for condensing equipment, and can solve problems such as heat dissipation obstruction of condenser casings, condenser damage, troublesome operation, etc., so as to reduce the time for disassembling and assembling casings, improve efficiency, and facilitate maintenance and maintenance work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

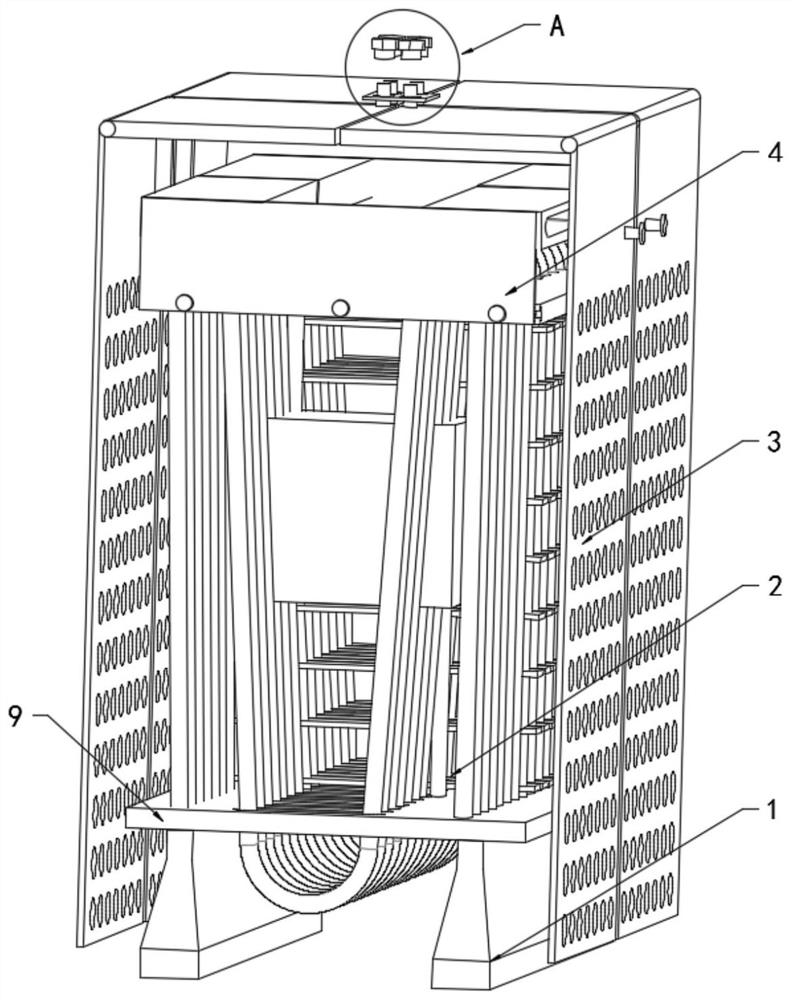

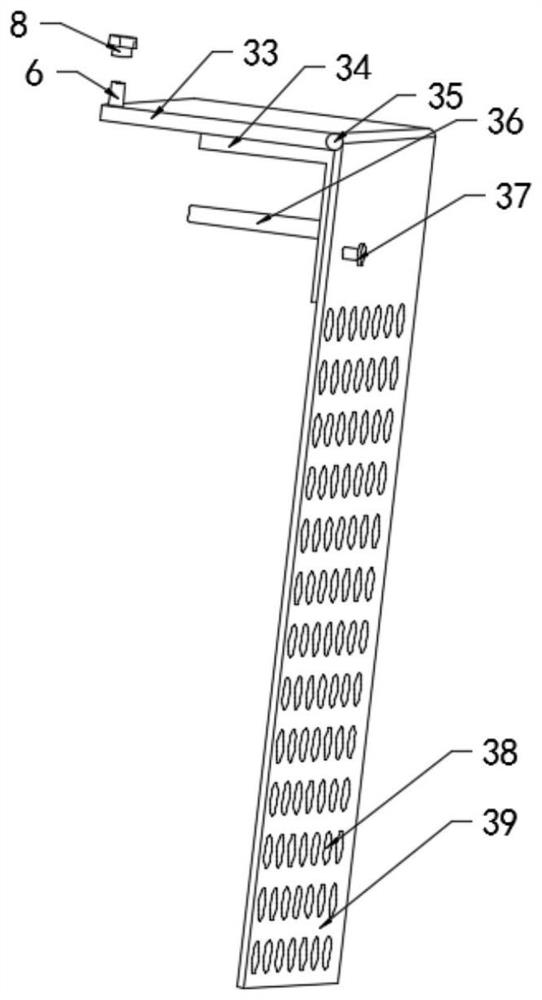

[0036] refer to Figure 1-4 , a shell for condensing equipment, including a condenser 2, a bottom plate 9 connected to the bottom of the condenser 2, support legs 1 connected to both sides of the bottom of the bottom plate 9, and both sides of the condenser 2 are connected with a protective mechanism 3 through a connecting mechanism 4, The protective mechanism 3 includes multiple sets of protective shells 39, one side of the protective shell 39 is provided with a top plate 33, and the top side of each top plate 33 is provided with a first screw 6, and the top plate 33 is rotationally connected with the protective shell 39 through a rotating shaft 35. The corresponding inboard of top plate 33 and protective shell 39 is provided with connecting rod 34, and the side view surface of connecting rod 34 is L-shaped, and one side of the vertical section of connecting rod 34 is connected with protective shell 39 bolts by second screw rod 37, connects The top of the horizontal section o...

no. 2 example

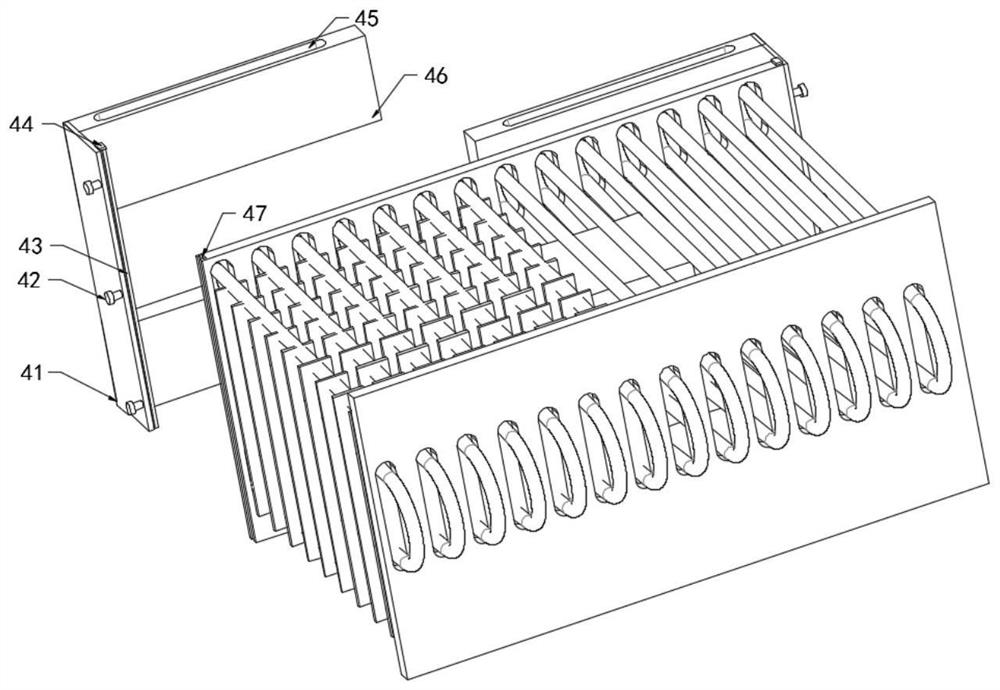

[0044] Based on the casing for condensing equipment provided in the first embodiment, the quick disassembly and assembly of the casing of the condensing equipment is realized, and the maintenance and replacement are convenient. However, in actual use, the casing is in close contact with the condenser 2, and the temperature of the casing will still rise accordingly. High, its own service durability will be greatly reduced, and workers can still cause damage to it when they accidentally touch the shell, and it is obviously not enough to achieve rapid heat dissipation only by ventilation holes 38 and natural wind. The efficiency is poor, let alone the specific heat dissipation treatment for specific parts, the adaptability is poor, and the fixed-point heat dissipation capability is poor. Figure 5-9 , this kind of condensing equipment shell also includes: the interior of the top plate 33 is provided with a heat dissipation fan 11, through the heat dissipation fan 11, the condenser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com