Low-temperature pipe body storage device

A storage device and low-temperature technology, which is applied in the field of freezing and cooling, can solve the problems of difficult consistency of test tube freezing rate, easy slipping of samples, poor temperature consistency, etc., and achieve the goal of improving the consistency of freezing rate, temperature consistency and working time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

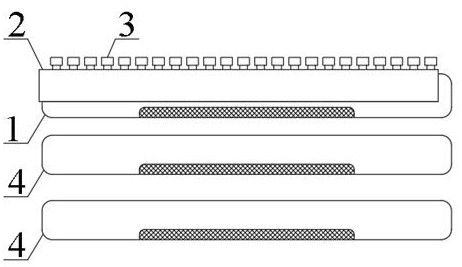

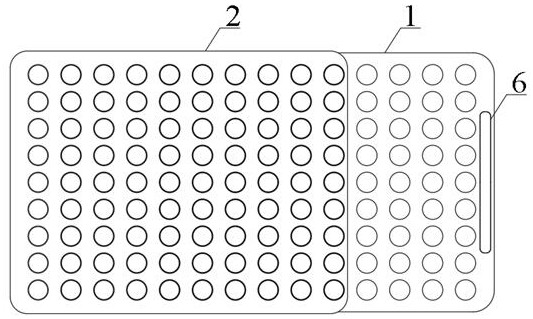

[0051] Such as Figure 1 to Figure 9 As shown, a low-temperature storage device with a tube body includes a heat-conducting metal block 1 and a sliding cover 2. In the figure, the heat-conducting metal block 1 is a metal shell structure, and the inside of the heat-conducting metal block 1 is sealed and filled with phase change materials. Generally, The heat-conducting metal block 1 is stored at -20°C. The slide cover 2 is slidably installed on the heat-conducting metal block 1. The distance between the lower surface of the slide cover 2 and the upper surface of the heat-conducting metal block 1 is 0.3cm to 1.5cm. The heat-conducting metal block 1 It is made of metal materials with good thermal conductivity such as aluminum alloy and copper, and the sliding cover 2 can be made of metal materials or non-metal materials.

[0052] Specifically, a plurality of working holes 101 for installing pipe fittings 3 are uniformly opened on the heat-conducting metal block 1. The pipe fittin...

Embodiment 2

[0056] Such as Figure 10 to Figure 13 , in order to prolong the low-temperature time of the heat-conducting metal block 1, the heat-conducting metal block 1 can be directly placed on the cold source, therefore, the metal cold block 4 is designed. The metal cold block 4 is a metal shell structure, and the inside of the heat-conducting metal block 1 is sealed and filled with phase change materials. The outer contour size of the metal cold block 4 is consistent with the outer contour size of the heat-conducting metal block 1. There is a side groove for installing the protection pad 401, and the thickness of the protection pad 401 is consistent with the depth of the side groove to ensure the smoothness of the surface of the metal cold block 4, and the two metal cold blocks 4 can fit closely and transfer heat. In this embodiment, the top of the heat-conducting metal block 1 can be provided with a concave platform for accommodating the protective pad 401 of the upper heat-conductin...

Embodiment 3

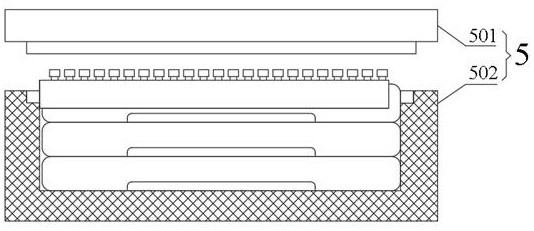

[0060] In this instance, figure 2 A heat-insulating box 5 is designed, which is composed of a box body 501 and a cover body 502. The heat-insulating box 5 is used to place the heat-conducting metal block 1, the sliding cover 2, the pipe fitting 3 and the metal cold block 4. Especially when long-distance transportation or storage is required, the use of the heat insulation box 5 can effectively reduce heat exchange and increase the low-temperature time. The heat insulation box 5 can be made of heat-insulating materials, such as high-density foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com