Self-propelled rice seedling raising tray placing machine

A self-propelled technology for raising rice seedlings, applied in transplanting machinery, planting methods, applications, etc., can solve the problems of high labor intensity and lifting of seedling raising, and achieve the effect of reducing labor intensity and prolonging pressing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

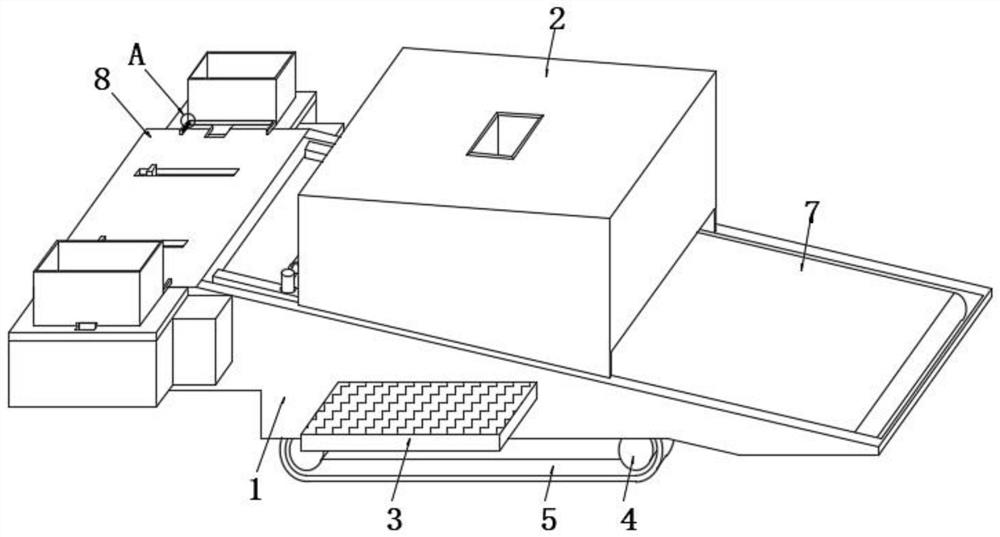

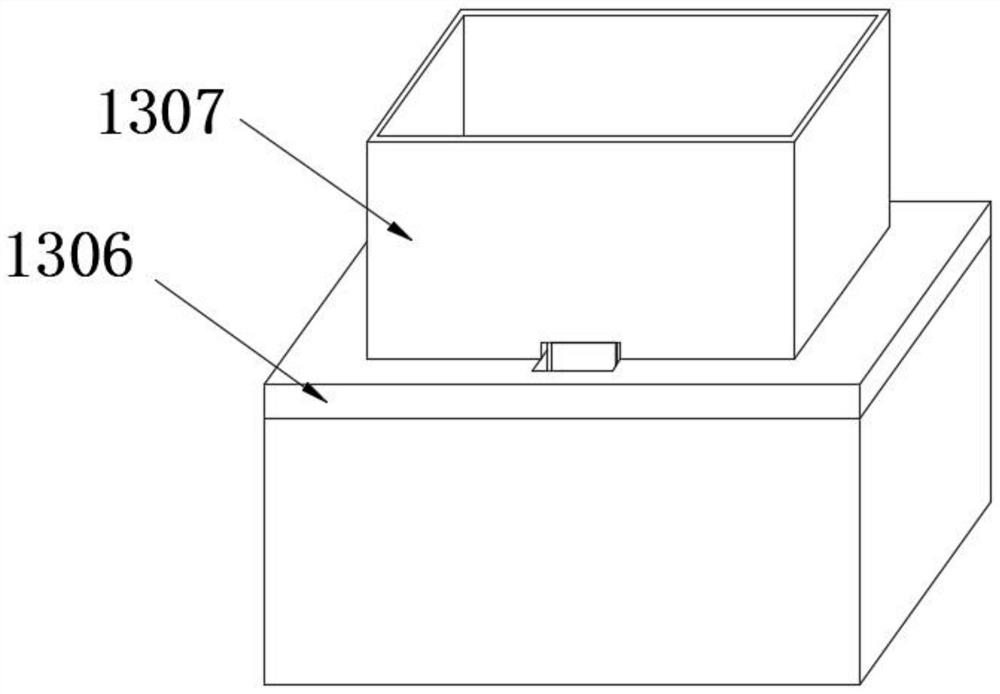

[0036] see Figure 1-7 As shown, the present invention is a kind of self-propelled rice seedling raising machine, comprising a support frame 1, an anti-warping assembly 11 and a feeding mechanism 13, the upper surface of the support frame 1 is fixedly connected with a filling frame 2, and the support frame 1 The drive pulley 6 is connected to the inside for rotation, and the conveyor belt 7 is sleeved on the outside of the drive pulley 6. The whole seedling tray is placed inside the seedling tray box 1307, and the side of the support frame 1 away from the conveyor belt 7 is fixedly connected to the workbench. 8. The side of the feeding mechanism 13 away from the drive screw 12 is fixedly connected to the drive screw 2 14, the drive screw 12 and the drive screw 2 14 are connected through the coaxial rod 1301, and the other end of the drive screw 14 rotates with the inner wall of the workbench 8 Connect, the inside of workbench 8 is provided with feeding mechanism 9, and one sid...

Embodiment 2

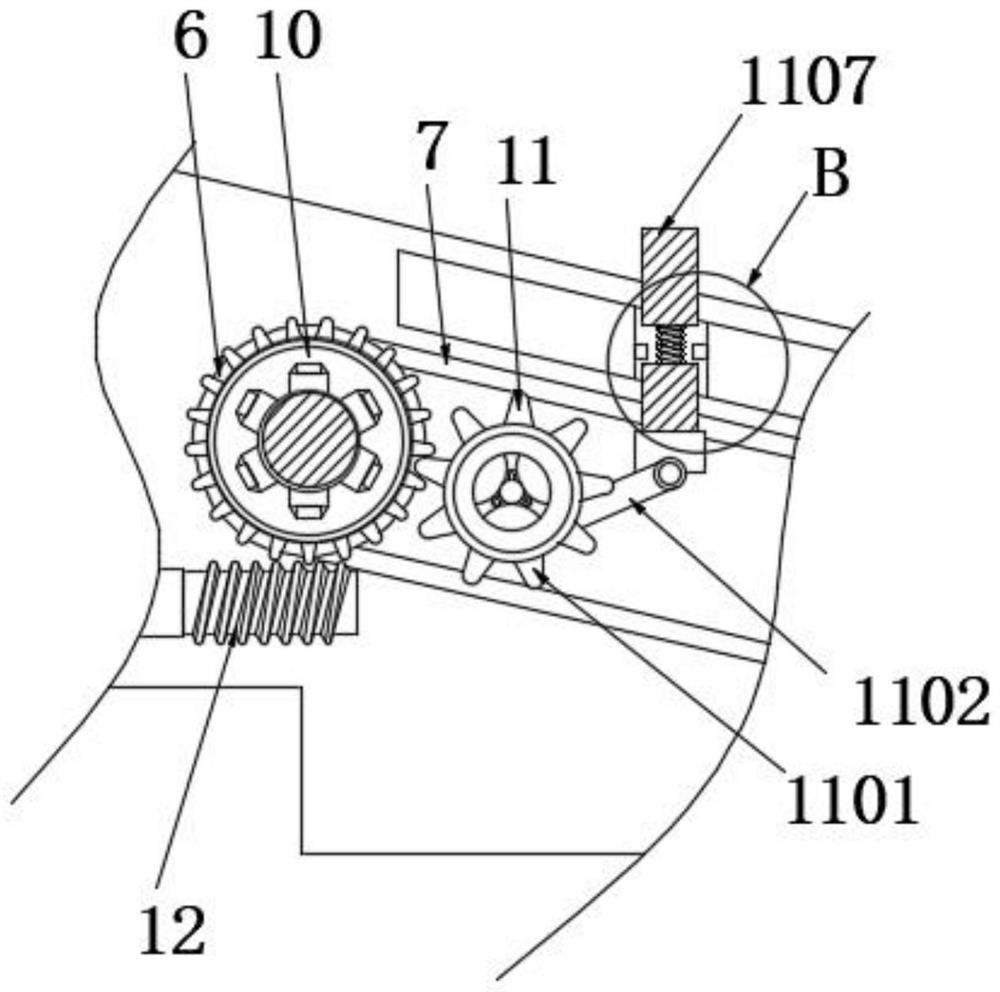

[0041] Such as Figure 8-9 As shown, the anti-warping assembly 11 includes an intermittent wheel 1101. Through the transmission between the gears, the transmission gear 10 drives the intermittent wheel 1101 to rotate, and the intermittent wheel 1101 drives the linkage rod 1102 to move through the shaft, and the linkage rod 1102 is far away from the intermittent wheel 1101. One end of the fixed block 1103 is fixedly connected, and the side of the fixed block 1103 away from the linkage rod 1102 is fixedly connected to the pull rod 1104. The upper end of the pull rod 1104 is externally sleeved with an auxiliary guide plate 1106. When the linkage rod 1102 pulls the fixed block 1103 downward, the seedling tray moves to the surface of the conveyor belt 7, the fixed block 1103 drives the pull rod 1104 to move down inside the auxiliary guide plate 1106, one side of the auxiliary guide plate 1106 is fixedly connected with the inner wall of the support frame 1, and the seedling tray is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com