A rescue expansion device and method based on shape memory alloy

A memory alloy and expansion device technology, used in life-saving equipment, building rescue and other directions, can solve the problems of flying debris safety hazards, damage to the surrounding environment, waste of rescue time and other problems, achieve low professional level requirements, improve rescue safety, The effect of reducing rescue costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

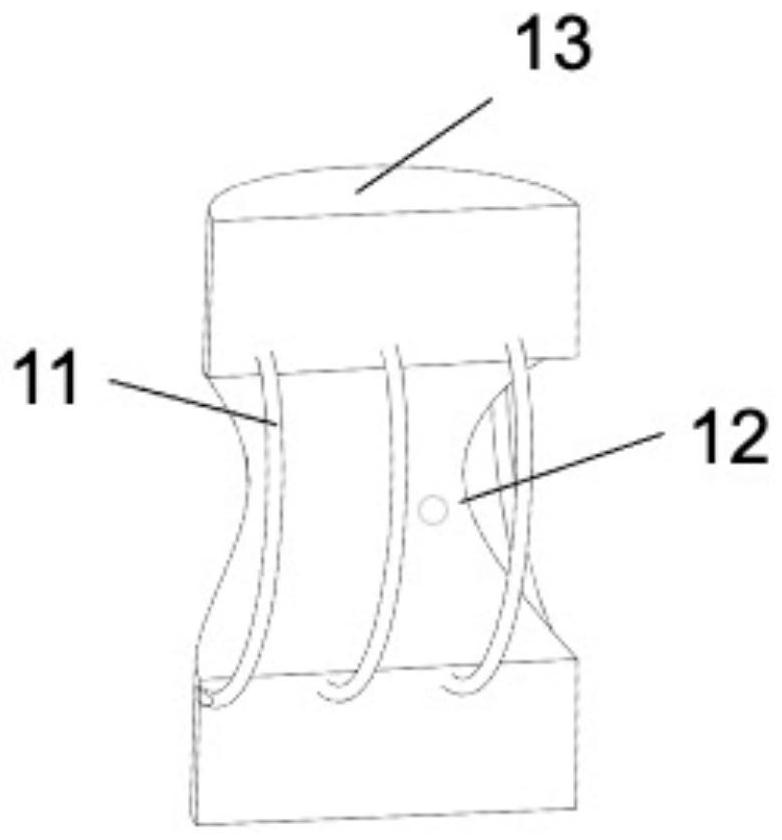

[0061] The preparation process of the auxiliary chuck alloy is as follows: In this technical solution, after the raw materials are cast into ingots by vacuum induction melting, the ingots are homogenized at 900-1200° C. for 12-36 hours. Subsequently, the homogenized alloy is thermally deformed (rod, plate, etc.) to obtain a thermal deformation of 20%-70%, and then the alloy is subjected to long-term aging treatment at 400-600°C for 20-120min at different times, and is cut by EDM Processed as wedge, cone, cylinder, claw, hemispherical and truncated cone. Different types of auxiliary chucks can be loaded into the reserved chuck loading area. The wedge-shaped chucks are divided into two types: front opening type and rear opening type, and the whole is made of shape memory alloy. The front-opening expansion element has a wedge-shaped opening at the front end and a cuboid-shaped tail end, which is convenient for direct loading with the sleeve or other heaters. Before heating, the ...

Embodiment 1

[0065] The operation steps of the shape memory alloy rescue expansion device of the present invention will be described in detail below.

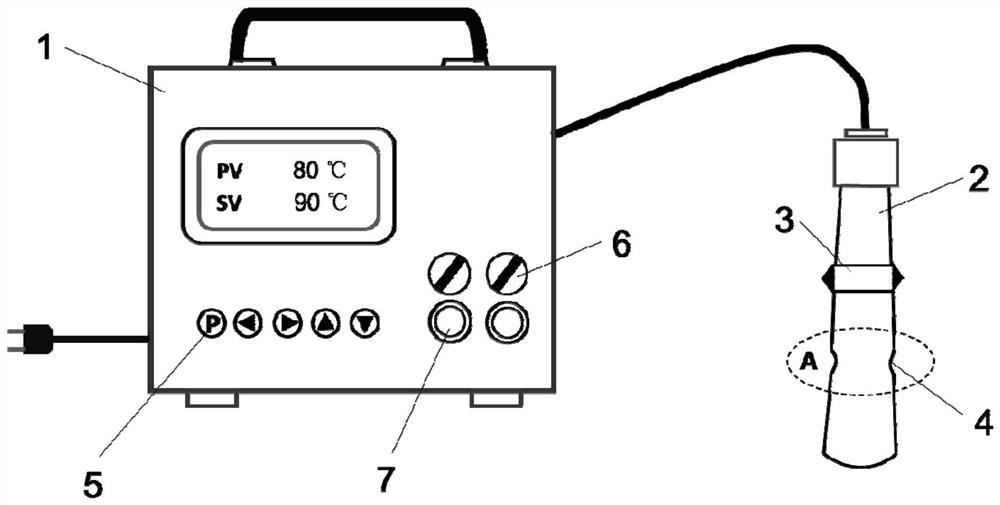

[0066] see figure 1 , Figure 3(a), (b), Figure 4(a), (b).

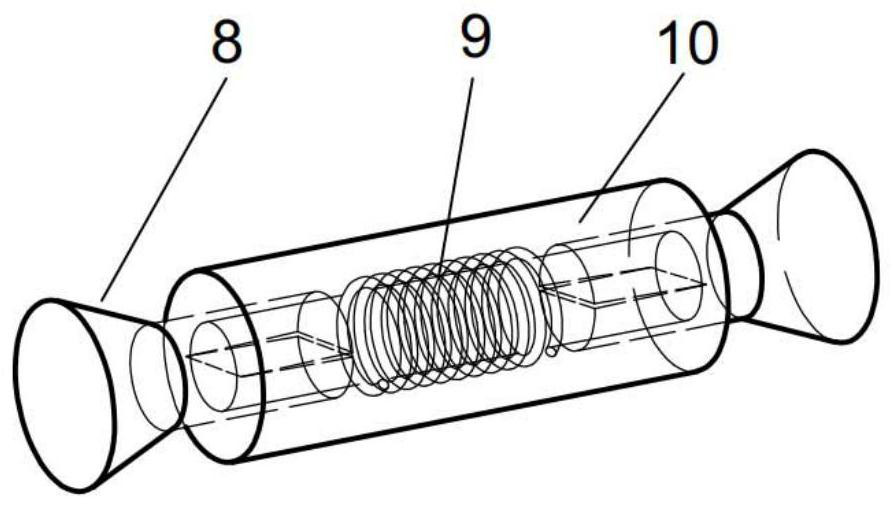

[0067] Such as figure 1 Shown is the overall device situation before the present invention is not opened. To reach a specific rescue environment requiring support, select an appropriate alloy expansion element 3 according to the environmental conditions. As shown in Figure 3(a) and (b), the cross-sectional view of the rear-opening wedge-shaped alloy expansion element (before heating), the rear-opening wedge-shaped auxiliary chuck 8 that can be used for support is selected in the rescue environment, which is composed of Ti 49.9 Ni 50.1 The shape memory alloy is prepared, and its wedge angle is 30° before heating.

[0068] Fix the shape memory alloy spring 9 on the metal tube 10, and load the rear-opening wedge-shaped auxiliary chuck 8 on both sides of the metal tube 10. In this...

Embodiment 2

[0074] see figure 1 , Figure 8(a), (b), such as figure 1 Shown is the overall device situation before the present invention is not opened.

[0075] To reach a specific rescue environment that needs to be expanded, select an appropriate alloy expansion element 3 according to the environmental conditions. As shown in Figure 8(a), it is a front sectional view of the heated pincer-shaped expansion element (front opening type) of the present invention, and the front-opening pincer-shaped auxiliary chuck 8 that can be used for expansion and rescue is selected in the rescue environment where expansion is required. , which consists of Ti 50.0 Ni 50.0 The shape memory alloy is prepared, and the included angle of the pincers is 30° before heating.

[0076] Fix the shape memory alloy spring 9 to the metal tube 10, and load the front-opening pincer-shaped auxiliary chuck 8 on both sides of the metal tube 10. In this example, Ti 50.0 Ni 50.0 The shape memory alloy spring 9 has a spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com