Liquid-liquid phase change absorbent with controllable carbon dioxide capture threshold

A carbon dioxide and absorbent technology, applied in chemical instruments and methods, separation of dispersed particles, air quality improvement, etc., can solve the problem of high energy consumption for desorption, achieve rapid phase separation, wide application prospects, and good regeneration stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

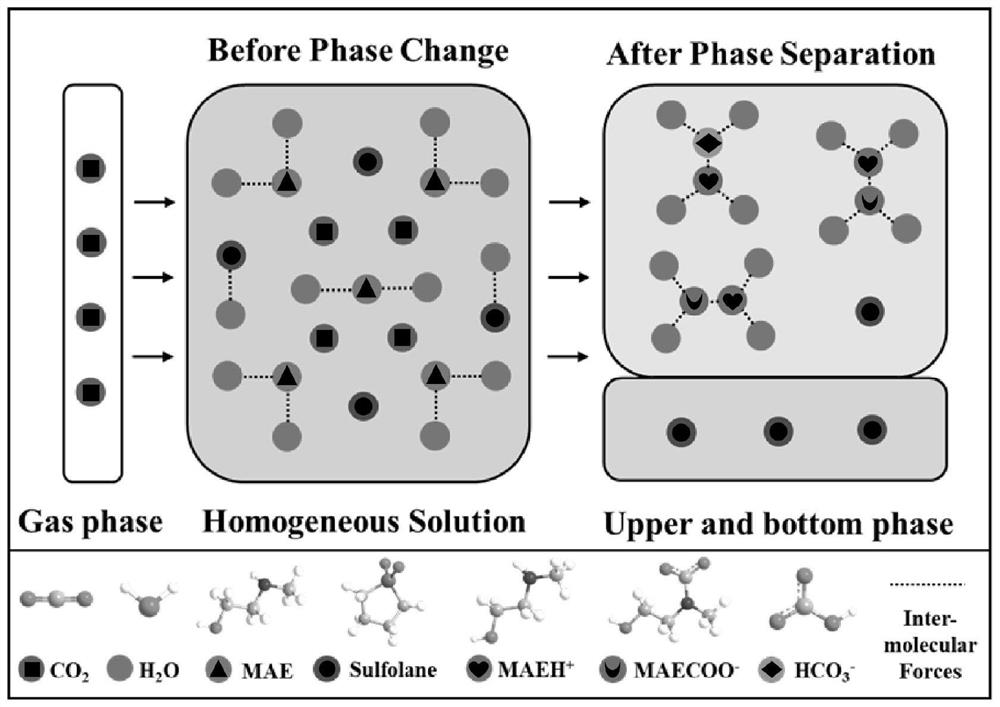

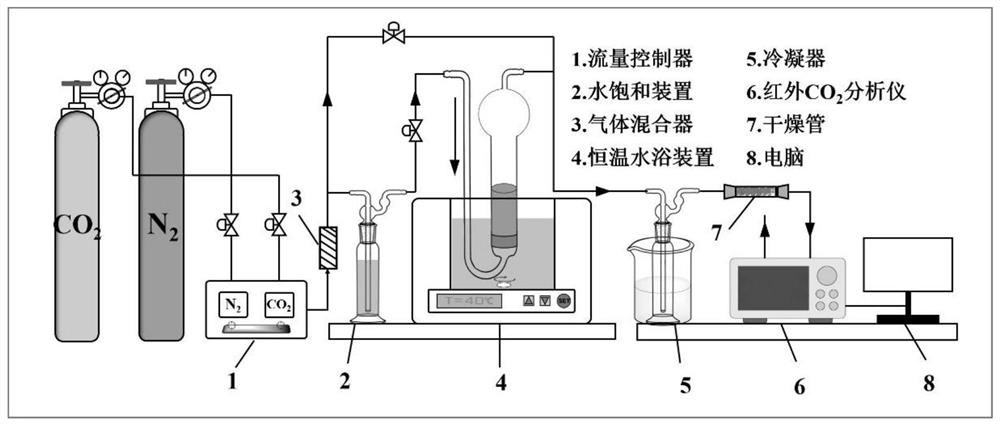

Method used

Image

Examples

Embodiment 1

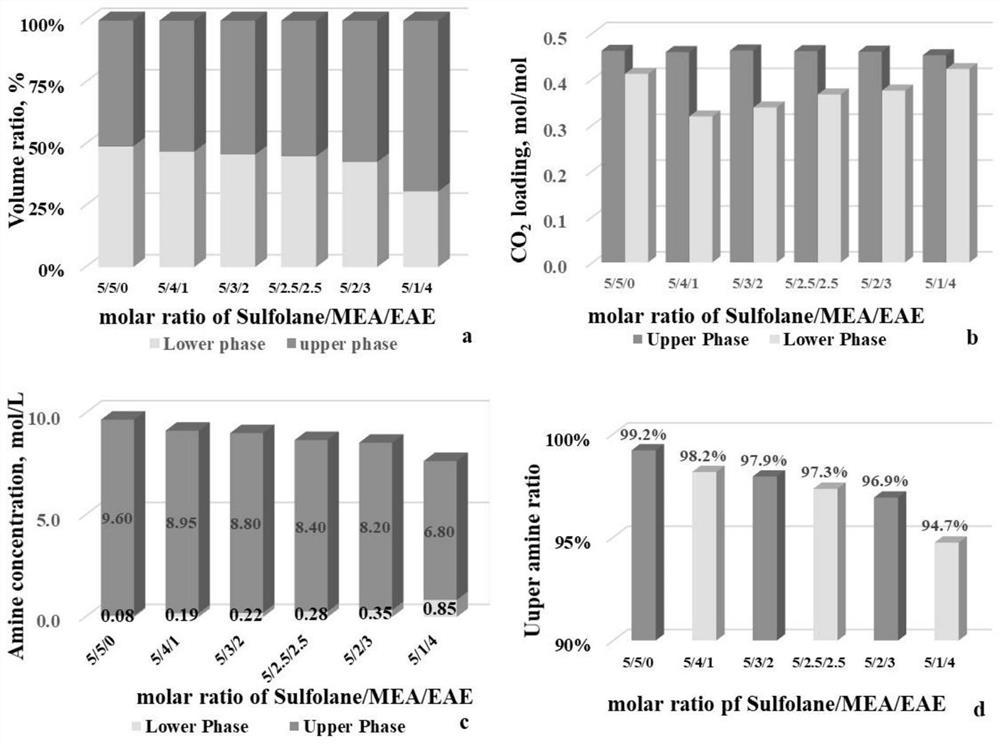

[0025] A liquid-liquid phase change absorbent for carbon dioxide capture, consisting of main absorbents MEA and EAE, phase separation accelerator sulfolane and solvent water, wherein the concentration of MEA is 4mol / L, and the concentration of EAE is 1mol / L, The concentration of sulfolane is 5mol / L.

[0026] The absorbent is used to absorb CO 2 For simulated flue gas with a volume fraction of 15%, the absorption temperature is 40°C and the absorption time is 30 minutes. Absorbent absorbs CO 2 When saturation is reached, the absorbent separates into two phases and the CO 2 The rich phase is separated and sent to desorption regeneration, the regeneration temperature is 120°C, and the regeneration time is 150min.

Embodiment 2

[0028] A liquid-liquid phase-change absorbent for carbon dioxide capture, consisting of main absorbents MEA and EAE, phase-separation accelerator sulfolane and solvent water, wherein the concentration of MEA is 3mol / L, and the concentration of EAE is 2mol / L, The concentration of sulfolane is 5mol / L. All the other are identical with embodiment 1.

Embodiment 3

[0030] A liquid-liquid phase change absorbent for carbon dioxide capture, consisting of main absorbents MEA and EAE, phase separation accelerator sulfolane and solvent water, wherein the concentration of MEA is 2.5mol / L, and the concentration of EAE is 2.5mol / L L, the concentration of sulfolane is 5mol / L. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com