Woven bag interior cleaning device

A cleaning device and woven bag technology, which are applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of affecting the quality of finished products, removing difficult powders and flocs, and low efficiency. Achieve the effects of improving production and recycling efficiency, reducing the risk of hooking and scratching, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

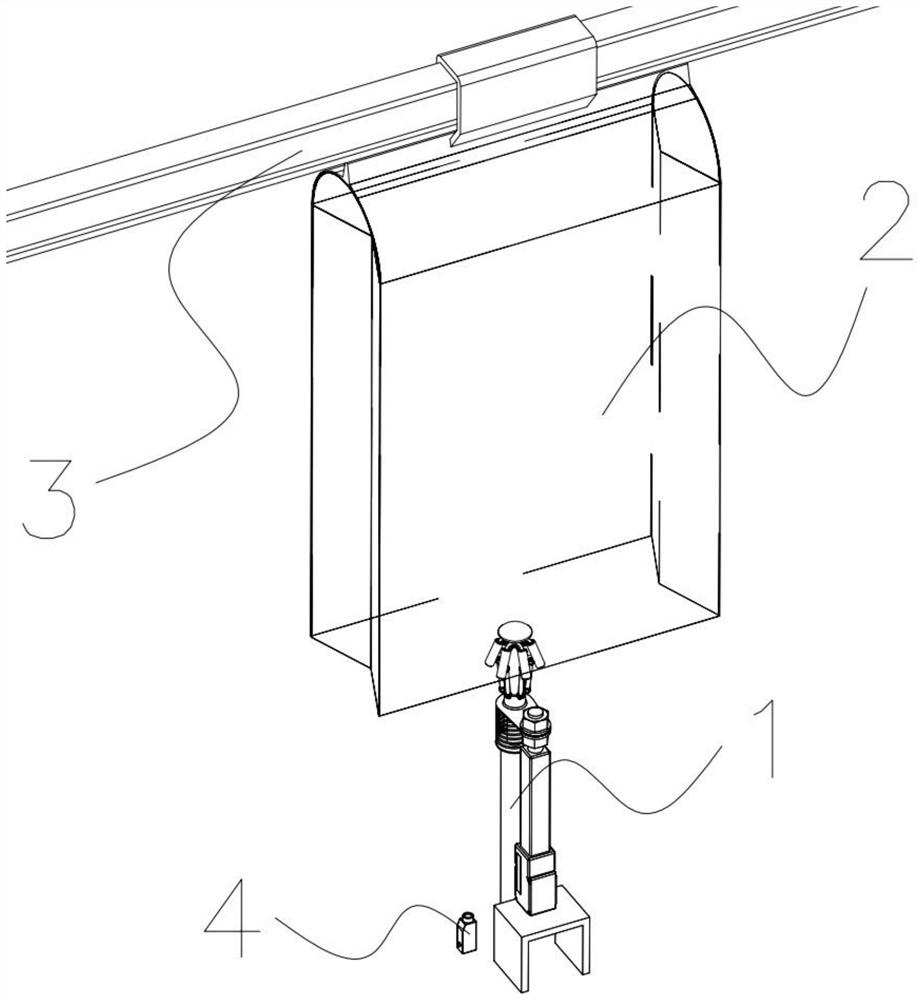

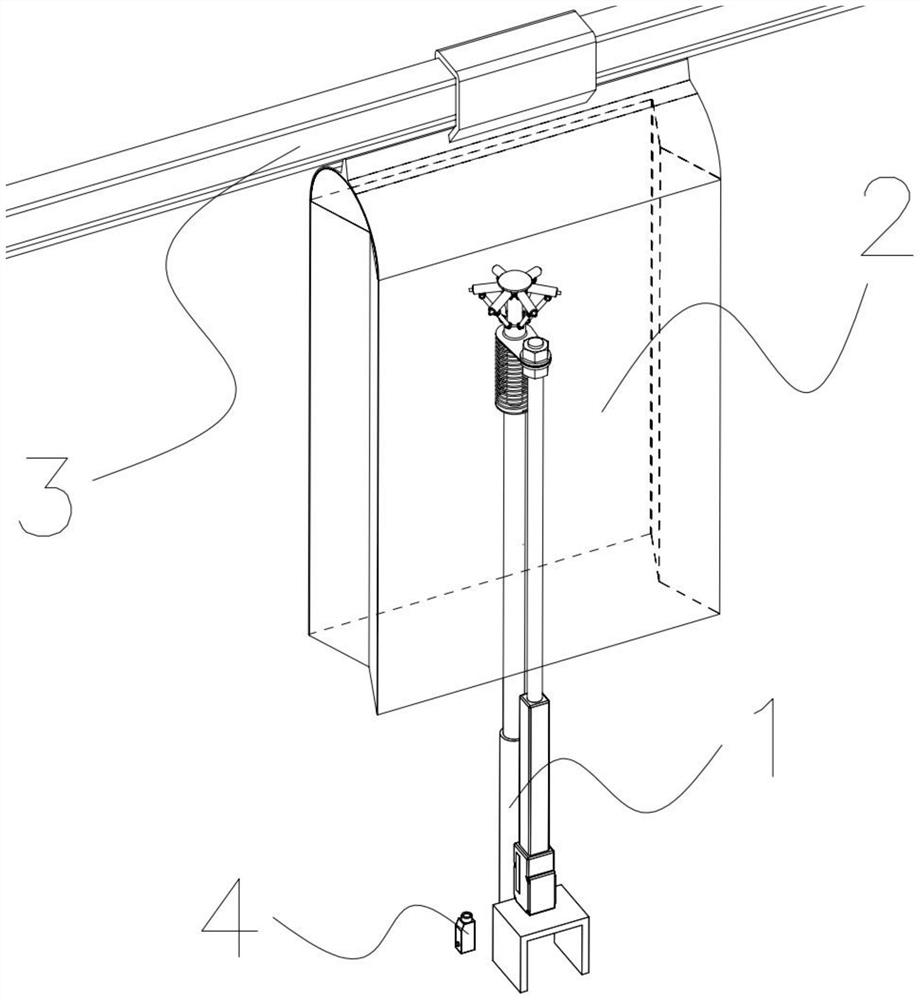

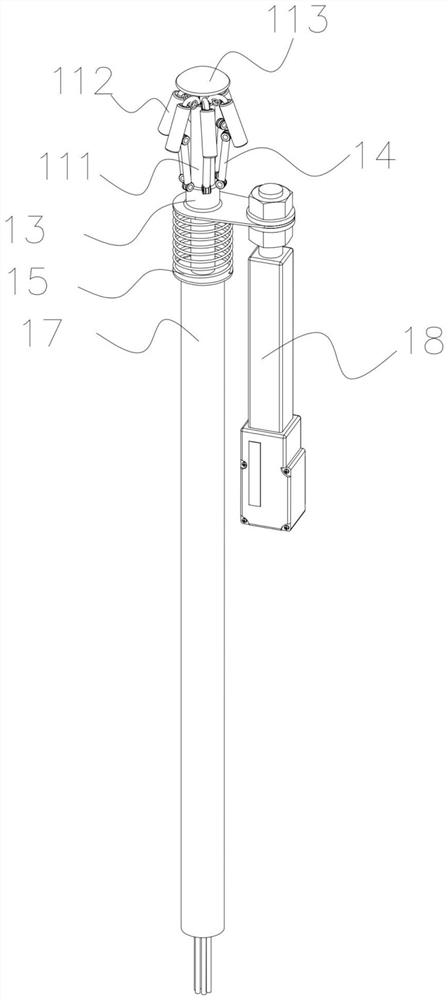

[0040] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention. The present invention is described in detail by using structural schematic diagrams, etc., and the schematic diagrams are only examples, which should not limit the protection scope of the present invention. In addition, the three-dimensional space of length, width and depth should be included in actual production.

[0041] see Figure 1-Figure 11 , a device for cleaning the interior of a woven bag 2, comprising a woven bag clamping conveyor belt 3, the mouth of the woven bag 2 facing downwards, a telescopic rod 1 is arranged below the woven bag clamping conveyor belt 3, and the telescopic rod 1 is internally arranged There are several air pipes 12, the ports o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap