Method for producing non-woven fabric based on polypropylene powder modification

A polypropylene powder, non-woven technology, applied in the direction of one-component polyolefin rayon, non-woven fabrics, textiles and papermaking, etc., can solve the problems of poor air permeability, easy to generate static electricity, low moisture content and other problems of non-woven fabrics , to achieve the effect of improving antistatic performance, avoiding excessive waste, and improving antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

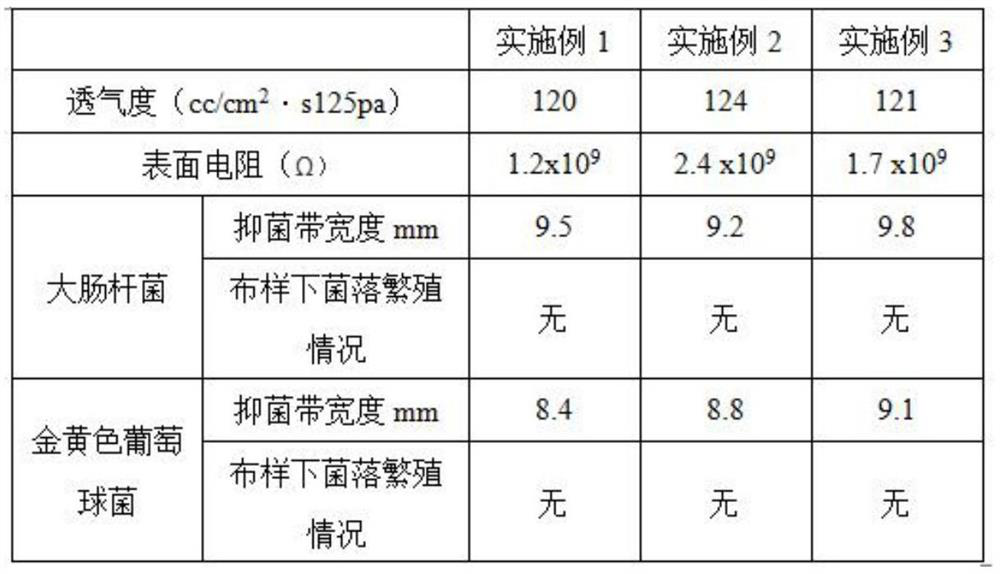

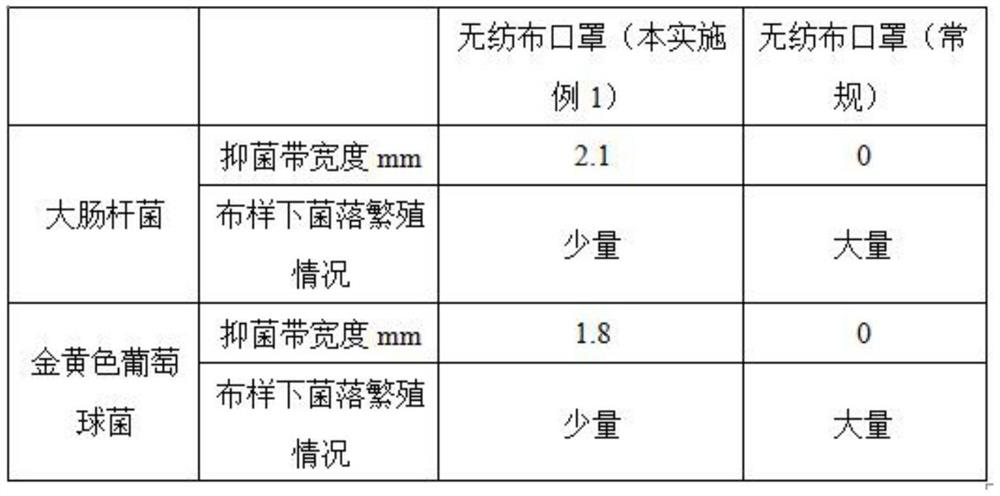

Embodiment 1

[0024] A method for producing non-woven fabrics based on polypropylene powder modification, comprising the following steps:

[0025] A) Preparation of modified aerosol: Heat and cook the coconut shell, firstly raise the heating temperature to 100°C for 35 minutes, then raise the temperature to 120°C for 6 minutes, and the heating rate is 3°C / min to obtain the cooking residue, then Fermentation and enzymolysis treatment are carried out to obtain coconut shell fiber, the fermentation temperature is 50°C, the fermentation time is 2h, the enzymolysis temperature is 20°C, and the enzymolysis time is 12h, and the obtained coconut shell fiber is dried until the water content of the coconut shell fiber is 6%. Carry out ultrafine pulverization, the ultrafine pulverization particle size of coconut shell fiber is 200 mesh, add deionized water to dissolve to make fiber solution, drying temperature is 70 ℃, drying time is 4h, and finally put into ultrasonic aerosol generating device to reac...

Embodiment 2

[0029] A method for producing non-woven fabrics based on polypropylene powder modification, comprising the following steps:

[0030] A) Preparation of modified aerosol: Heat and cook the coconut shell, firstly raise the heating temperature to 110°C for 30 minutes, then raise the temperature to 128°C for 5 minutes, and the heating rate is 2°C / min to obtain cooking slag, then Perform fermentation and enzymolysis treatment to obtain coconut shell fiber, the fermentation temperature is 60°C, the fermentation time is 1h, the enzymolysis temperature is 30°C, and the enzymolysis time is 14h, and the obtained coconut shell fiber is dried until the water content of the coconut shell fiber is 5%. Carry out ultrafine pulverization, the ultrafine pulverization particle size of coconut shell fiber is 300 mesh, add deionized water to dissolve and make fiber solution, drying temperature is 55 ℃, drying time is 6h, and finally put into ultrasonic aerosol generating device to react to obtain mo...

Embodiment 3

[0034] A method for producing non-woven fabrics based on polypropylene powder modification, comprising the following steps:

[0035] A) Preparation of modified aerosol: Heat and cook the coconut shell, firstly raise the heating temperature to 105°C for 32 minutes, then raise the temperature to 126°C for 8 minutes, and the heating rate is 4°C / min to obtain cooking slag, then Carry out fermentation and enzymolysis treatment to obtain coconut shell fiber, the fermentation temperature is 54°C, the fermentation time is 1.3h, the enzymolysis temperature is 25°C, and the enzymolysis time is 13h, and the obtained coconut shell fiber is dried until the water content of the coconut shell fiber is 10%. , carry out ultra-fine grinding, coconut shell fiber ultra-fine grinding particle size is 250 mesh, add deionized water to dissolve and make fiber solution, drying temperature is 60 ℃, drying time is 5h, and finally put into ultrasonic aerosol generating device to react to obtain modificati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com