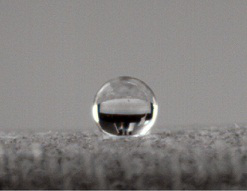

Super-hydrophobic flexible fabric pressure sensor based on silver nanowires and preparation method of super-hydrophobic flexible fabric pressure sensor

A pressure sensor, super-hydrophobic and flexible technology, applied in the field of wearable sensors, can solve the problems of weak conductivity, single function of conductive fabrics, poor adhesion between conductive materials and fabrics, etc., to achieve good conductivity, suitable for large-scale manufacturing, high The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Said a kind of superhydrophobic flexible all-fabric pressure sensor based on nano-silver wire and its preparation method:

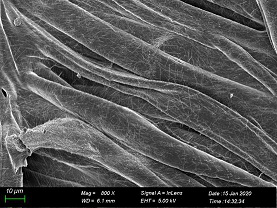

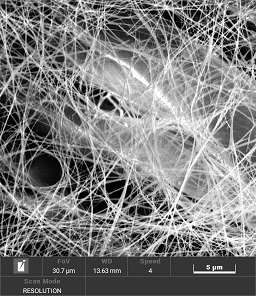

[0030] (1) Dissolve 2 grams of hydroxymethyl cellulose in 100 ml of aqueous solution completely, then add 0.5 grams of aqueous polyurethane solution to it, stir for 10 minutes at 1500~2000 rpm / min, and then add 8 grams of nano silver wire , stirred for 30 minutes under the condition of 1500-2000 rpm / min, and prepared into silver nano wire ink.

[0031] (2) Place the designed screen printing screen on a clean fabric, fix the screen and put the nano-silver wire conductive ink on the screen, and use a scraper to scrape the nano-silver wire ink on the screen, The number of times of scraping is 20 times. After the scraping is completed, the screen is slowly lifted from one side, and a clear circuit can appear on the surface of the fabric. Put the printed circuit fabric into a drying oven at 70-80°C for 15-30 minutes to dry to obtain the bottom electrod...

Embodiment 2

[0037] Described a kind of superhydrophobic antibacterial conductive fabric and preparation method thereof:

[0038](1) Completely dissolve 3.5 grams of hydroxymethyl cellulose in 100 ml of aqueous solution, then add 1 gram of aqueous polyurethane solution to it, stir for 10 minutes at 1500~2000 rpm / min, and then add 15 grams of nano silver wire , stirred for 30 minutes under the condition of 1500-2000 rpm / min, and prepared into silver nano wire ink.

[0039] (2) Place the designed screen printing screen on a clean fabric, fix the screen and put the nano-silver wire conductive ink on the screen, and use a scraper to scrape the nano-silver wire ink on the screen, The number of times of scraping is 10 times. After the scraping is completed, the screen is slowly lifted from one side, and a clear circuit can appear on the surface of the fabric. Put the printed circuit fabric into a drying oven at 70-80° C. for 15-30 minutes to dry to obtain the bottom electrode of the conductive ...

Embodiment 3

[0045] Described a kind of superhydrophobic antibacterial conductive fabric and preparation method thereof:

[0046] (1) Completely dissolve 2 grams of hydroxymethyl cellulose in 100 ml of aqueous solution, then add 0.5 grams of aqueous polyurethane solution, stir for 10 minutes at 1500~2000 rpm / min, and then add 15 grams of nano silver wire , stirred for 30 minutes under the condition of 1500-2000 rpm / min, and prepared into silver nano wire ink.

[0047] (2) Place the designed screen printing screen on a clean fabric, fix the screen and put the nano-silver wire conductive ink on the screen, and use a scraper to scrape the nano-silver wire ink on the screen, The number of times of scraping is 10 times. After the scraping is completed, the screen is slowly lifted from one side, and a clear circuit can appear on the surface of the fabric. Put the printed circuit fabric into a drying oven at 70-80° C. for 15-30 minutes to dry to obtain the bottom electrode of the conductive fabr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com