Hydrogen leakage monitoring device for hydrogen-oxygen fuel cell

A fuel cell and monitoring device technology, applied to fuel cells, liquid tightness measurement using liquid/vacuum, circuits, etc., can solve problems such as explosion, poor adaptability, and difficult detection, etc., to achieve wide adaptability, Ease of replacement and reduced risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

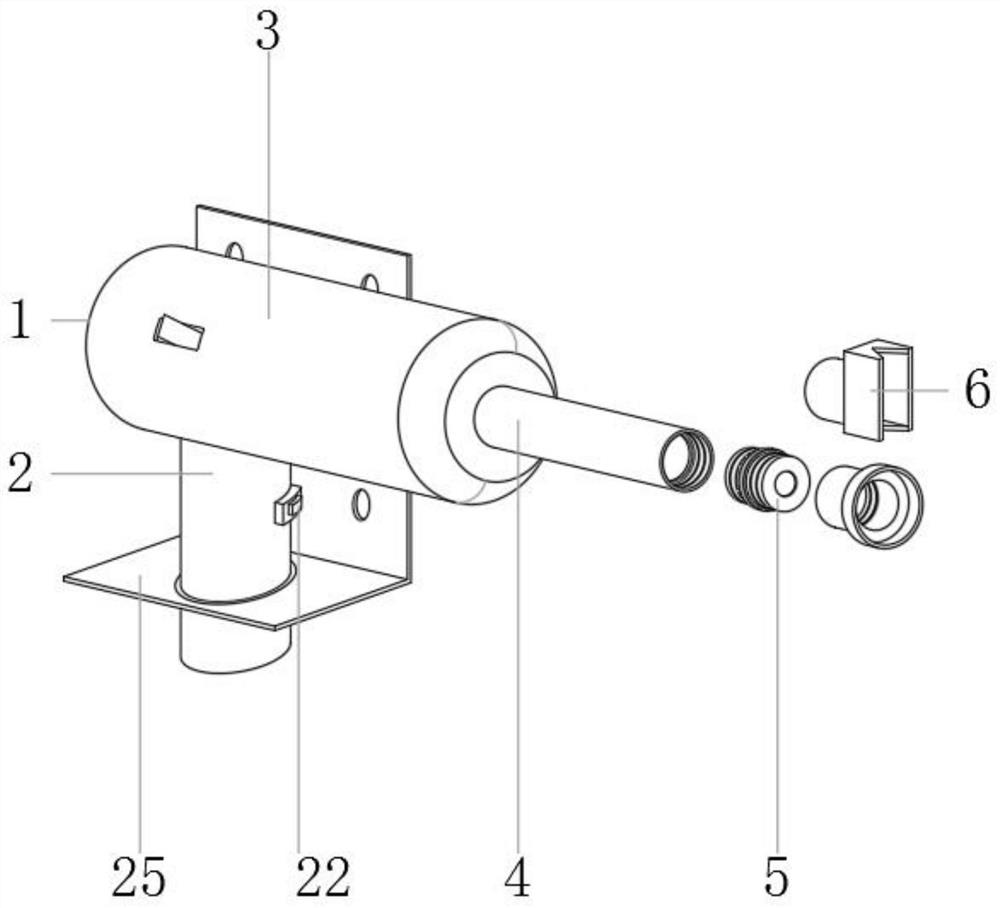

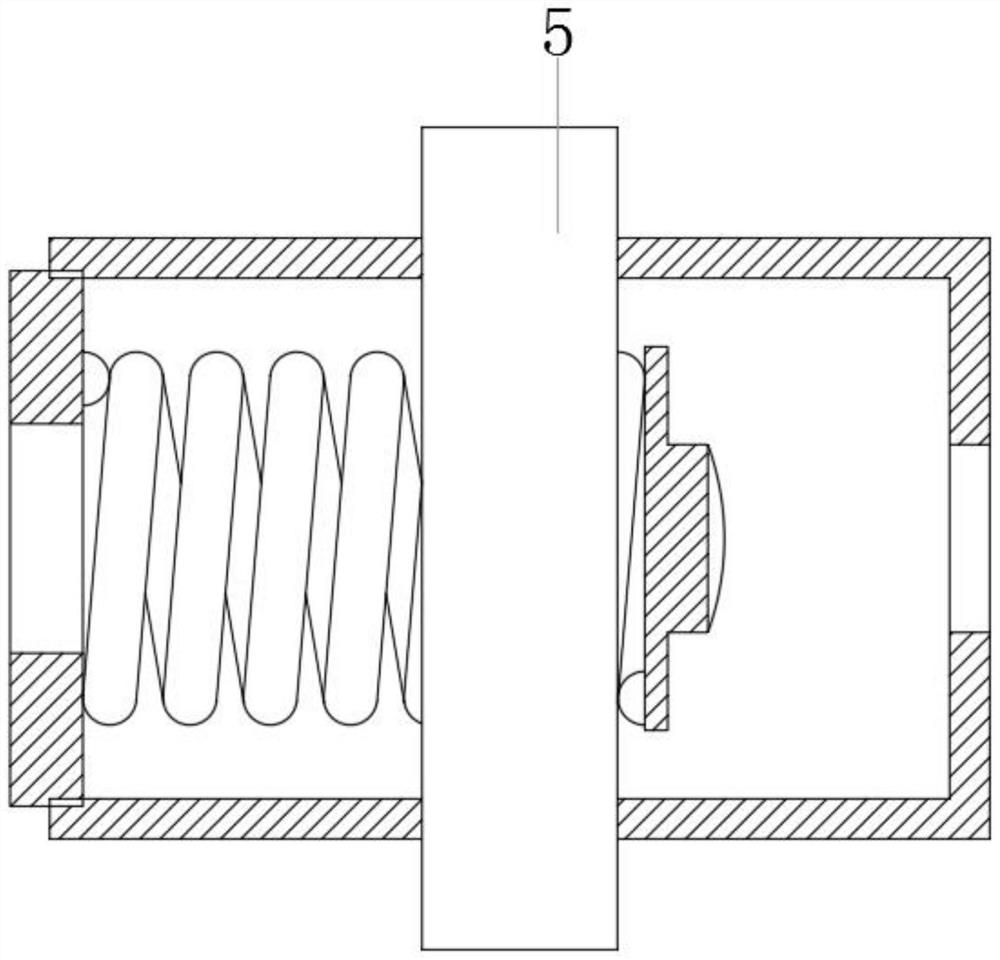

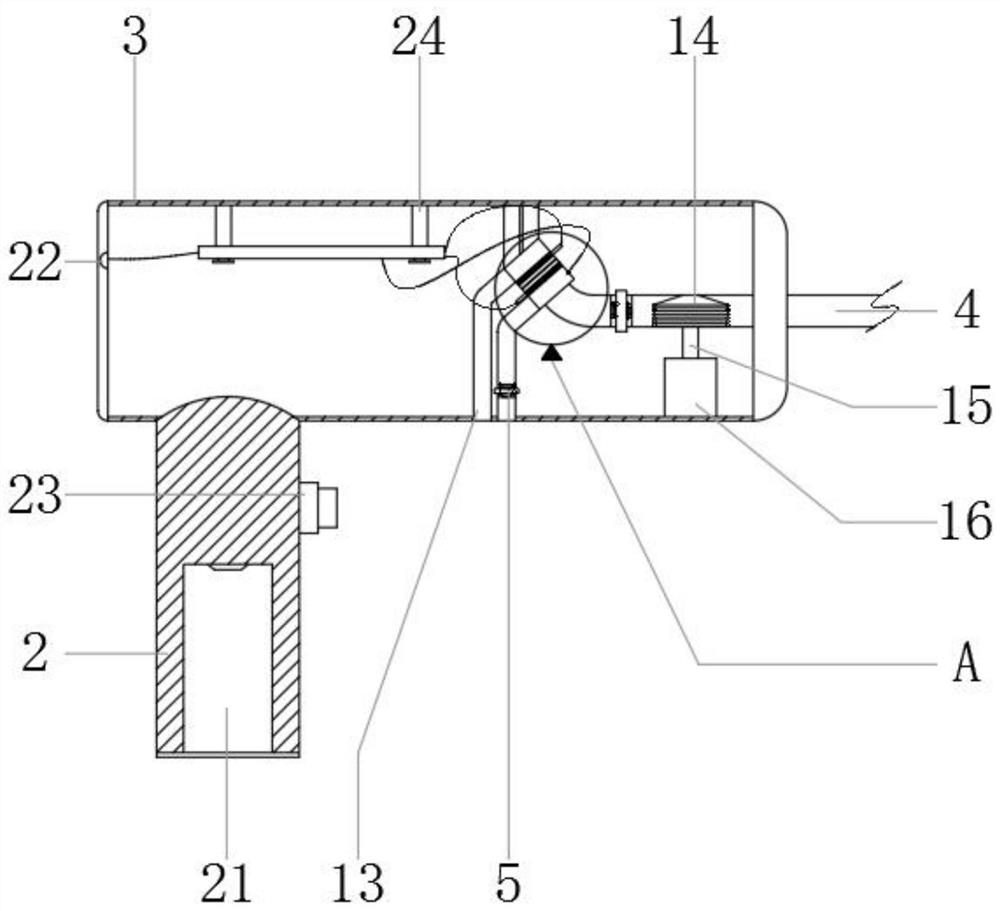

[0025] refer to Figure 1-6 , a hydrogen leakage monitoring device for hydrogen-oxygen fuel cells, including a housing 1, the housing 1 includes a handle 2 and a cylindrical shell 3, the handle 2 is convenient for the inspector to hold the device for detection, and the inner surface of the cylindrical shell 3 is inserted Connected with a straight pipe 4, the straight pipe 4 is the channel through which the hydrogen gas leaked from the detected battery is sucked into the reaction cylinder 8. The inner surface of the straight pipe 4 is threaded with a one-way valve 5, and the initial state of the inner spring of the one-way valve 5 is a compressed state , so that the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com