Sampling method for bulk coal car

A technology of coal cars and carriages, which is applied in the field of sampling of bulk coal cars, can solve problems such as the collision between the sampling head and the tie bars, frequent operations by operators, and sampling failures, so as to prevent manual work errors, ensure sampling effects, and increase representativeness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

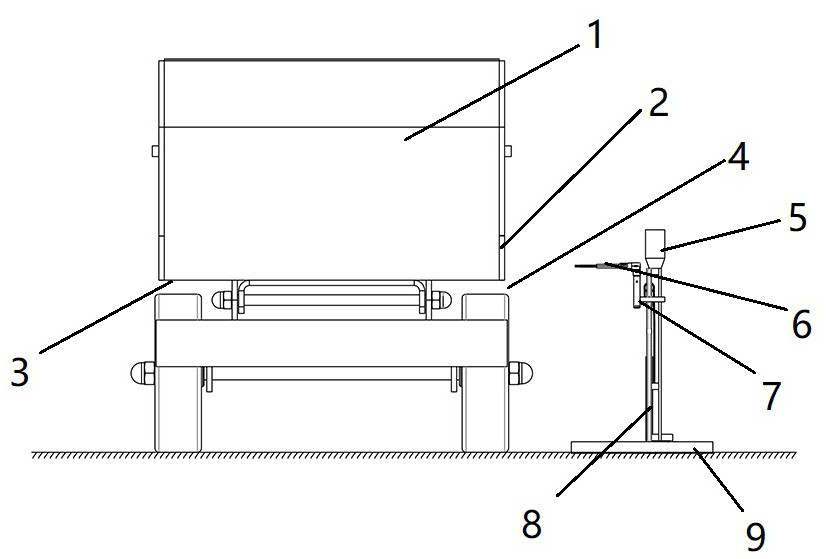

[0037] A kind of bulk coal car sampling method, comprises the following steps:

[0038] Step 1. Prepare the control sample dataset:

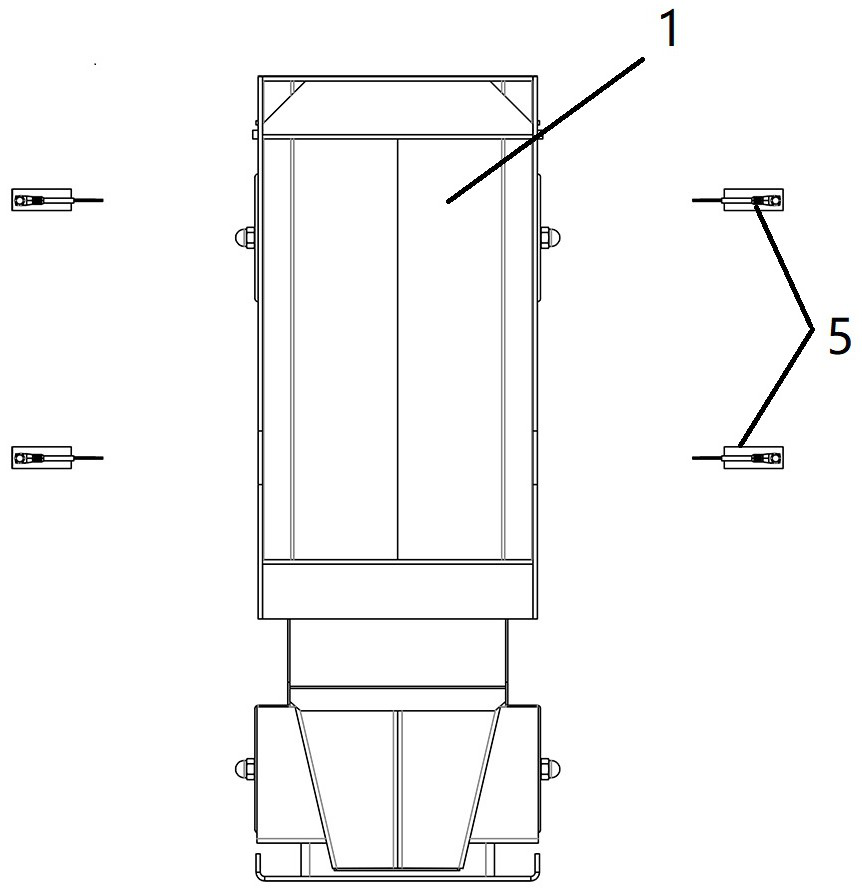

[0039] 1.1 Collecting sample data: The camera takes multiple overhead images of the coal-scattering carriage, manually detects the captured images, and saves the qualified images to the sample image library;

[0040] 1.2 Manually mark the images in the sample image library, use rectangular frames to select the stretch bars, carriage bodies, and loose coal stacking areas, and mark the selected feature categories. Each sample image generates an .xml file. In the .xml file Including the image name, image storage location, frame-selected car body, stretch bars, loose coal stacking area, and the position of the stretch area covered by coal seams, the horizontal and vertical coordinates of the upper left corner of the manually marked rectangular frame of each feature category and The horizontal and vertical coordinates of the lower right corner of th...

Embodiment 2

[0062]In this embodiment, different from Embodiment 1, in step 2: two sets are respectively arranged on both sides of the compartment, and four compartment height identification devices are arranged on both sides, which are compartment height identification device A and compartment height identification device A respectively. Identification device B, compartment height identification device C, and compartment height identification device D, the four compartment height identification devices respectively measure the compartment floor heights Za, Zb, Zc, and Zd at four positions, and the obtained four compartment floor heights Za . The distances d1, d2, d3, and d4 between the height recognition device C and the side panels of the compartment measured respectively can be obtained from the compartment height recognition device A, the compartment height recognition device B, the compartment height recognition device C, and the compartment height recognition device D. For the absolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com