Modified sealing agent and preparation method thereof

A technology of blocking agent and modifying agent, which is applied in the field of modified blocking agent and its preparation, can solve the problems of false negative stability, incomplete blocking, and affecting sensitivity, etc., and achieve improved stability, good dispersibility, and reduced interprotein The effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

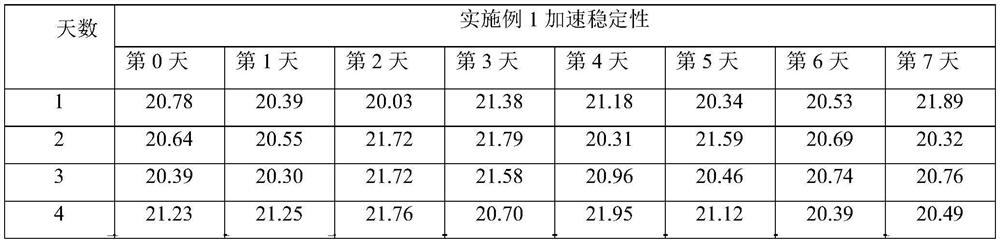

Embodiment 1

[0022] A modified sealing agent, comprising the following raw materials in parts by weight: 15 parts of sheep serum albumin, 5 parts of ovalbumin, 6 parts of gelatin, 50 parts of modifiers, 80 parts of modifiers, and 100 parts of chondroitin sulfate; The active agent is a combination of p-dodecylbenzenesulfonyl azide and disodium dithiobutamate according to the mass ratio of 4:1; the modifier is cysteine desulfurase and biotin according to the mass ratio of 1:7 The combination;

[0023] (1) adding water to sheep serum albumin and ovalbumin for dilution, then adding gelatin therein and stirring to mix evenly to obtain protein liquid;

[0024] (2) Add a modifying agent to the protein solution and mix evenly, then place it at a temperature of 37°C and stir for 15 minutes to obtain a modified protein solution, add a modifying agent to the modified protein solution, and continue to stir and react at a temperature of 37°C for 15 minutes to obtain Modifying the protein solution, c...

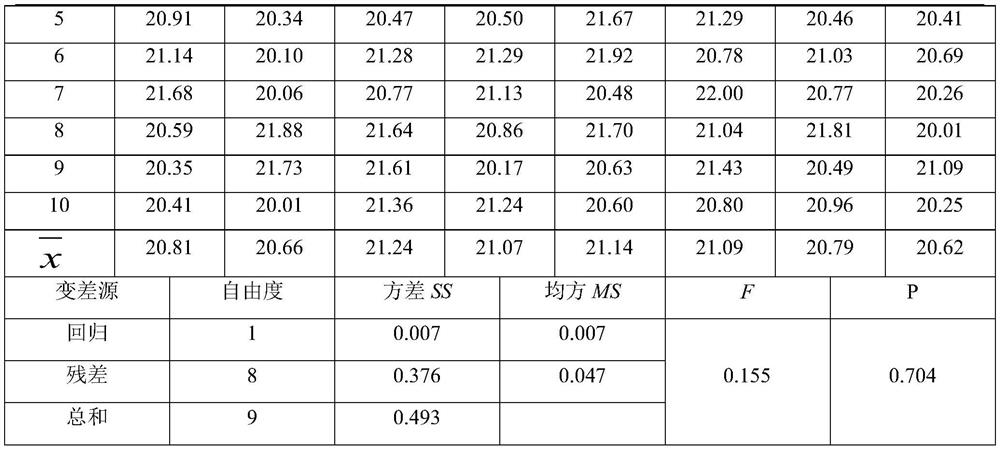

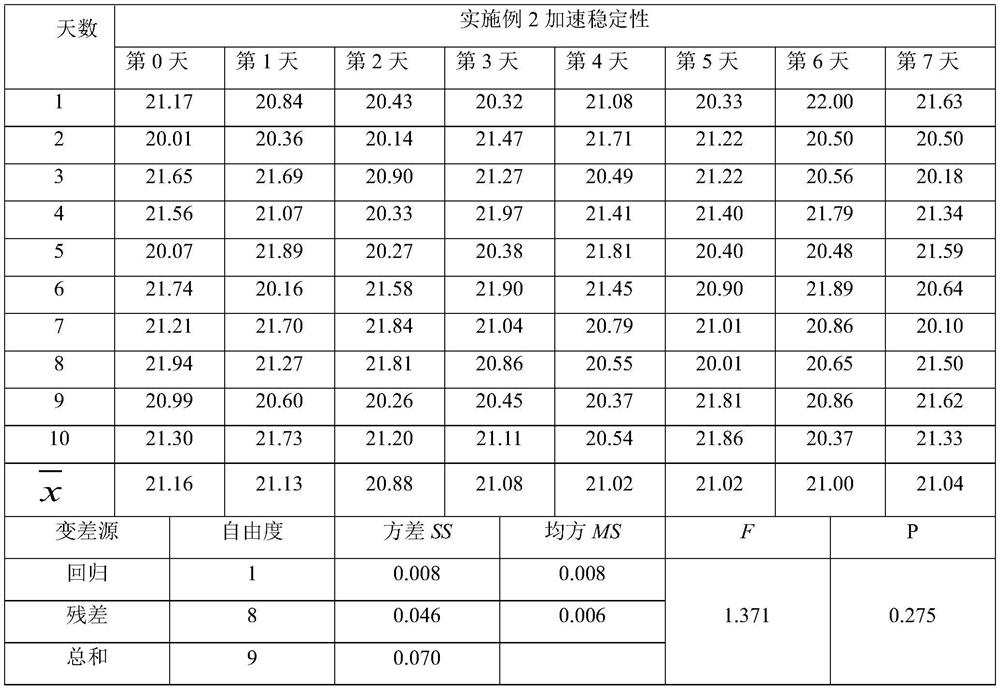

Embodiment 2

[0027] A modified sealing agent, comprising the following raw materials in parts by weight: 5 parts of sheep serum albumin, 1 part of gelatin, 20 parts of modifiers, 30 parts of modifiers, 50 parts of chondroitin sulfate; The combination of alkylbenzenesulfonyl azide and disodium dithiobutamate according to the mass ratio of 1:5; the modifier is the combination of cysteine desulfurase and biotin according to the mass ratio of 10:1;

[0028] (1) adding water to sheep serum albumin and ovalbumin for dilution, then adding gelatin therein and stirring to mix evenly to obtain protein liquid;

[0029] (2) Add a modifying agent to the protein solution and mix evenly, then place it at a temperature of 36°C and stir for 12 minutes to obtain a modified protein solution, add a modifying agent to the modified protein solution, and continue to stir and react at a temperature of 36°C for 12 minutes to obtain Modifying the protein solution, centrifuging the modified protein solution to sep...

Embodiment 3

[0032] A modified sealing agent, comprising the following raw materials in parts by weight: 8 parts of sheep serum albumin, 1 part of ovalbumin, 2 parts of gelatin, 30 parts of modifiers, 50 parts of modifiers, 60 parts of chondroitin sulfate; The active agent is a combination of p-dodecylbenzenesulfonyl azide and disodium dithiobutamate according to the mass ratio of 2:1; the modifier is cysteine desulfurase and biotin according to the mass ratio of 1:4 The combination;

[0033] (1) adding water to sheep serum albumin and ovalbumin for dilution, then adding gelatin therein and stirring to mix evenly to obtain protein liquid;

[0034] (2) Add a modifying agent to the protein solution and mix evenly, then place it at a temperature of 37°C and stir for 10 minutes to obtain a modified protein solution, add a modifying agent to the modified protein solution, and continue to stir and react at a temperature of 37°C for 10 minutes to obtain Modifying the protein solution, centrifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com