Back contact solar cell, assembly, preparation method and system

A solar cell and back contact technology, applied in the field of solar cells, can solve the problems of cumbersome interconnection process, increase the cost of battery components, increase the interconnection process of sub-cells, etc., achieve simplified interconnection process, high component power potential, reduce The effect of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

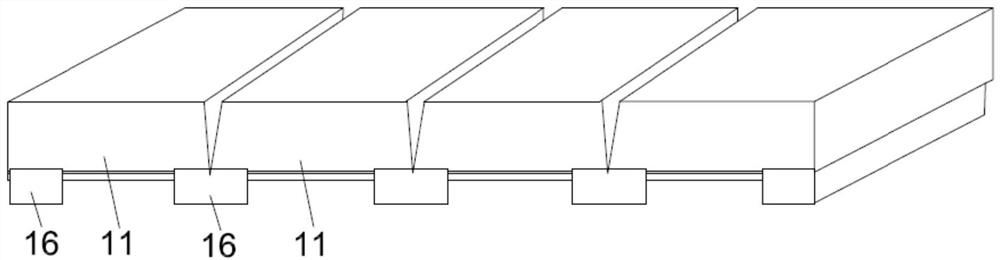

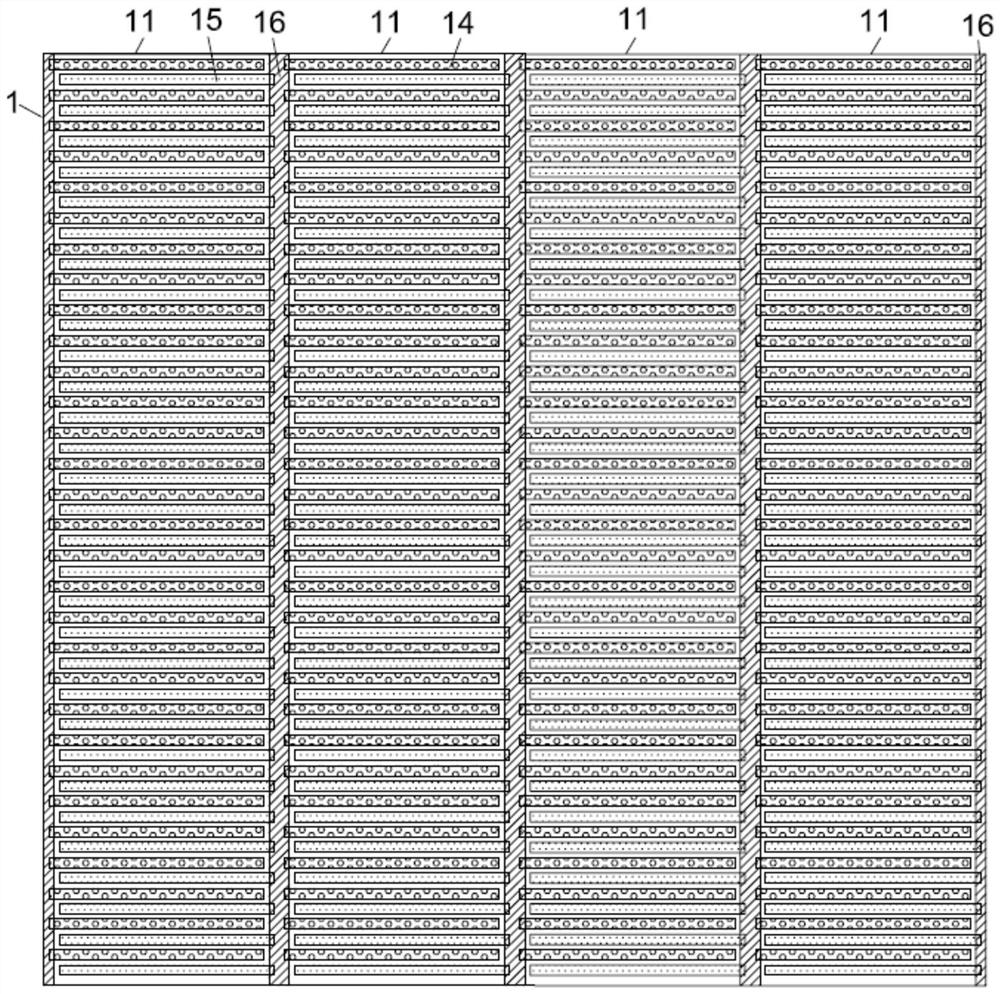

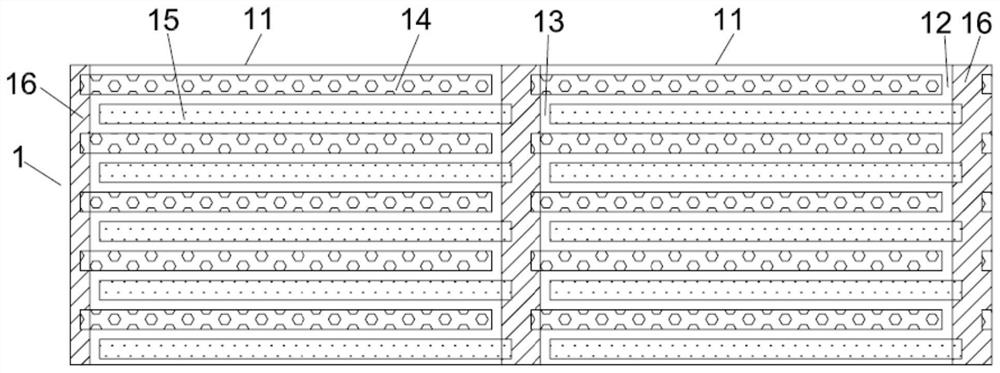

[0031] The preparation method of a kind of back contact solar cell assembly of the present embodiment, refer to Figure 1-3 , including the following steps:

[0032] Step S1, prepare the main grid electrode 16 on the back surface of the battery to divide the battery into several sub-cells 11, each sub-cell 11 is prepared with alternately arranged base electrodes 15 and emitter electrodes 14, and in each sub-cell 11, each The current of the emitter electrode 14 converges on the same main grid electrode 16, and the current of each base electrode 15 converges on the other main grid electrode 16, that is, the back contact solar cell 1 is obtained; for the specific structure, refer to Figure 2-3 .

[0033] Among them, step S1 is preferably to prepare the emitter electrode 14, the base electrode 15 and the main grid electrode 16 by screen printing (that is, the back electrode of the back contact solar cell 1 includes the emitter electrode 14, the base electrode 15 and the main gri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com