Roller automatic assembly line

A technology of automatic assembly and supporting rollers, which is applied in the directions of transportation and packaging, engine components, engine lubrication, etc., can solve problems such as high labor intensity, achieve the effect of reducing labor intensity, facilitating management, and reducing manual participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

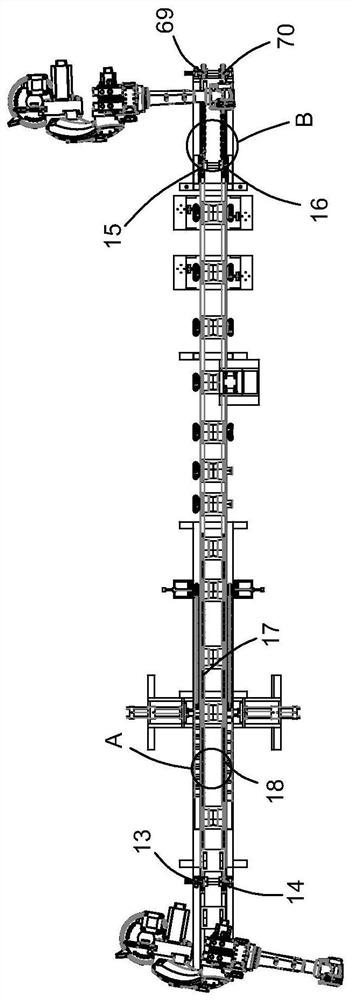

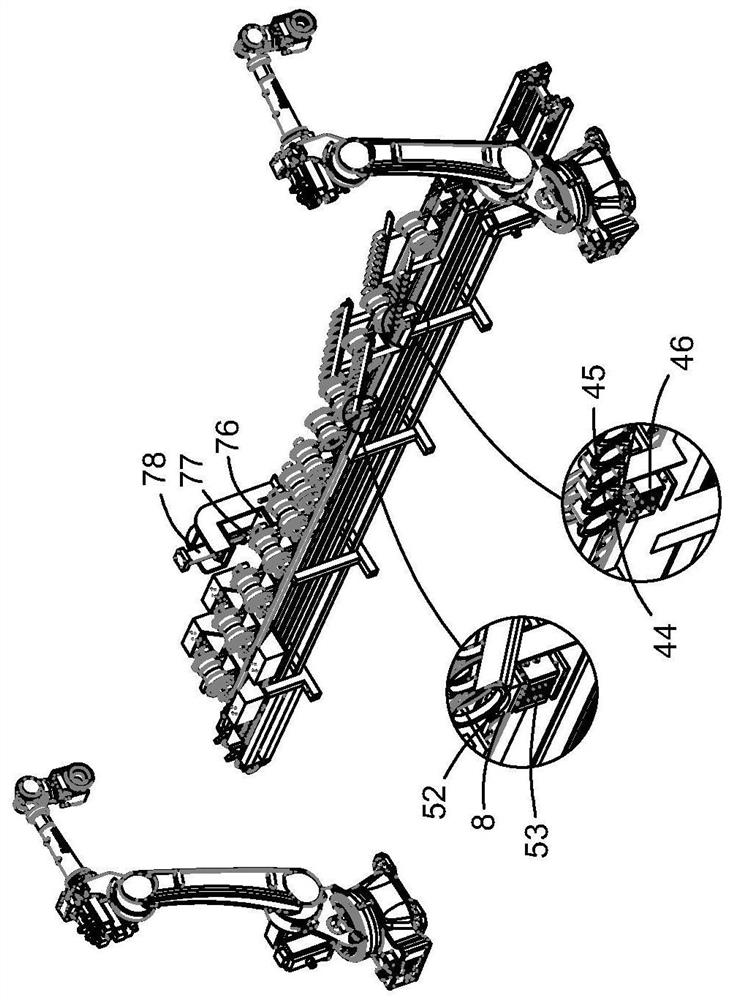

[0054] refer to Figure 1 to Figure 14 , the embodiment of the present invention discloses an automatic assembly production line for rollers, including a frame 10, the two ends of the frame 10 are respectively rotatably provided with a first rotating shaft 11 and a second rotating shaft 12 through bearings. Both ends of the first rotating shaft 11 are respectively provided with a first sprocket 13 and a second sprocket 14 , and both ends of the second rotating shaft 12 are respectively provided with a third sprocket 15 and a fourth sprocket 16 . The first sprocket, the second sprocket, the third sprocket and the fourth sprocket are respectively fixed with a shaft sleeve, the shaft sleeve is provided with a locking hole along the vertical axial direction, and a locking hole is arranged in the locking hole. A locking member, the locking hole is a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com