Production device for fiber-reinforced tire-free asphalt waterproof coiled material and waterproof coiled material

A bitumen waterproof membrane and fiber-reinforced technology, which is applied in lamination devices, layered products, synthetic resin layered products, etc., can solve the problems of product quality and construction quality decline, waterproof membranes are prone to wrinkles, etc., and achieve improvement Quality and construction performance, improvement of product quality, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

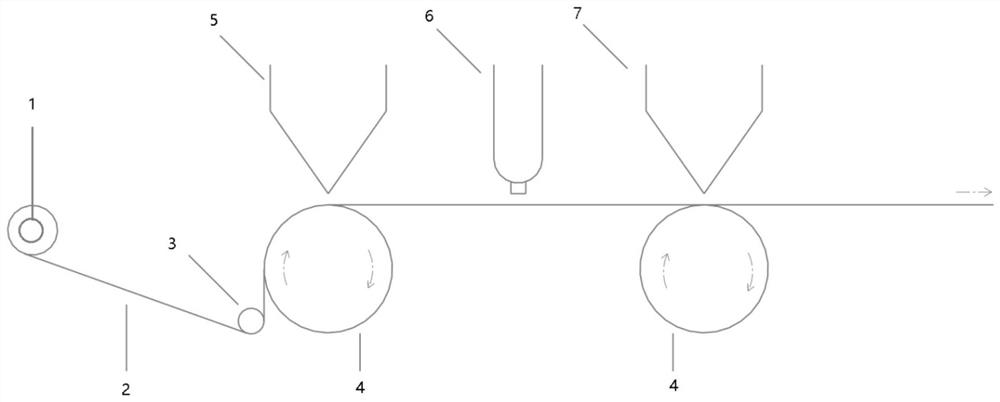

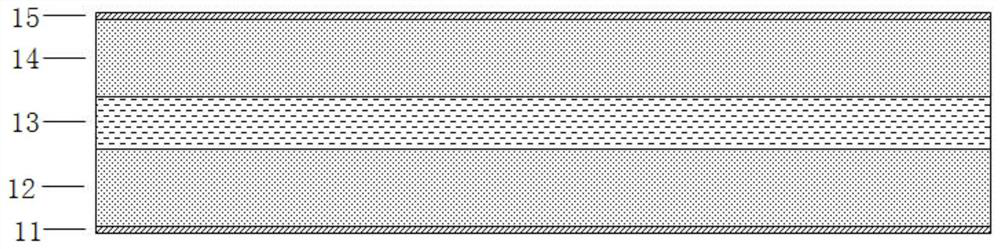

[0053] figure 1 A schematic structural diagram of the fiber-reinforced tireless asphalt waterproofing membrane production device of the present embodiment is shown; figure 2 A schematic structural diagram of the fiber-reinforced tireless bitumen waterproofing membrane of this embodiment is shown.

[0054] This embodiment provides a fiber-reinforced tireless asphalt waterproofing membrane production device, such as figure 1 As shown, it includes: a flattening mechanism, a transmission mechanism, a first coating mechanism 5, a reinforcement layer coating mechanism, a second coating mechanism 7 and a film coating mechanism; the flattening mechanism includes a first support roller 1 and a flattening roller 2 , the first supporting roller 1 is used to install the material roll of the first isolation layer, the flattening roller 2 is arranged between the first supporting roller 1 and the transmission mechanism, the axis of the flattening roller 3 is parallel to the axis of the fir...

Embodiment 2

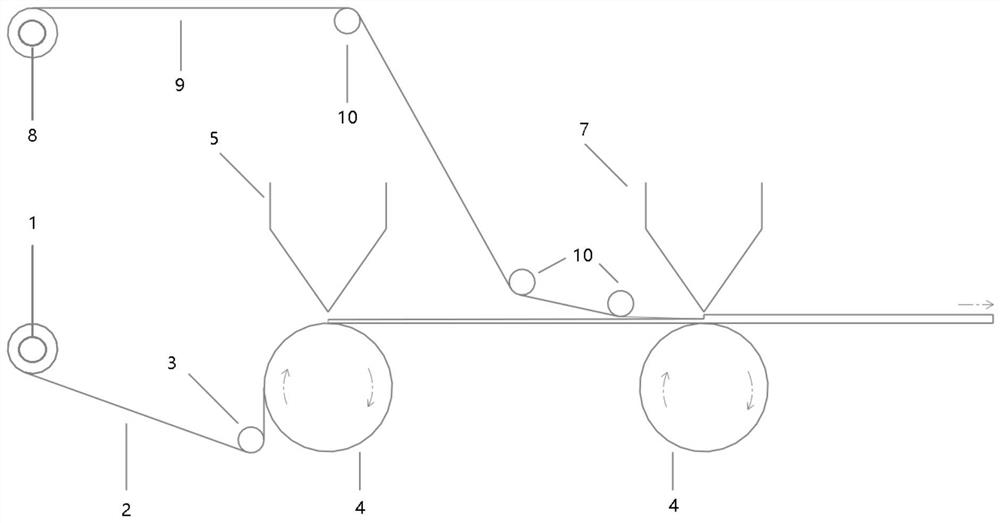

[0065] image 3 A schematic structural diagram of the fiber-reinforced tireless asphalt waterproofing membrane production device of the present embodiment is shown; Figure 4 A schematic structural diagram of the fiber-reinforced tireless bitumen waterproofing membrane of this embodiment is shown.

[0066] The difference between the fiber-reinforced tireless asphalt waterproofing membrane production device in this embodiment and the fiber-reinforced tireless asphalt waterproofing membrane production device in Embodiment 1 is that the reinforcing layer coating mechanism in this embodiment includes a second support roller 8 and three guide rollers 10, the second support roller 8 is used to install the material roll of the fiber reinforced layer, and the three guide rollers 10 are successively arranged between the second support roller 8 and the transmission mechanism and are parallel to each other, and the three guide rollers 10 It is used to guide the fiber-reinforced layer on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com