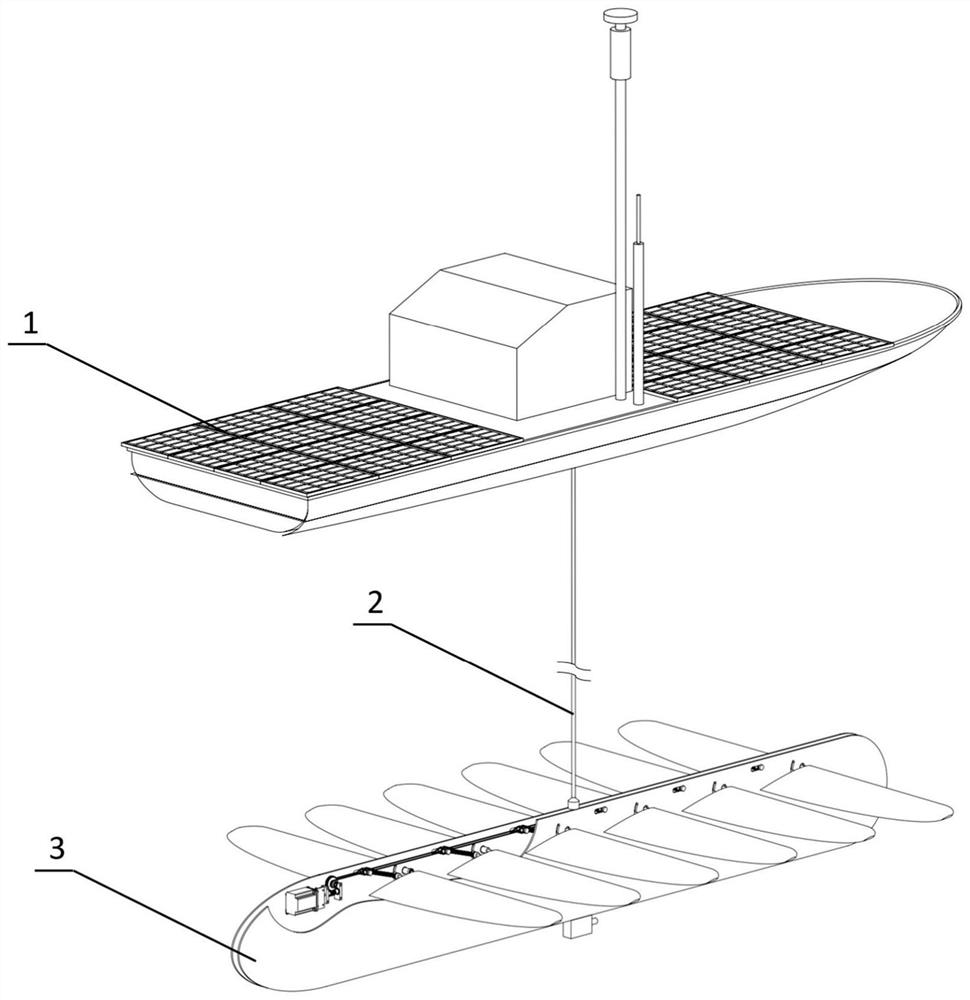

A variable torsional stiffness underwater tractor hydrofoil system for gliders

A technology of torsional stiffness and tractor, applied in the field of ships and marine engineering, can solve the problems of random wave conditions, large changes, difficult to achieve optimal performance, etc., to achieve high adaptability, reduce requirements, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

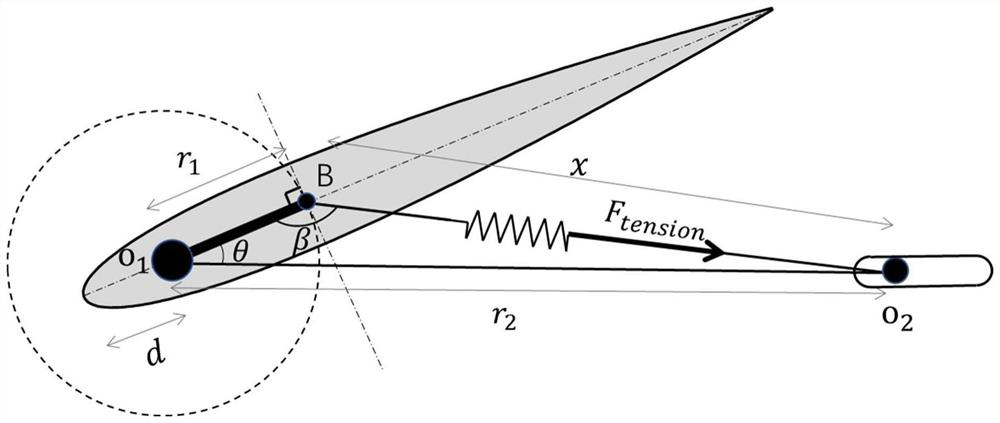

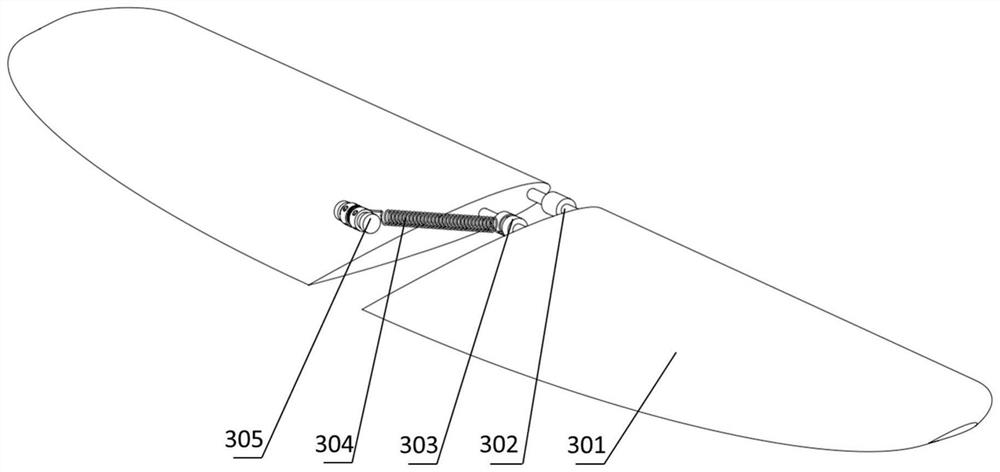

[0060] like Figure 4 As shown, it is an underwater tractor including a straight-pull hydrofoil stiffness adjustment system, including a hydrofoil pitch motion unit, a stiffness adjustment system, a speed sensing unit, and a mounting plate frame assembly. The hydrofoil pitching motion unit includes a hydrofoil 301, a fixed rotating shaft 302, a motion shaft 303, a spring 304, and a spring connecting pin 305. The stiffness adjustment system includes a wire rope 306, a worm gear transmission structure 307, and a motor 308. The speed sensing unit includes The inertial sensor 309, the flow velocity sensor 310, and the mounting plate assembly include side plates 311 and other connecting fasteners.

[0061] The inertial sensor 309 and the flow velocity sensor 310 are installed independently, wherein the flow velocity sensor is installed in front of the underwater tractor to avoid interference by the hydrofoil wake,

[0062] The underwater tractor has 6 pitching motion units, and th...

Embodiment 2

[0066] like Figure 5 As shown, it is an underwater tractor including a rigid sliding link type hydrofoil stiffness adjustment system, including a hydrofoil pitching motion unit, a stiffness adjustment system, a speed sensing unit, and a mounting plate frame assembly. The hydrofoil pitching motion unit includes a hydrofoil 301, a fixed rotating shaft 302, a moving shaft 303, a spring 304, and a spring connecting pin 305. The stiffness adjustment system includes a linear bearing module 312, an adapter part 313, a sliding link 314, a wire The rod nut mechanism 315 , the motor 308 , the speed sensing unit includes an inertial sensor 309 , a flow velocity sensor 310 , and the mounting plate assembly includes a side plate 311 .

[0067] Both the inertial sensor 309 and the flow rate sensor 310 can be strap-down mounted.

[0068] The underwater tractor has 6 pitching motion units, and the fixed rotating shaft 302 is installed on the side plate 311 . There are six grooves with a le...

Embodiment 3

[0072] like Image 6 As shown, it is an underwater tractor including a straight-pull hydrofoil stiffness adjustment system, including a hydrofoil pitch motion unit, a stiffness adjustment system, a speed sensing unit, and a mounting plate frame assembly. The hydrofoil pitching motion unit includes a hydrofoil 301, a fixed rotating shaft 302, a moving shaft 303, a spring 304, and a spring connecting pin 305. The stiffness adjustment system includes a wire rope 306, a worm gear transmission structure 307, a motor 308, and a fixed pulley 317. The speed sensing unit includes an inertial sensor 309 , a flow velocity sensor 310 , and the mounting plate assembly includes a side plate 311 .

[0073] The third embodiment is roughly the same as the first embodiment, except that a fixed pulley structure is added. After adding the fixed pulley structure, the position of the spring connecting pin 305 can be moved downward, thereby preventing the interference between the wire rope 306 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com