Preparation method of saccharomycetes for fermented glutinous rice cake-shaped chilies

A technology of glutinous rice cake chili and yeast, which is applied in the field of yeast preparation based on fermented glutinous rice cake chili, can solve the problems of high spicy salinity of glutinous rice cake chili and low fermentation activity of yeast, so as to achieve sufficient reaction, improve pungency, and increase richness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

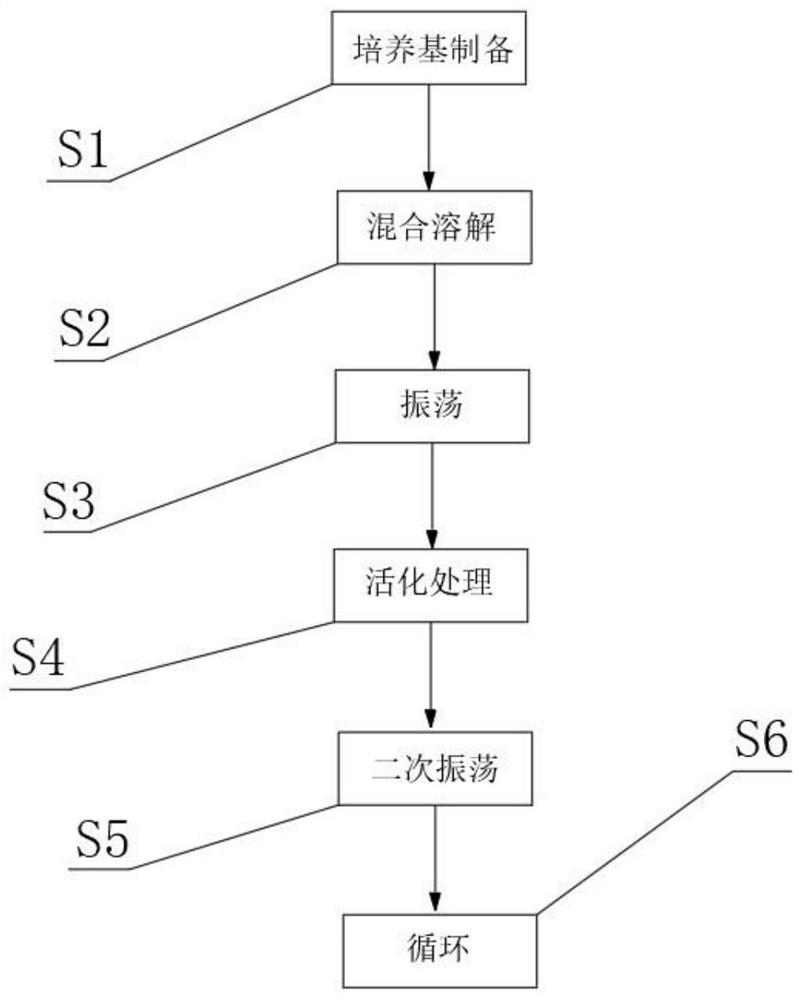

[0025] The present invention is realized through the following contents: S1. medium preparation, preparing YPD liquid medium, adding yeast, and the yeast is L. Bacteria powder; S3. Shake, put the cultured yeast into the shaker to shake; S4. Activation treatment, add the activated bacteria liquid to the yeast after shaking culture; S5. Secondary shaking, the activated yeast Add to the shaker for secondary shaking culture; S6. Repeat the above steps S1-S5 until the preparation ends.

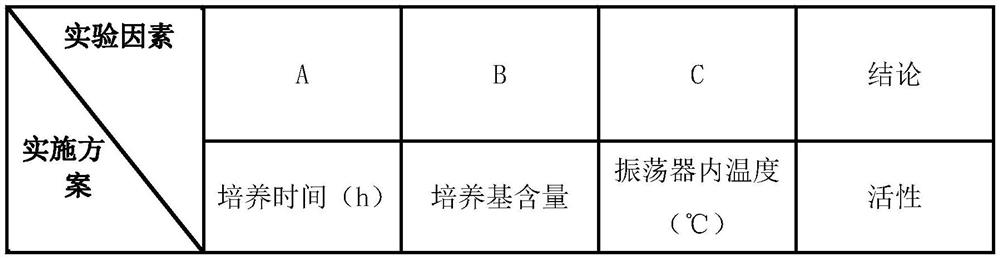

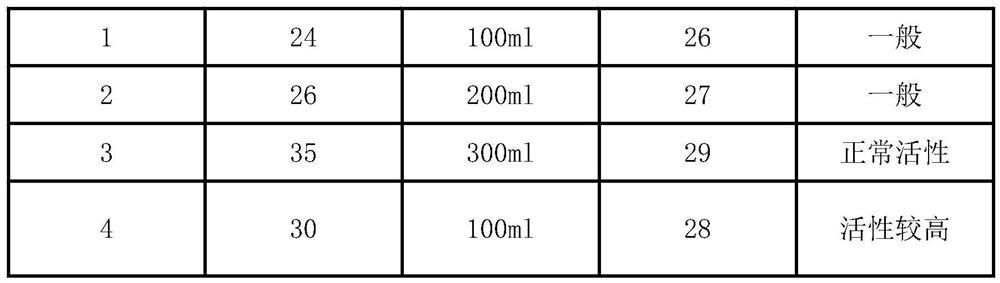

[0026] Prepare 100ml of liquid medium YPD, place YPD in a sterile environment, add bacterial powder to YPD for mixing, and the bacterial powder contains 2% glucose and 1% NaCl by mass. The yeast was placed in a shaker with a temperature of 26°C, and was continuously rotated for 3 days at a rotation speed of 180 r / min, and 3 ml of activated bacterial solution was added to the liquid medium YPD where the shaken-cultured L. , the rutheliary yeast was added to the shaker again to carry out the cultiva...

Embodiment 2

[0028] The present invention is realized through the following contents: S1. medium preparation, preparing YPD liquid medium, adding yeast, and the yeast is L. Bacteria powder; S3. Shake, put the cultured yeast into the shaker to shake; S4. Activation treatment, add the activated bacteria liquid to the yeast after shaking culture; S5. Secondary shaking, the activated yeast Add to the shaker for secondary shaking culture; S6. Repeat the above steps S1-S5 until the preparation ends.

[0029] Prepare 200ml of liquid medium YPD, place YPD in a sterile environment, add bacterial powder to YPD for mixing, and the bacterial powder contains 2% glucose and 1% NaCl by mass. The yeast was placed in a shaker with a temperature of 27°C, and was continuously rotated for 3 days at a rotation speed of 180 r / min, and 4 ml of activated bacterial solution was added to the liquid medium YPD where the shaken-cultured L. , the rutheliary yeast was added to the shaker again to carry out the cultiva...

Embodiment 3

[0031] The present invention is realized through the following contents: S1. medium preparation, preparing YPD liquid medium, adding yeast, and the yeast is L. Bacteria powder; S3. Shake, put the cultured yeast into the shaker to shake; S4. Activation treatment, add the activated bacteria liquid to the yeast after shaking culture; S5. Secondary shaking, the activated yeast Add to the shaker for secondary shaking culture; S6. Repeat the above steps S1-S5 until the preparation ends.

[0032] Prepare 300ml of liquid medium YPD, place YPD in a sterile environment, add bacterial powder to YPD for mixing, the bacterial powder contains 2% glucose and 1% NaCl by mass. The yeast was placed in a shaker with a temperature of 29°C, and was continuously rotated for 3 days at a rotation speed of 180 r / min, and 5 ml of activated bacterial solution was added to the liquid medium YPD where the shaken-cultured L. , the rutheliary yeast was added to the shaker again to carry out the cultivation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com