Novel pipe curtain-box culvert integrated tunnel structure and construction method

A pipe curtain and box culvert technology, applied in infrastructure engineering, tunnels, tunnel linings, etc., can solve the problems of not meeting the requirements of large traffic flow, the effect of the pipe curtain controlling the environment is small, and the pipe curtain cannot be recycled, and achieve the force transmission mode Conciseness, high level of mechanization, and the effect of controlling environmental influences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] In practical engineering applications, in order to form the above-mentioned pipe curtain-box culvert integrated tunnel structure, based on the construction method of the present invention, the construction method of the embodiment is further given, including the following steps:

[0058] (1) Firstly, the "originating shaft" and "receiving shaft" need to be constructed on both sides of the crossing area.

[0059] (2) After the working well is completed, the working platform is set up first, and the soil needs to be reinforced before the rectangular steel pipe curtain is formally jacked. Soil reinforcement adopts horizontal grouting to inject special modifier into the crossing soil layer.

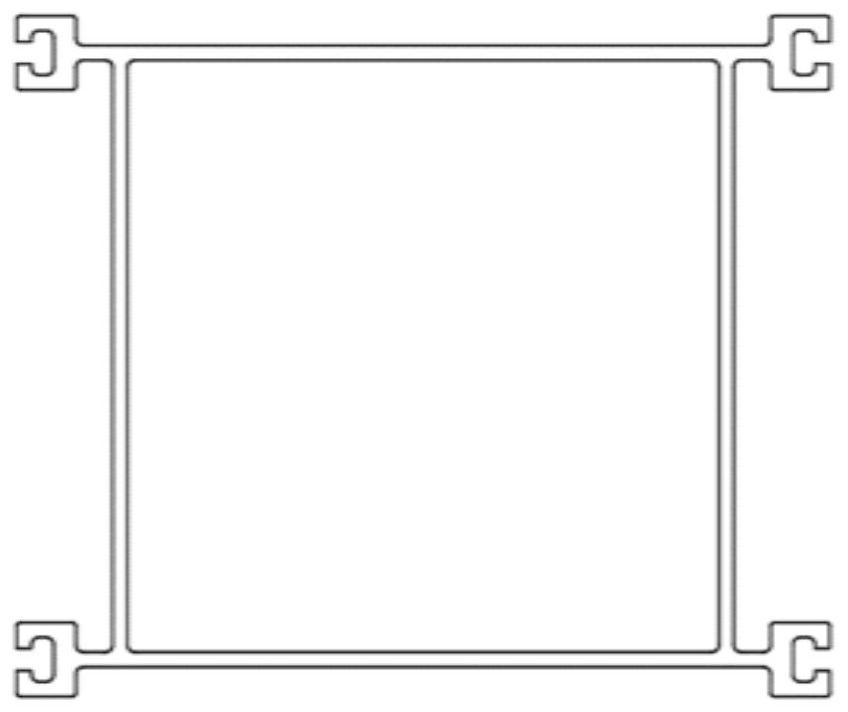

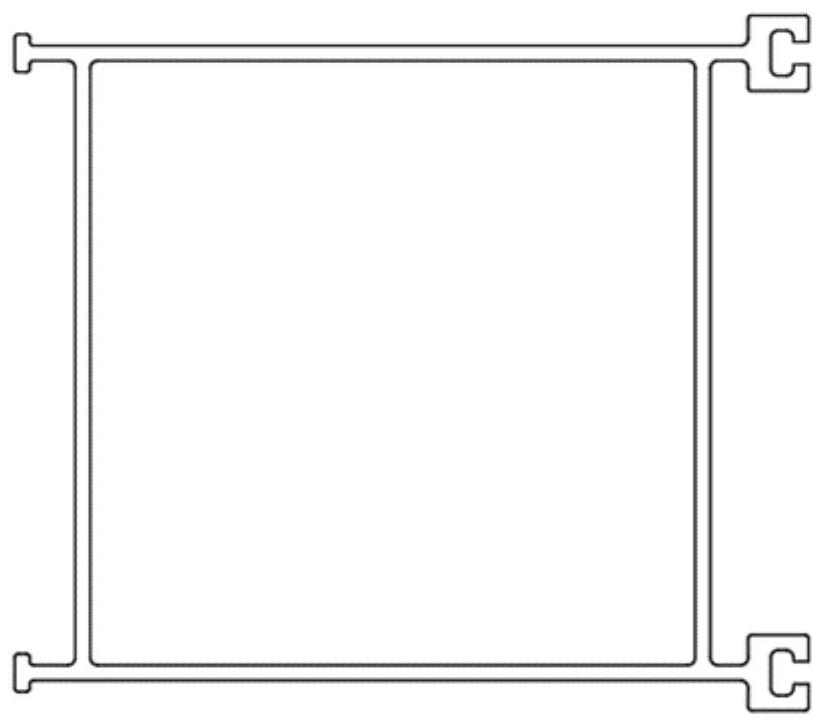

[0060] (3) The overall entry sequence of the steel pipe curtain is to first construct the upper row of pipe curtains, then to construct the side wall pipe curtains, and finally to construct the lower row of pipe curtains to form an overall structure.

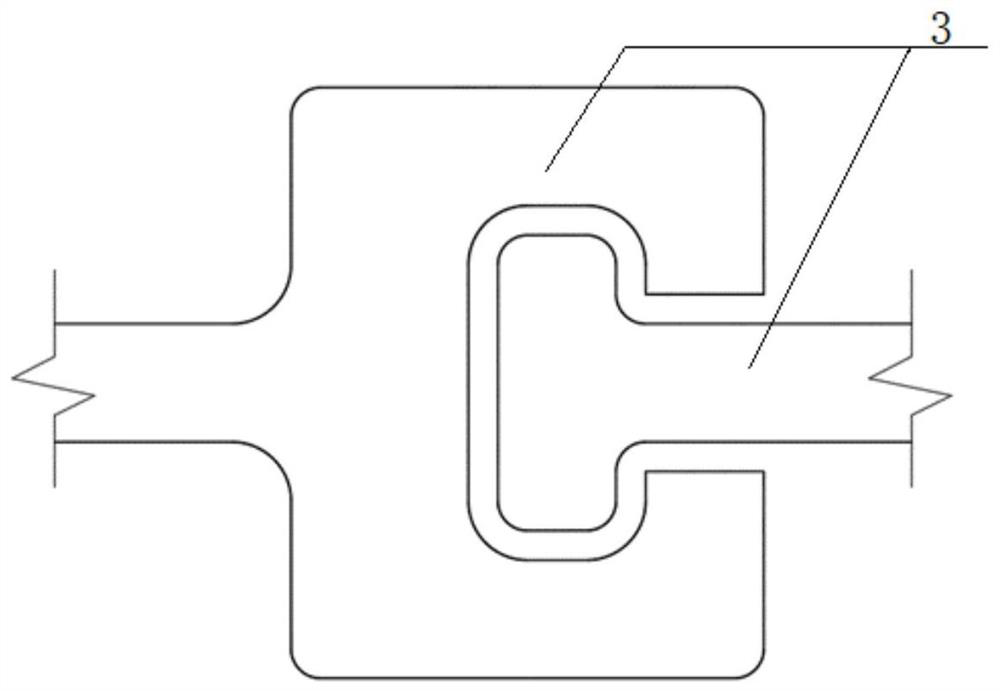

[0061] (4) Before the pipe curta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com