Gas-driven guided missile swing nozzle

A technology for nozzles and missiles, which is applied in the direction of machines/engines, jet propulsion devices, rocket engine devices, etc. It can solve the problems of complex mechanical structure of servo motors, difficulties in mass production, and high power requirements, and achieve simple and effective control methods. The effect of reducing production difficulty and reducing processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

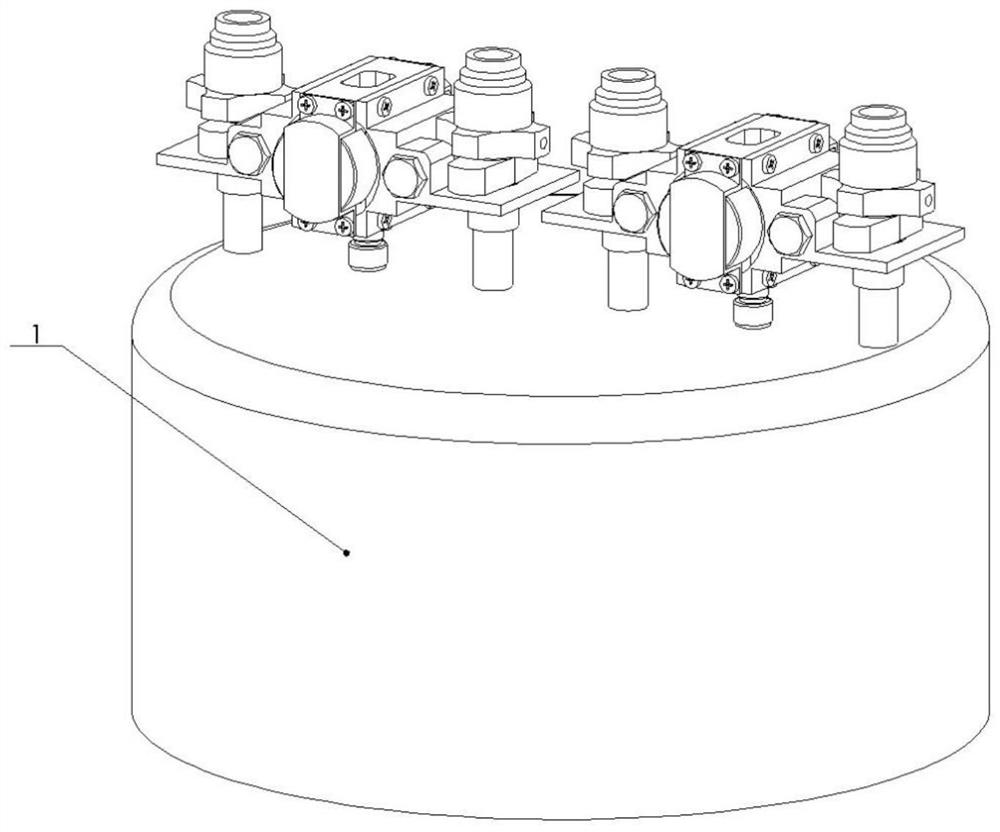

[0039] Please refer to figure 1 , which exemplarily shows a structural schematic diagram of a gas-driven missile swing nozzle provided by an embodiment of the present application.

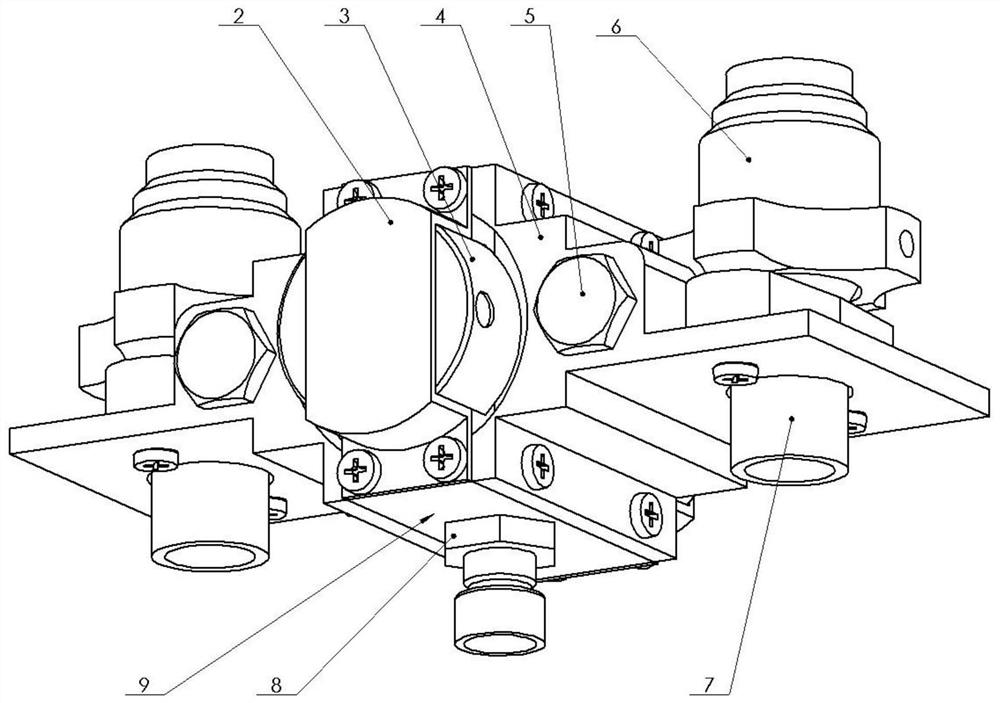

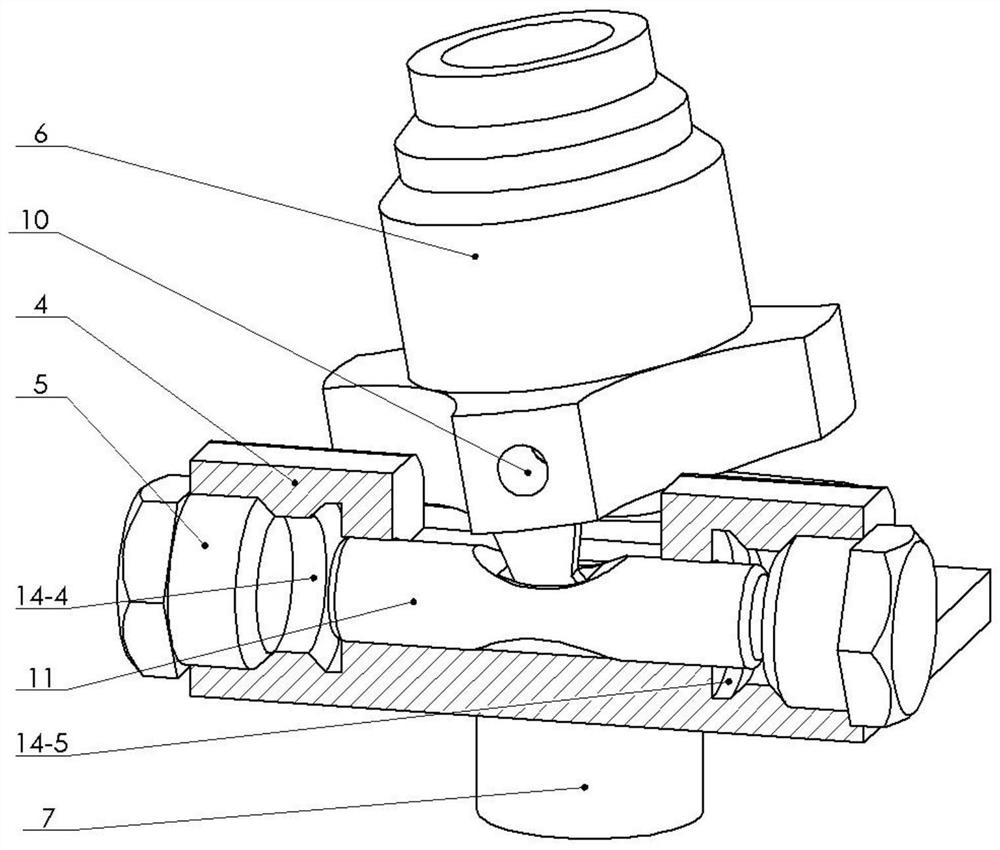

[0040] The gas-driven missile oscillating nozzle provided in the embodiment of the present application includes a combustion chamber 1 and two single-axis oscillating dual nozzle assemblies arranged side by side and symmetrically on the same end face of the combustion chamber 1 . The single-axis swing double nozzle assembly is connected to the combustion chamber 1 through the pipe group.

[0041] The components of the two single-axis swing double nozzle assemblies are the same, and the structures are symmetrical. The single-axis swing double nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com