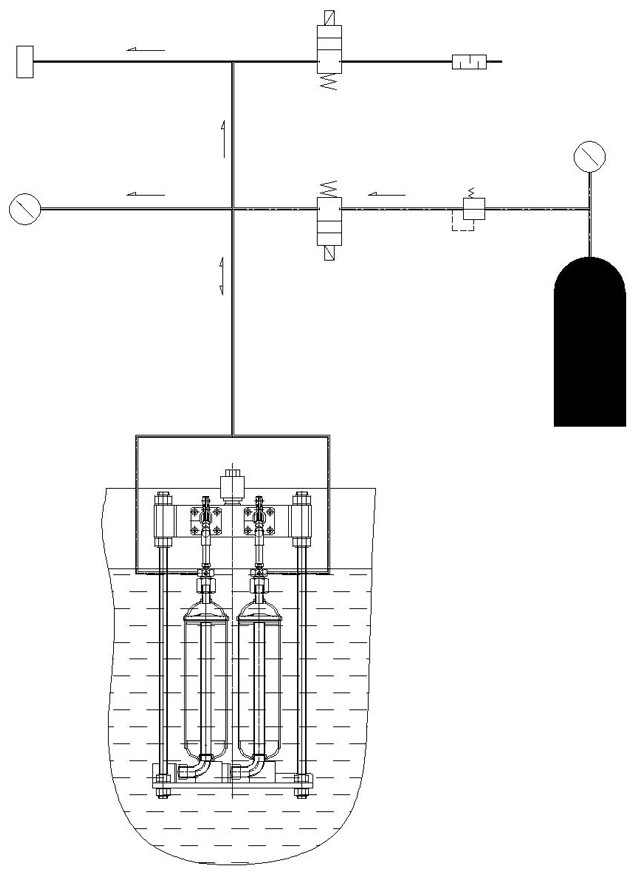

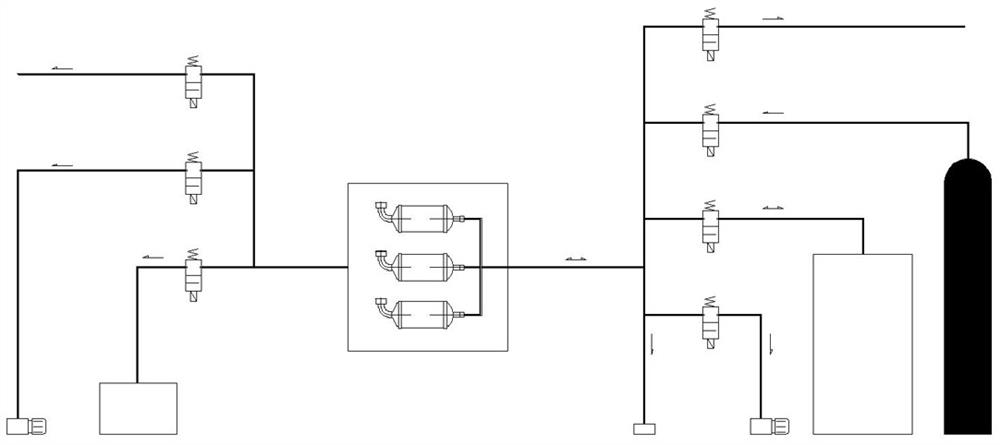

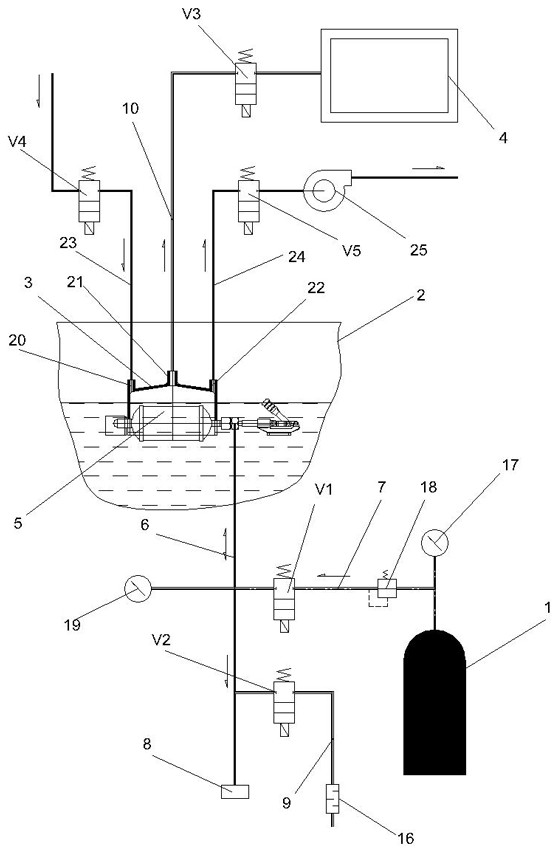

Gas-collecting hood method leakage detection system for liquid accumulator leakage detection and leakage detection method thereof

A technology of leak detection and liquid reservoir, applied in the direction of detecting the appearance of fluid at the leak point, testing of machine/structural components, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of increasing the surface resistance of the liquid reservoir Rust workload and work difficulty, increased labor and management costs, low detection accuracy and other issues, to achieve the effect of eliminating misjudgment due to human factors, equipment factors, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0061] Liquid receiver leak detection (gas-collecting hood helium detection): change the test gas to helium (that is, use a helium cylinder for the inflatable bottle), replace the hydrogen leak detector with a helium mass spectrometer leak detector, the same principle can form a set Gas mask method helium detection system. NOTE: Try to evacuate both the hood "detection space" and the leak detector mass spectrometer chamber simultaneously.

Embodiment 3

[0063] Liquid receiver leak detection (halogen detection by gas-collecting hood method): change the test gas to halogen gas (that is, the gas cylinder uses a halogen gas cylinder), and replace the hydrogen leak detector with a halogen leak detector. The same principle can form a gas collection Cover method halogen detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com