Horizontal test device and method for Seebeck coefficient and conductivity of thermoelectric material

A Seebeck coefficient and testing equipment technology, which is applied in the direction of material thermal development, measuring resistance/reactance/impedance, measuring devices, etc., can solve the problems of prone to error, failure to simultaneously test the conductivity of thermoelectric materials, and inconvenient operation , to achieve the effect of simple test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

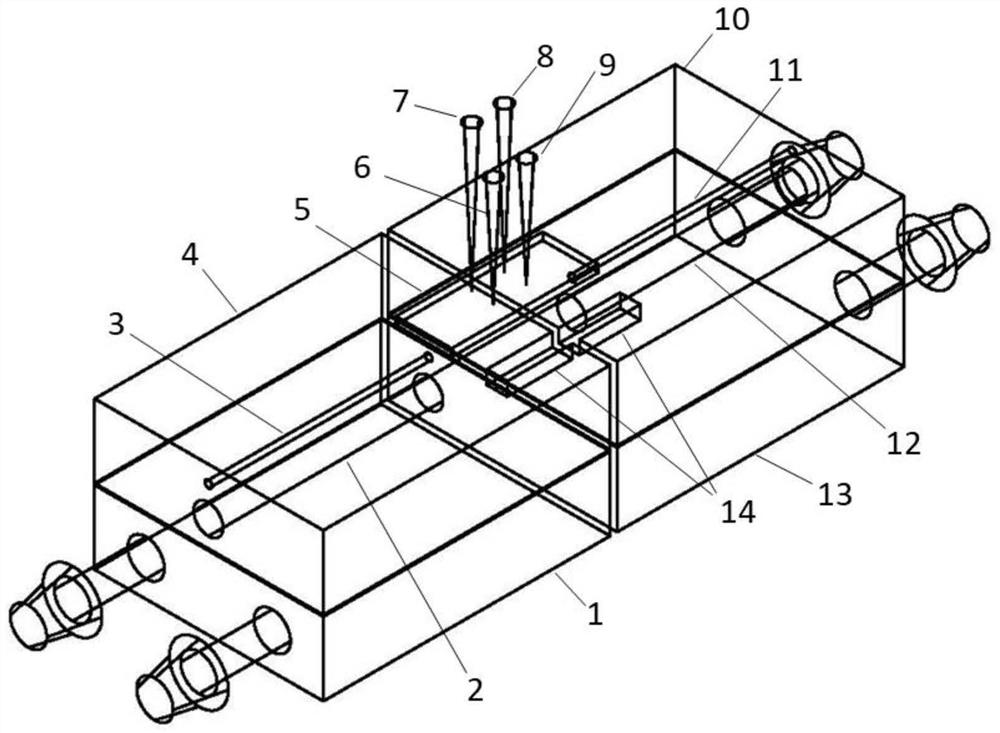

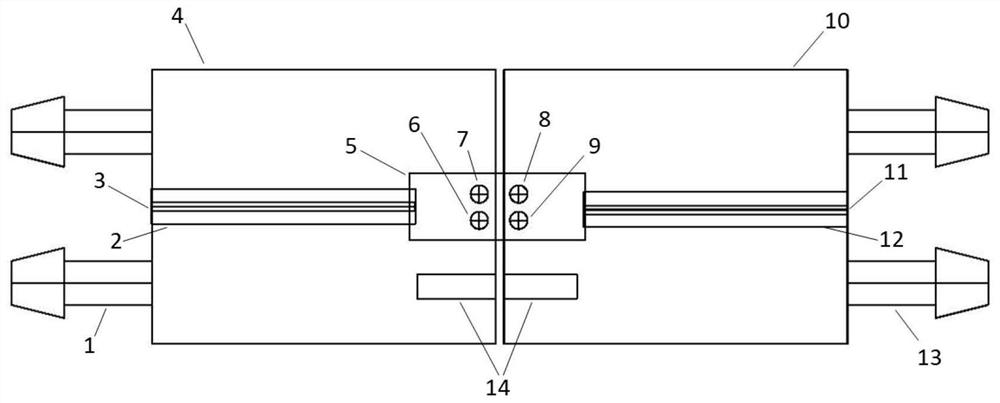

[0104] like Figure 1-4 The horizontal test equipment for the Seebeck coefficient of thermoelectric materials is shown, which is suitable for testing thermoelectric thin film materials. The test equipment includes a first test unit and a second test unit connected in parallel.

[0105] The first test unit includes a first cooling system 1, a first heating rod 2, a first temperature sensor 3, a first heating block 4, a first temperature measuring probe 6, a first voltage testing probe 7, and a second voltage testing probe Probe 8.

[0106] The second testing unit includes a second cooling system 13 , a second heating rod 12 , a second temperature sensor 11 , a second heating block 10 , a second temperature measuring probe 9 , and a second voltage testing probe 8 . The first heating block 4 and the second heating block 10 are horizontally placed side by side, and the first heating block 4 and the second heating block 10 jointly carry the film sample 5 to be tested, that is, th...

Embodiment 2

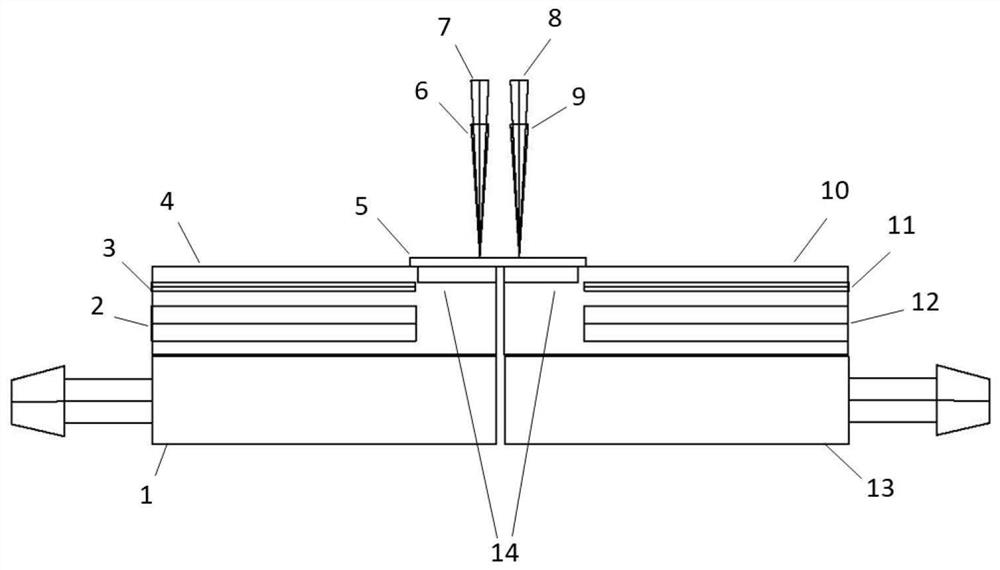

[0115] like Figure 9-11 As shown in the testing equipment for simultaneously testing Seebeck coefficient and electrical conductivity, in addition to the components of the equipment in Embodiment 1, the first testing unit also includes the conductive needle 7'a of the first current testing probe, and the second testing unit It also includes a conductive needle body 8'a of the second current test probe.

[0116] Figure 9 A three-dimensional schematic diagram of the four-probe method for testing the conductivity of thin film materials, Figure 10 Three-dimensional schematic diagram for testing the conductivity of bulk materials by the four-probe method. Figure 9 Among them, the conductive needle body 7'a of the first current test probe, the first voltage test probe 7, the second voltage test probe 8, and the conductive needle body 8'a of the second current test probe are sequentially arranged in a line Set on a straight line passing through the geometric center of the sampl...

Embodiment 3

[0121] Example 3: Polycrystalline N-type Bi 2 Te 3 Thin film Seebeck coefficient test

[0122] Using the testing equipment that embodiment 1 provides, to polycrystalline N-type Bi 2 Te 3 The Seebeck coefficient of the film is tested:

[0123] A1) Polycrystalline N-type Bi 2 Te 3 The film is placed on the first heating block and the second heating block, and the distance between the first heating block and the second heating block is adjusted according to the size of the film sample to ensure that the sample is completely placed on the surface of the heating block;

[0124] A2) The first temperature measurement probe and the first voltage test probe are in contact with one end of the film sample, and the distance between the probes is less than 1mm; the second temperature measurement probe and the second voltage test probe are connected to the other end of the film sample One end is in contact and the distance between the probes is less than 1mm.

[0125] A3) Before the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com