Punching machine tool for deburring

A deburring and punching technology, which is applied to machine tools, grinders, piercing tools, etc., which are suitable for grinding the edge of workpieces, and can solve problems such as inaccuracy, time-consuming and laborious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

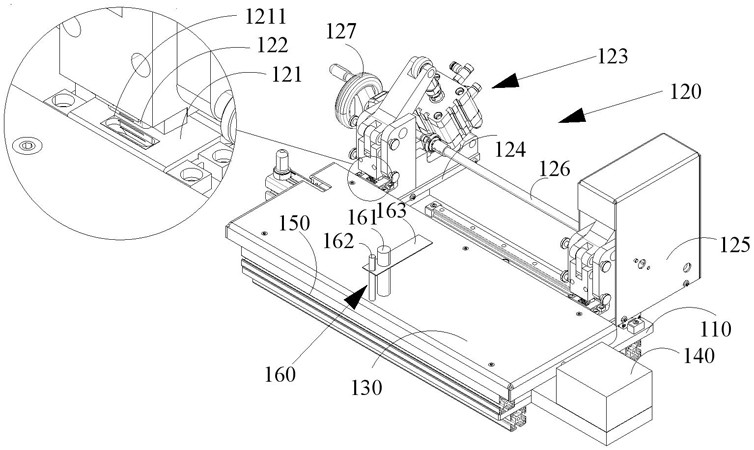

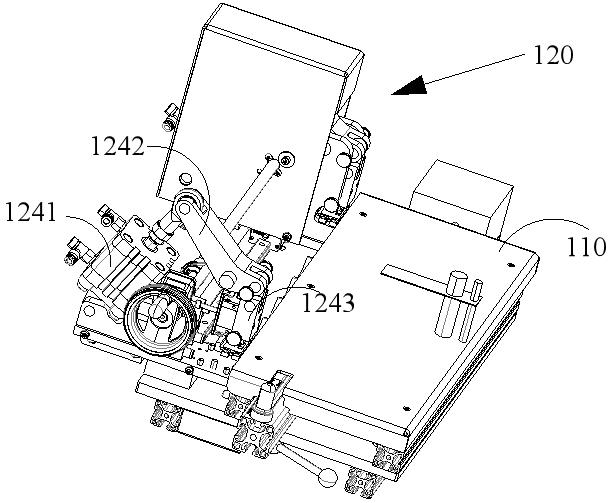

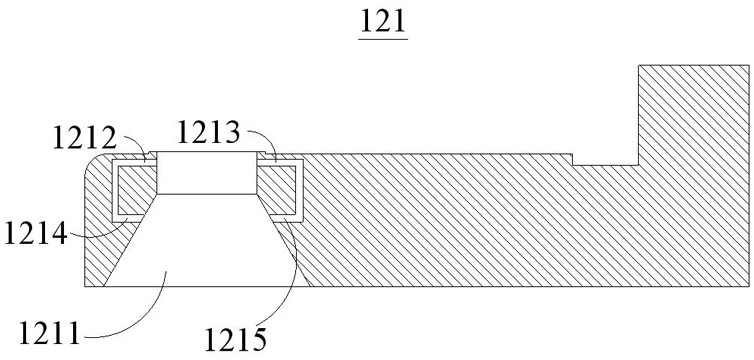

[0061] see Figure 1-Figure 6 , the present embodiment 1 provides a punching machine tool for deburring, including: a working platform 110, a punching mechanism 120, a mobile platform 130, a screw motor 140 and a slide rail 150; the slide rail 150 is fixedly arranged on the on the working platform 110; the mobile platform 130 is slidably connected on the slide rail 150; the screw of the screw motor 140 is screwed to the side wall of the mobile platform 130, and is suitable for driving the The mobile platform 130 moves on the slide rail 150; the punching mechanism 120 is fixedly arranged on the working platform 110, and the punching mechanism 120 includes a die 121, a driving assembly 123 and a punch 122, and the punching mechanism 120 The head 122 is suitable for clamping the die 121 under the drive of the driving assembly 123, thereby punching the sheet placed on the mobile platform 130; the upper surface of the die 121 of the punching mechanism 120 A polishing sheet 121 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com