Automatic sand mold casting device

A sand casting and automatic technology, applied in the field of sand casting, can solve the problems of waste of sand raw materials, cumbersome operation steps, affecting processing efficiency, etc., and achieve the effect of improving molding quality, high smoothing quality, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

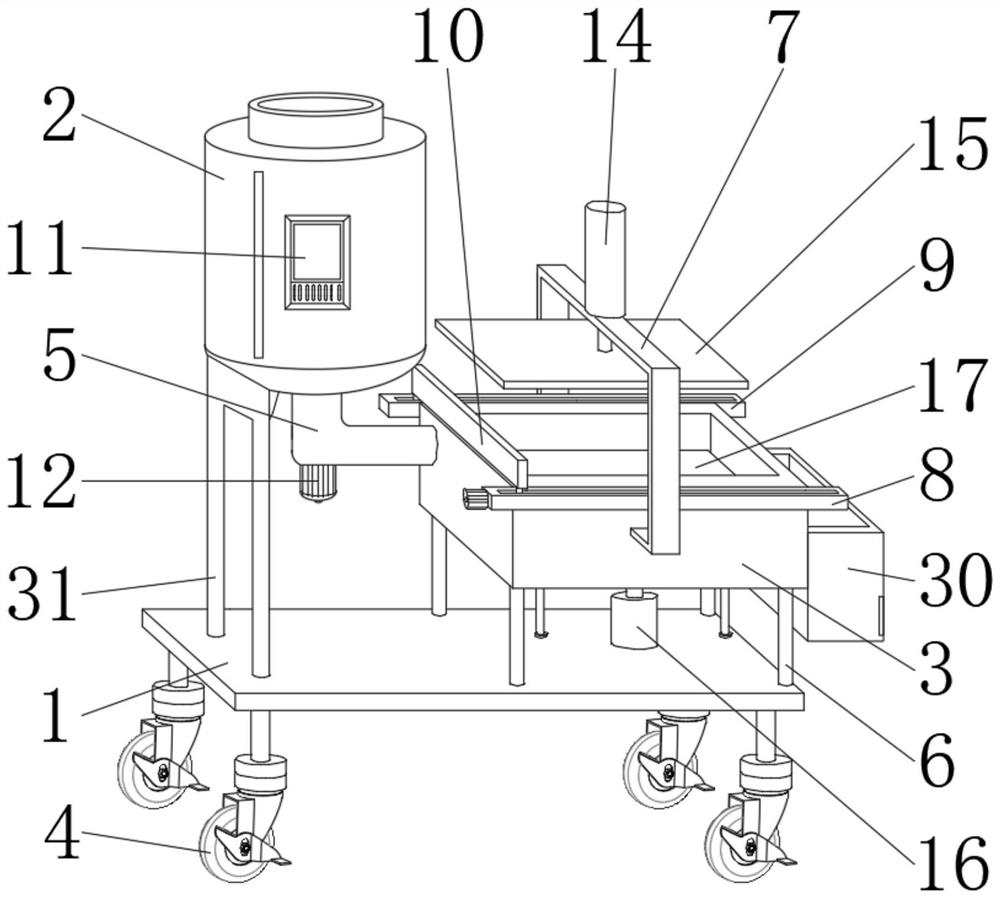

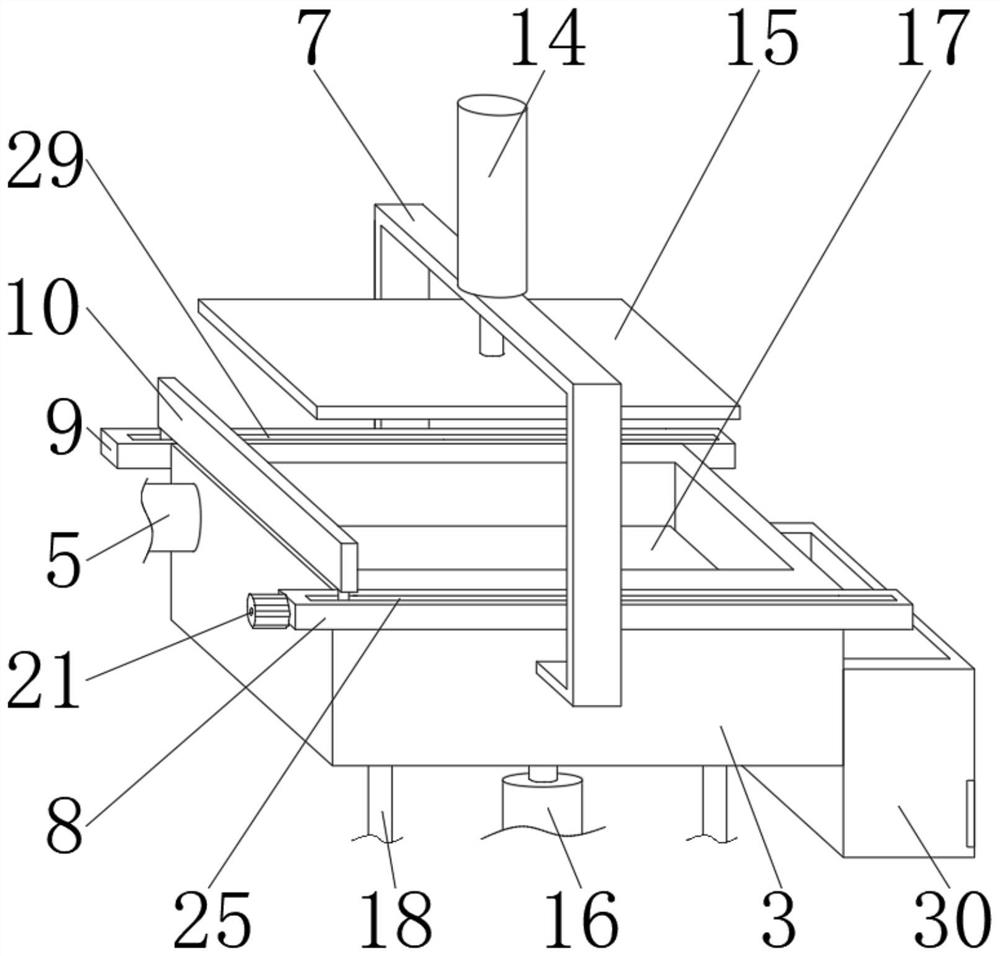

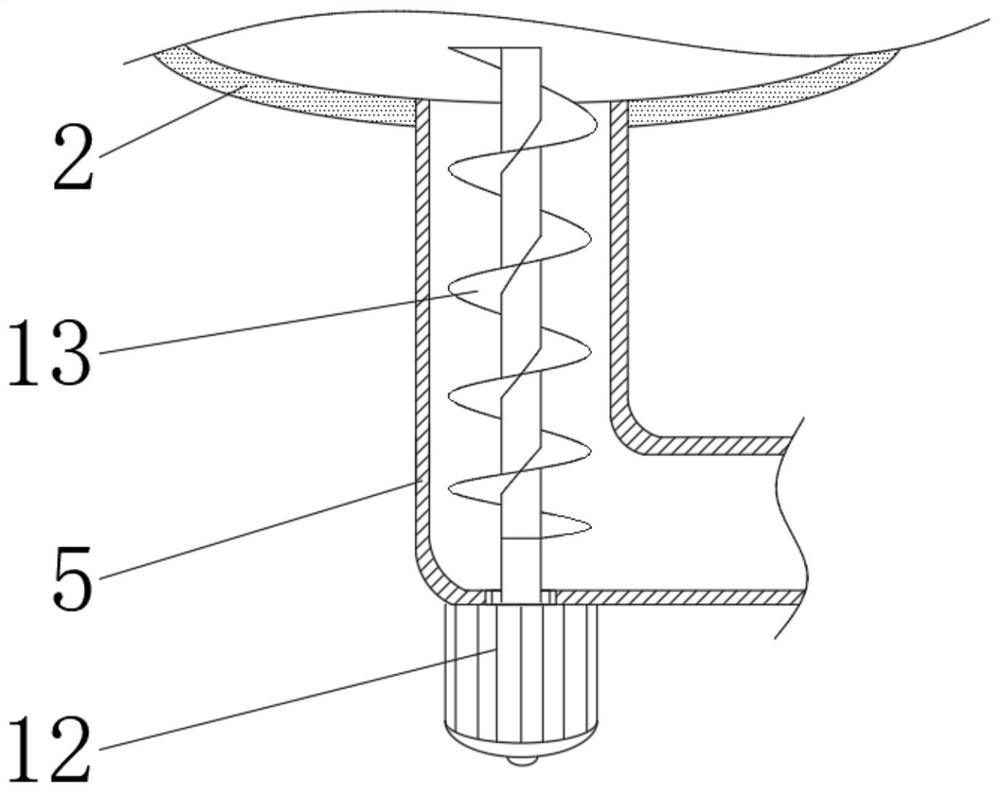

[0026] see Figure 1~5 , in an embodiment of the present invention, an automatic sand casting device includes a casting table 1, a sand storage tank 2 and a sand tank box 3, and the four corners of the bottom of the casting table 1 are respectively fixedly connected with four symmetrically arranged locking The universal wheel 4 is convenient for the displacement or positioning of the device. The sand storage tank 2 is located above the casting table 1, and the sand mold raw materials are stored in the sand storage tank 2, and the bottom of the sand storage tank 2 is connected with an L-shaped feed pipe 5, The vertical end of the L-shaped feed pipe 5 is provided with a feeding mechanism, and the upper side of the casting table 1 is fixedly connected with four vertically symmetrical pillars 6, and the four pillars 6 are far away from one end of the casting table 1 and the sand tank. The bottom of the box 3 is fixedly connected, and the end of the L-shaped material guide pipe 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com