Metal material processing system

A processing system and metal material technology, applied in the field of processing, can solve problems such as low reliability, obstruction, rough surface of parts, etc., to achieve the effect of ensuring a flat surface, simple and direct algorithm, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below with reference to the accompanying drawings and embodiments.

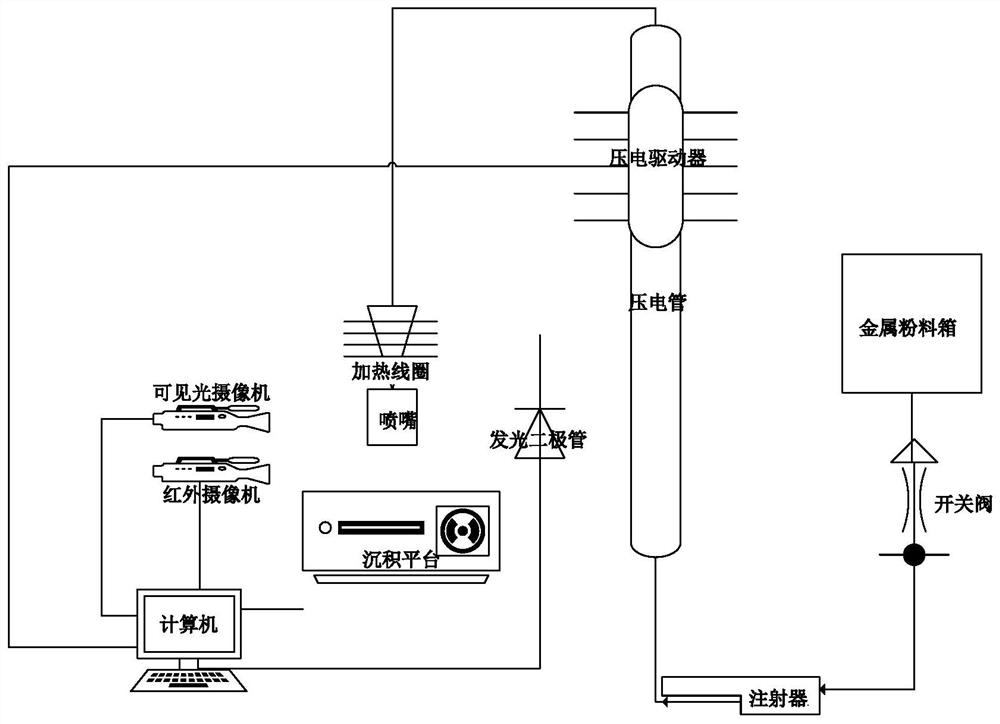

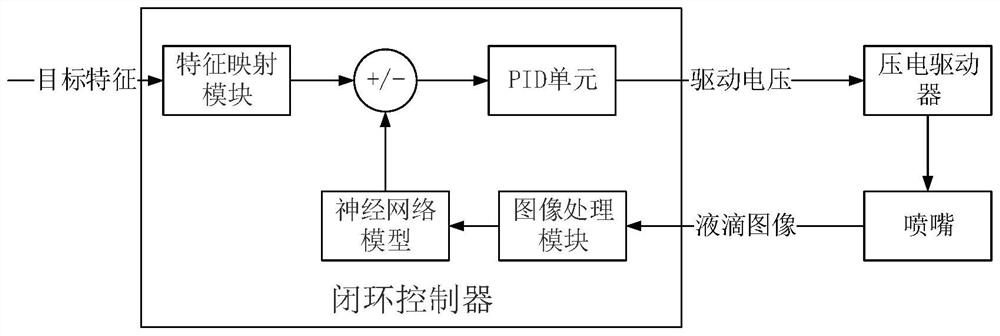

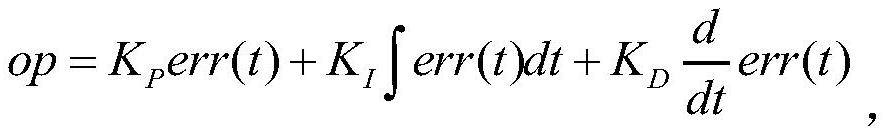

[0013] Reference to embodiments of the present invention Figure 1-2 shown.

[0014] A metal material processing system, including a visible light camera, an infrared camera, a light-emitting diode, a deposition platform, a computer, a piezoelectric driver, a nozzle, an induction heating coil, a piezoelectric tube, a syringe, a metal powder box and an on-off valve, a metal powder box Under the push of the syringe, the metal powder box enters the piezoelectric tube. By adjusting the syringe, the metal powder is pumped into the piezoelectric tube. The liquid level in the piezoelectric tube will reflect the pressure applied to the metal powder. After the metal powder box in the electric tube enters the nozzle, it forms droplets under the action of the induction heating coil, which drop to the interface on the deposition platform, and the deposition platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com