Gauze product die-cutting system and manufacturing method thereof

A mesh and die-cutting technology, used in film/sheet adhesives, metal processing, winding strips, etc. The effect of shortening the production cycle and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

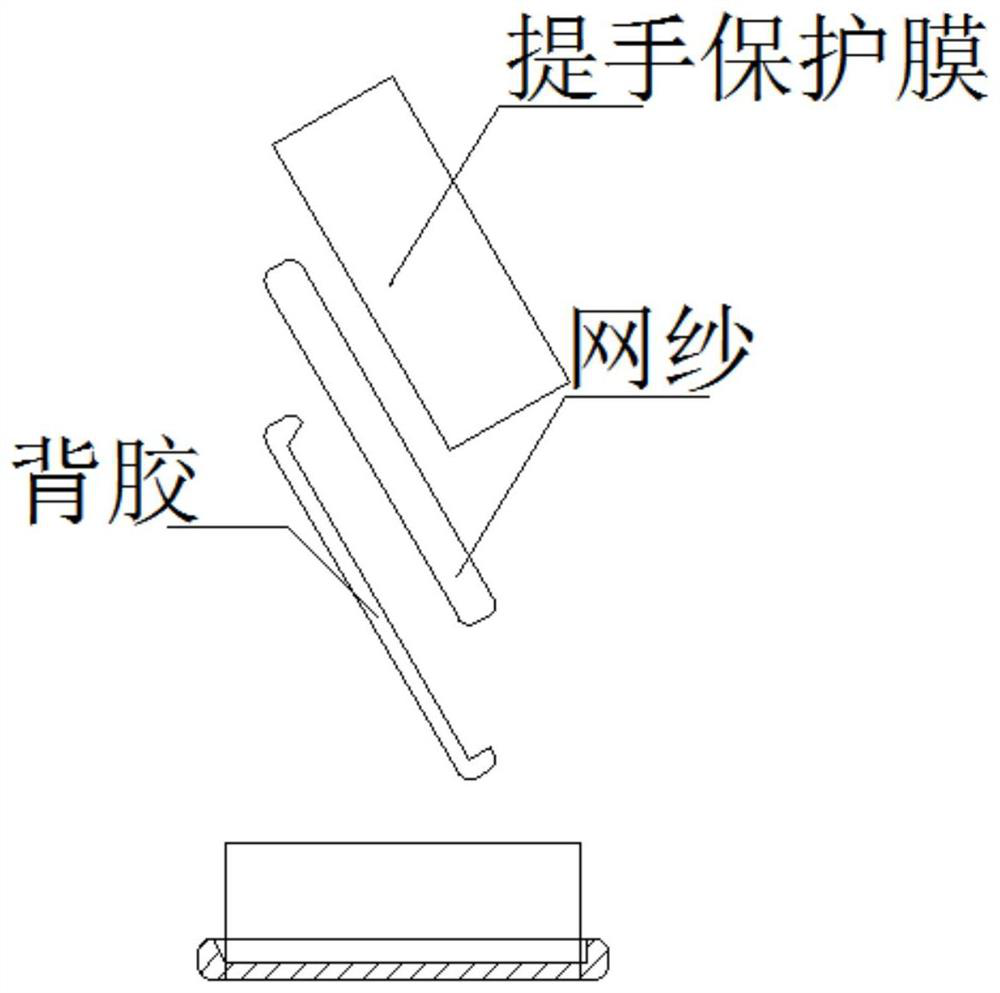

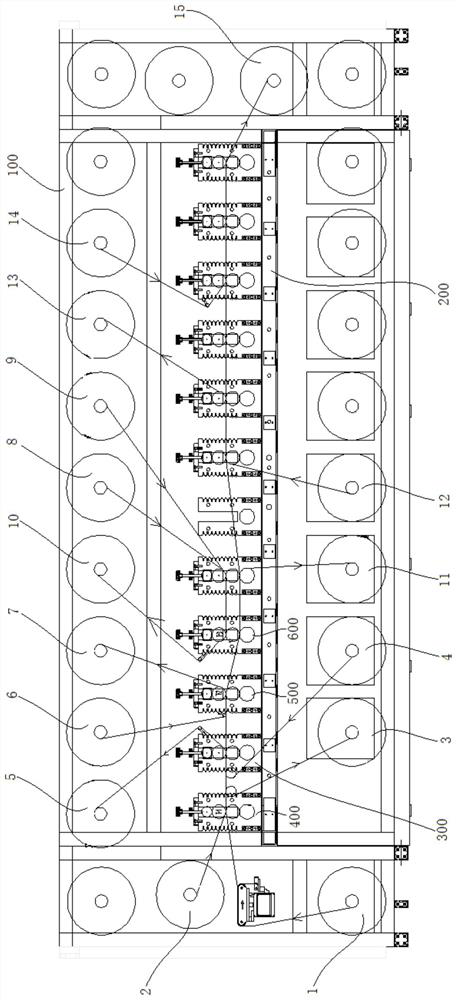

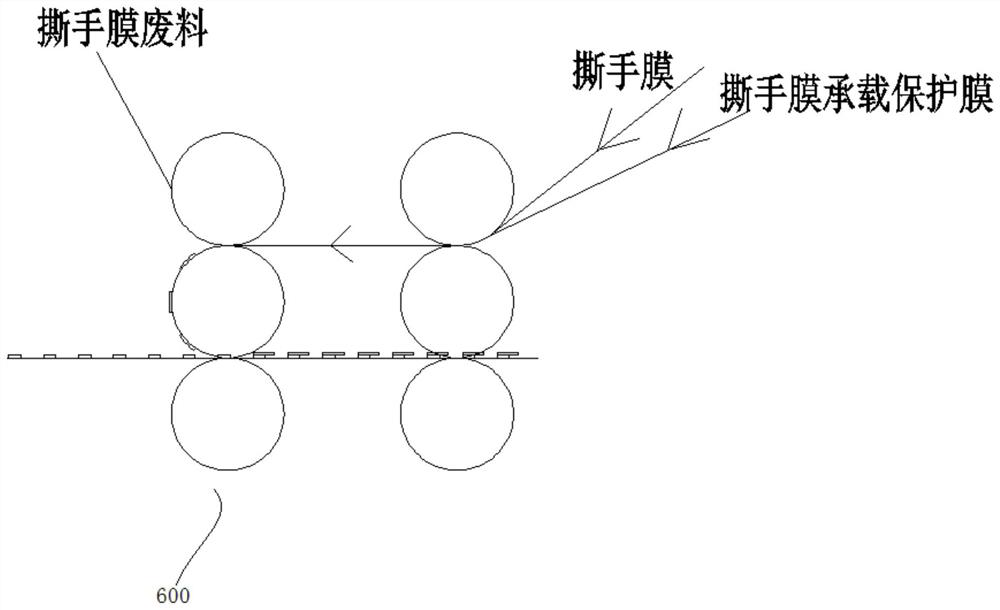

[0077] Such as figure 1 , which is a certain mesh product that needs to be processed. It is specifically used in mobile phones. It has a three-layer structure, the middle is mesh, the upper part is tearing protective film, and the lower part is adhesive (double-sided adhesive). This product is designed as a mesh One side of the yarn is partly backed with adhesive, and the handle is attached to the surface for easy assembly. At present, the method of processing and manufacturing this product is that the pre-sample is produced with a flat knife, and the defective rate of the product is high, and the semi-finished product of the mesh and adhesive and the semi-finished product of the tearing protective film need to be manually assembled and bonded with a jig. Not only does it lead to efficiency, but also the problems of high product defect rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com