Sintered graphene foam block reinforced graphene heat-conducting gasket and preparation method thereof

A technology of graphene foam and thermal pads, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve problems such as poor thermal conductivity of adhesives, affecting thermal conductivity of composite materials, and reducing thermal conductivity of composite materials , to achieve the effect of high thermal conductivity in the thickness direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

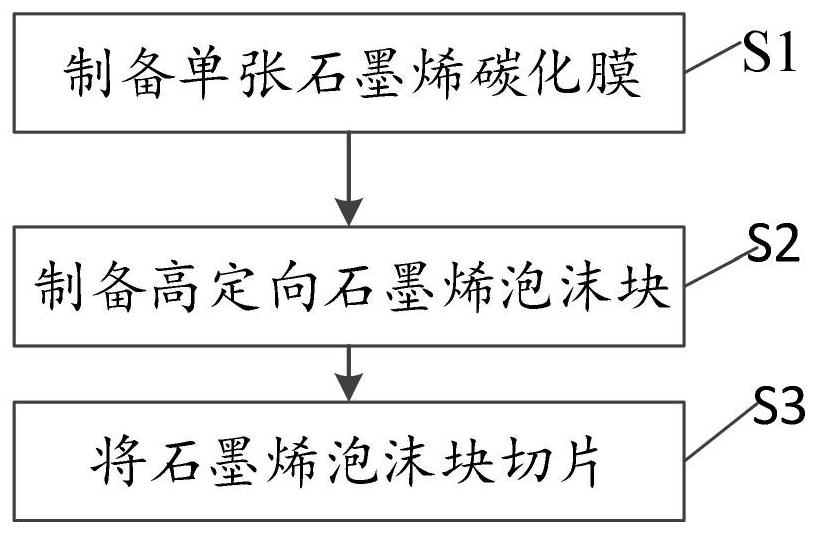

[0044] figure 1 It is a schematic diagram of the flow chart of the preparation method of the graphene thermal pad reinforced by sintered graphene foam block of the present invention, as figure 1 Shown, described preparation method comprises:

[0045] Step S1, preparing a single graphene carbide film;

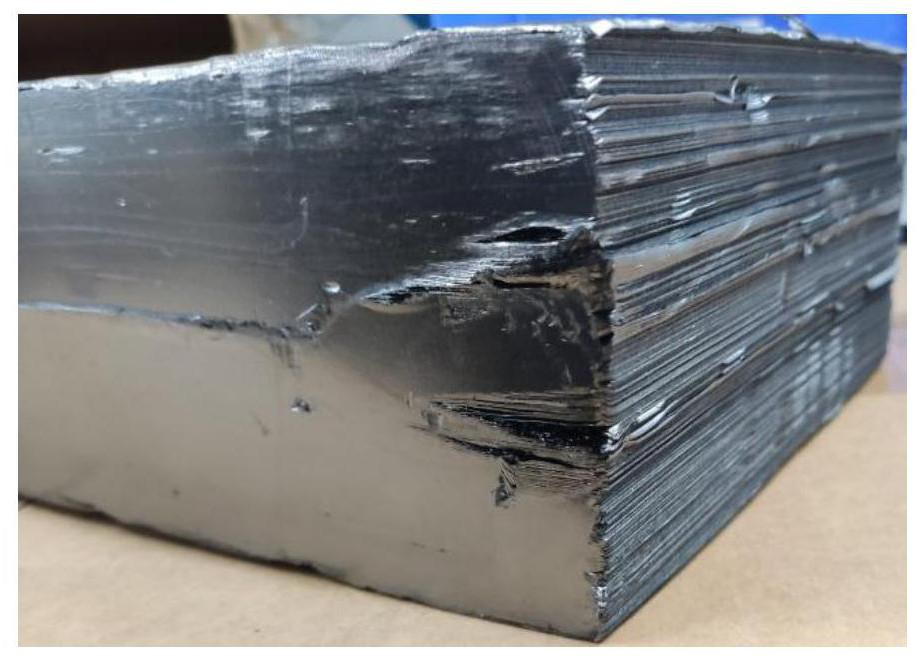

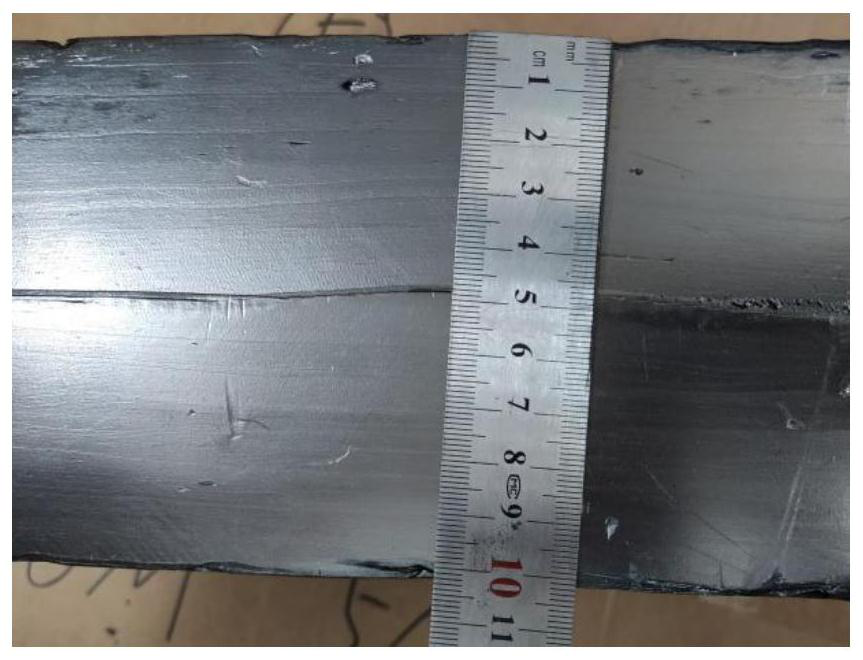

[0046] Step S2, preparing highly oriented graphene foam blocks, such as figure 2 , 3 and 5, from figure 2 and 5 It can be seen that the multiple graphene carbonized films of the graphene foam block are neatly stacked layer by layer along the horizontal direction (x-y plane) on the microstructure. From the vertical section (z direction), it presents a book-like neat structure. There is no disordered graphene carbonized film such as tilting or vertical, and the graphene foam block is a highly oriented graphene foam block, and the heat of the highly oriented graphene foam block can be efficiently conducted along the horizontal direction (x-y plane), without Due to the irreg...

Embodiment 1

[0067] A single 100 μm graphene oxide film was placed between two pieces of carbon paper, and then the whole was placed in a high-temperature furnace for high-temperature carbonization. The high-temperature carbonization temperature was 1000°C, the heating rate was 2°C / min, and the internal pressure of the high-temperature furnace was 10Pa. After high-temperature carbonization, a single 120 μm graphene carbide film was prepared. 833 graphene carbonized films are stacked into blocks, and then the stacked blocks are placed between two sheets of carbon paper, and then a graphite plate is placed on top to increase the pressure. The pressure is controlled at 5MPa, and then the whole is placed in a high-temperature furnace for high-temperature graphitization , the high-temperature graphitization temperature is 3000°C, the heating rate is 3°C / min, and the atmosphere of the high-temperature furnace is inert gas. After graphitization at high temperature, a 100 mm thick graphene foam bl...

Embodiment 2

[0069] A single 200 μm graphene oxide film was placed between two pieces of carbon paper, and then the whole was placed in a high-temperature furnace for high-temperature carbonization. The high-temperature carbonization temperature was 1000°C, the heating rate was 2°C / min, and the internal pressure of the high-temperature furnace was 10Pa. After high-temperature carbonization, a single 300 μm graphene carbide film was prepared. Stack 334 graphene carbonized films into blocks, then place the stacked blocks between two sheets of carbon paper, and then place a graphite plate on top to increase the pressure, control the pressure to 5MPa, and then place the whole in a high-temperature furnace for high-temperature graphitization , the high-temperature graphitization temperature is 3000°C, the heating rate is 3°C / min, and the atmosphere of the high-temperature furnace is inert gas. After graphitization at high temperature, a 100 mm thick graphene foam block is prepared. The obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com