A pneumatic pipeline conveyor

A technology of pneumatic pipelines and conveyors, which is applied in the direction of conveyors, conveying bulk materials, mixers, etc., can solve the problems of changing the conveying position, which is laborious and laborious, and cannot be guaranteed, so as to save manpower, use and maintain low costs, and save electricity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

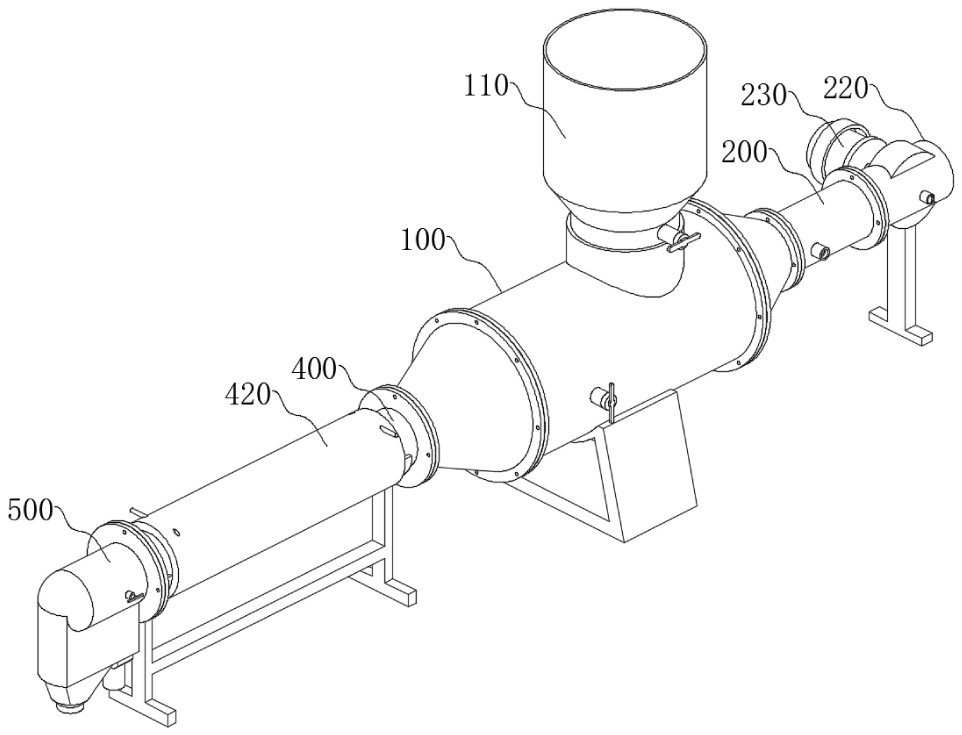

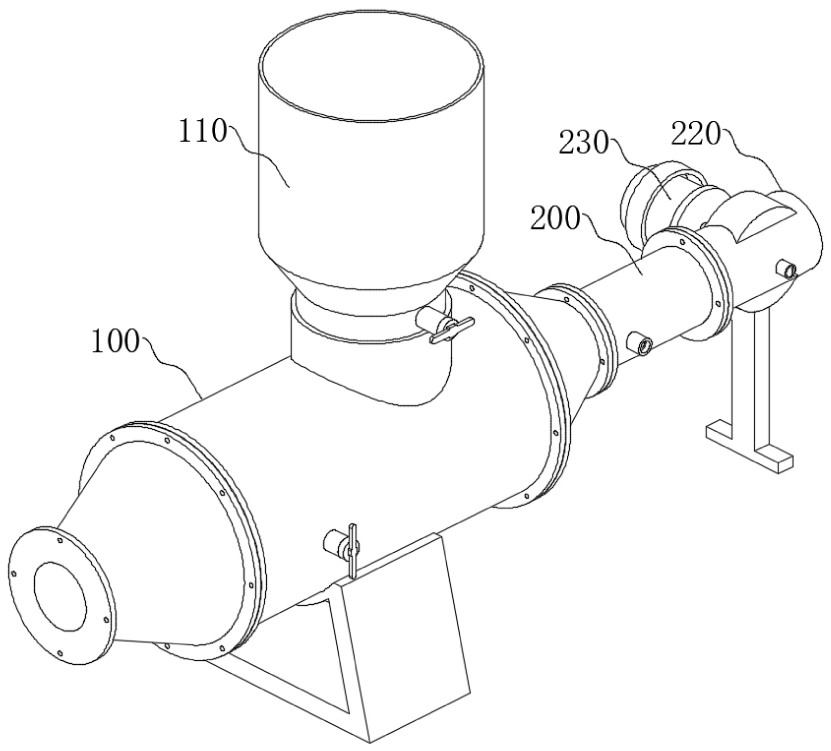

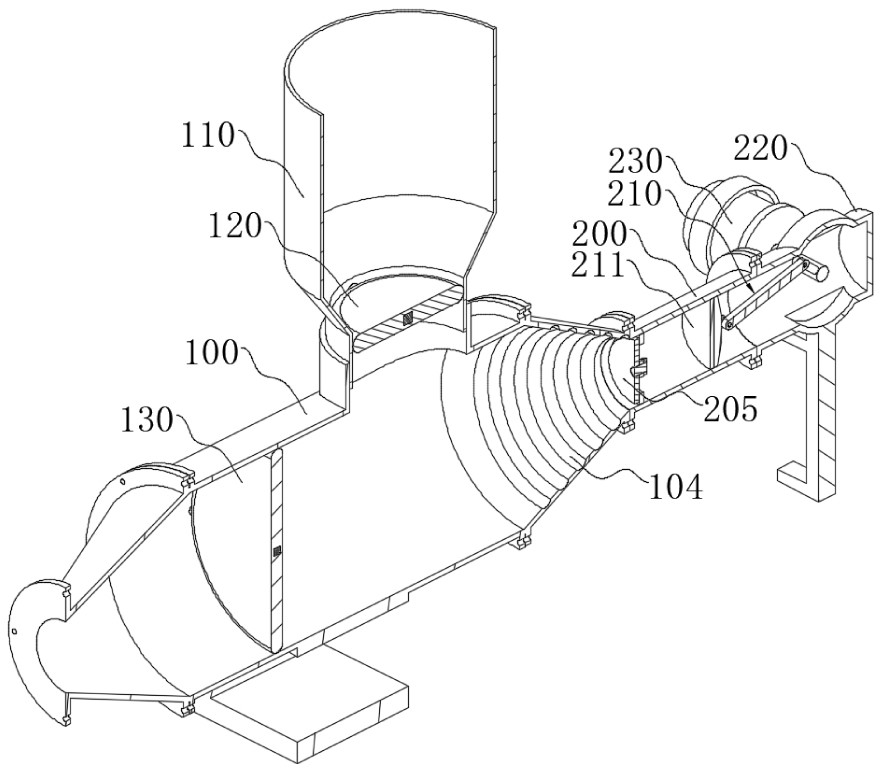

[0049] see Figure 1-Figure 17 As shown, the present invention provides a pneumatic pipeline conveyor, which includes a mixing tube 100 that can mix different types of particles and a pneumatic tube 200 that is used to inject air into the interior of the mixing tube 100, that is, using air flow to mix different types of particles. Different types of particles are mixed and then transported. The mixing pipe 100 is provided with an injection cylinder 110 near the top of its rear end, which is used to inject chemical particles such as polypropylene, PET, ABS, PVC, etc., so as to realize mechanized and automatic material delivery, which can reduce labor intensity and save manpower. And during the conveying process, the technological operations of mixing, drying and screening can be carried out at the same time. The bottom of the injection cylinder 110 is radially rotatably connected with a cylinder valve block 120 for partially blocking the injection cylinder 110 to prevent the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com