Preparation method of polyester-cotton blended weft-wise double-wrapped elastic fabric

A polyester-cotton blended, weft-oriented technology is applied in the field of preparation of polyester-cotton blended weft-direction double-wrap elastic fabrics, which can solve problems such as poor elastic properties, and achieve the effects of promoting density and fastness, ensuring three-proof effects, and wearing comfortably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

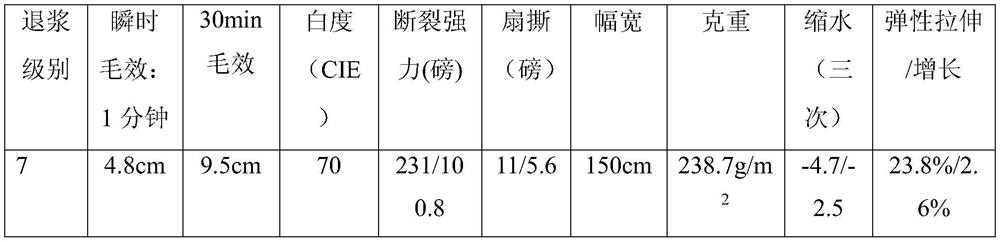

Embodiment 1

[0058] The preparation method of polyester-cotton blended weft two-pack elastic fabric of the present invention specifically comprises the following steps:

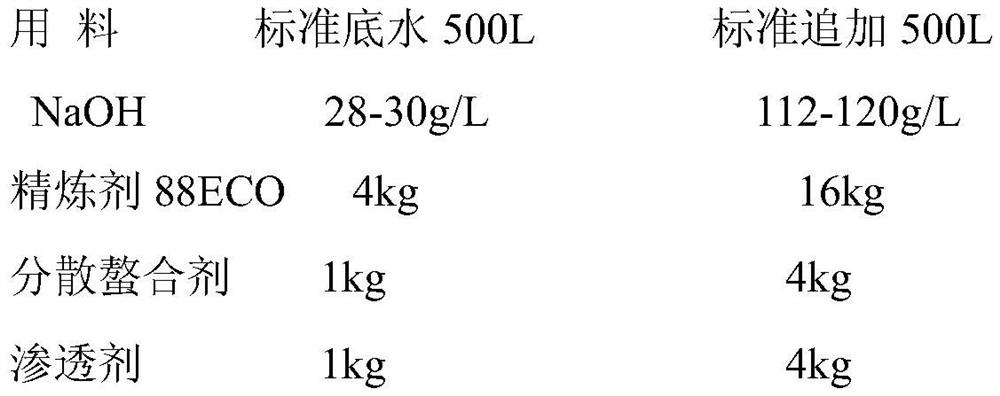

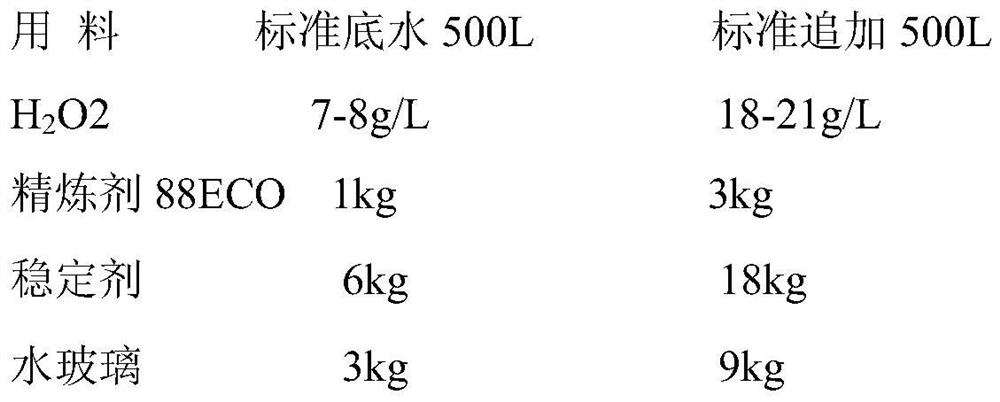

[0059] (1) Joint treatment of deboiling and bleaching

[0060] A. The vehicle speed is 65 m / min, and the track is adjusted for 45 minutes in the front section and 40 minutes in the back section.

[0061] B. Wash in hot water at 85-90°C in the first 3 compartments of the washing tank, with a water rolling force of 0.3Mpa, and wash in hot water at 75-80 °C in the fourth compartment of the washing tank. Pad car pressure 0.2-0.25Mpa, tension 0.25-0.35Mpa, 4# pad car open spray. Heat the alkaline water.

[0062] C. The first high feeding liquid rolling material, pressure south 0Mpa., north 0Mpa., working fluid temperature 50-60 ℃, trough liquid level 0.4m,

[0063]

[0064] Track temperature 101-102°C. The incoming steam pressure is 0.06-0.08Mpa. The steaming time is 45 minutes, and the liquid level is 10-15cm.

[0065...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com