Ocean thermoelectric power generation cold seawater gradient utilization system

A technology for thermoelectric power generation and cold sea water, which is applied in the fields of ocean energy power generation, machinery/engine, steam engine installation, etc. It can solve the problems of low utilization rate, large investment, and no engineering application, so as to reduce the quantity and size, and increase the utilization rate. efficiency, reducing the effect of engineering construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

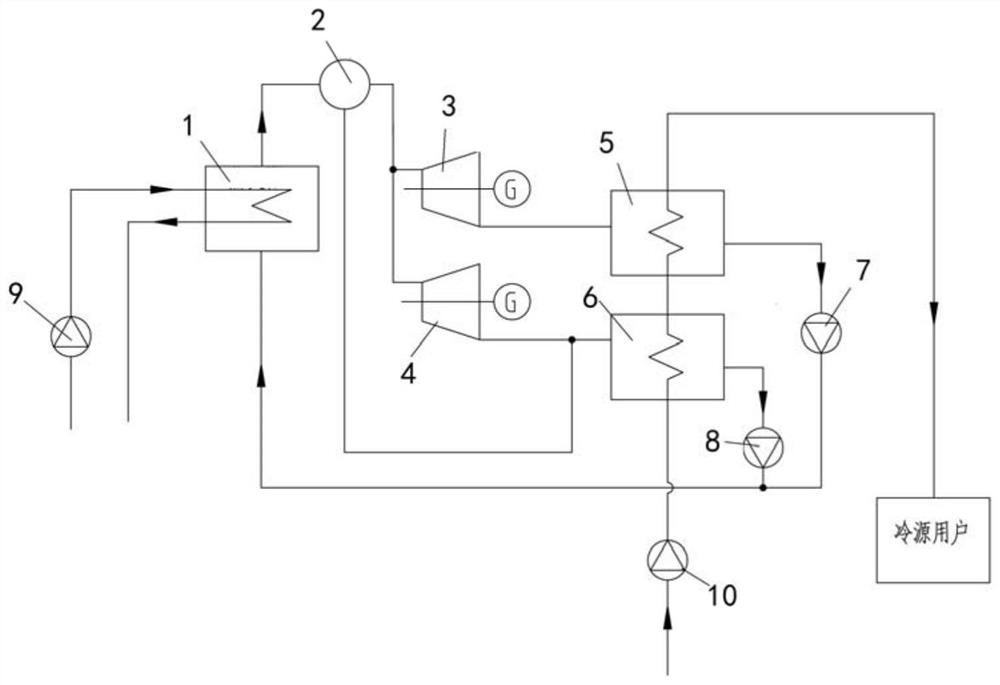

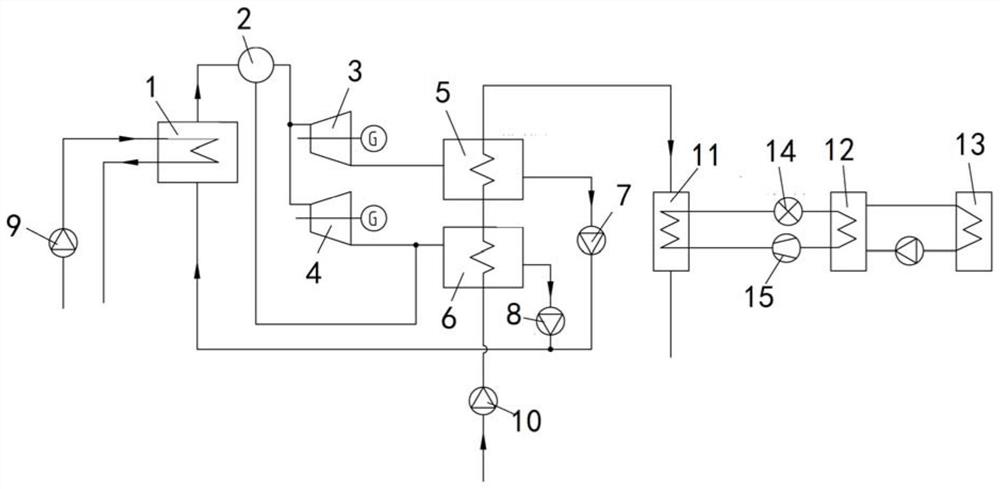

[0021] Such as figure 1 As shown, the ocean temperature difference power generation cold seawater cascade utilization system of the present invention includes steamer 1, separator 2, 1# expander 3, 2# expander 4, 1# condenser 5, 2# condenser 6, 1# Pump 7, 2# pump 8, hot sea water pump 9, cold sea water pump 10, etc.

[0022] The circulating working medium (preferably ammonia) in the utilization system exchanges heat with ocean surface seawater in steamer 1 and evaporates into steam, and the steam passes through separator 2 to separate the liquid working medium, and the remaining dry working medium enters the subsequent 1# expander 3 and 2# expander 4 convert steam thermal energy into mechanical energy in 1# expander 3 and 2# expander 4 to drive a generator to generate electricity. The steam that has done work enters the corresponding condensers (1# co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap