Temperature drop type anti-explosion early-warning hydraulic oil cylinder

A hydraulic oil cylinder and temperature drop technology, applied in the field of hydraulic oil cylinders, can solve the problems of high cylinder explosion risk, cylinder explosion, difficult staff and other problems, and achieve the effect of ensuring cooling effect, preventing cylinder explosion and improving cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

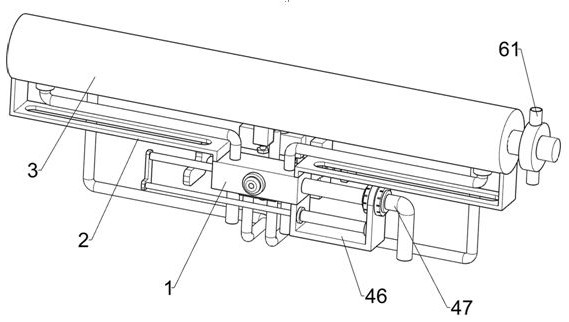

[0040]Temperature drop explosion-proof early warning hydraulic cylinder, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, it includes a liquid guide frame 1, a support plate frame 2, a hydraulic cylinder 3, a hydraulic drive part 4, a pressure relief part 5 and a double-pipe cooling part 6, and a pair of support plate frames 2 are fixedly connected to the top of the liquid guide frame 1. A hydraulic cylinder 3 is fixedly connected between the two support plates 2, and a hydraulic drive part 4 is provided on the liquid guide frame 1, and the hydraulic drive part 4 is used to drive the hydraulic oil to flow in the hydraulic cylinder 3, and the hydraulic cylinder 3 is provided with a drain The pressure component 5 and the pressure relief component 5 are used to relieve pressure when the pressure in the hydraulic cylinder 3 is too large. The hydraulic drive c...

Embodiment 2

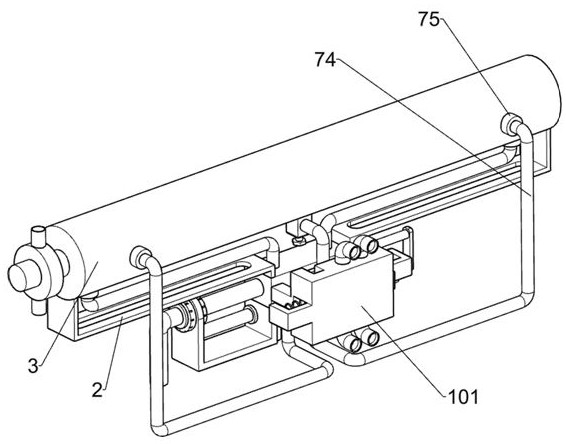

[0048] On the basis of Example 1, such as Figure 13 Shown, also comprise explosion-proof component 7, and explosion-proof component 7 is located at piston plate 45 inner tops, and explosion-proof component 7 is used for preventing explosion cylinder phenomenon from taking place, and explosion-proof component 7 includes induction rod 71, movable rod 72, back-moving spring 73, return The liquid pipe 74 and the solenoid valve 75, the upper and lower parts of the piston plate 45 are fixedly connected with a sensing rod 71, and the sensing rod 71 is used to sense pressure information, and a pair of movable rods 72 are slidably connected to the upper and lower parts of the piston plate 45. , the adjacent movable rod 72 is located on the left and right sides of the sensing rod 71, and a reset spring 73 is connected between the movable rod 72 and the sensing rod 71. Frame 1 is connected, and the liquid return pipe 74 is connected to the solenoid valve 75 by welding on the side close ...

Embodiment 3

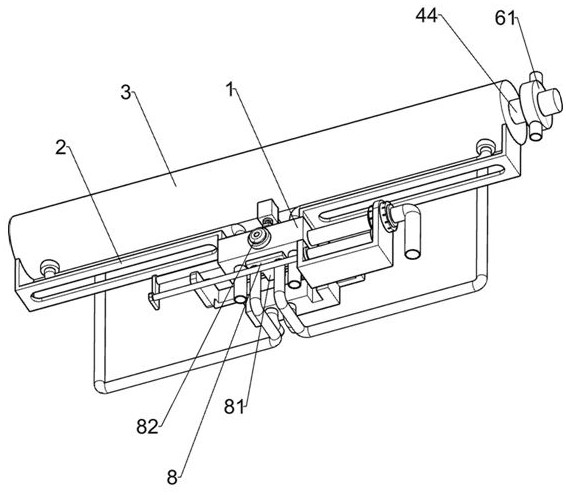

[0051] On the basis of Example 2, such as image 3 As shown, a warning part 8 is also included. The warning part 8 is arranged on the liquid guide frame 1. The warning part 8 is used to warn the staff to take corresponding treatment when the hydraulic oil temperature is high. The warning part 8 includes a negative temperature coefficient thermal The sensitive resistance plate 81 and the buzzer 82, the lower part of the outer side of the liquid guide frame 1 is fixedly connected with the negative temperature coefficient thermistor plate 81 for sensing the information of temperature rise, the liquid return pipe 74 and the negative temperature coefficient thermistor plate 81 Fixed connection, a buzzer 82 is fixed on the outer front side of the liquid guide frame 1, and the buzzer 82 is used to issue an alarm.

[0052] When the temperature of the hydraulic oil flowing through the liquid guide frame 1 through the liquid return pipe 74 is high, the negative temperature coefficient t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com