A method for high-precision photography and quality control of complex structural water engineering UAV

A quality control method and complex structure technology, applied in the direction of TV, color TV parts, TV system parts, etc., can solve the problems of low shooting flexibility, dam break, and lack of texture in oblique images, so as to ensure quality and job efficiency, reduce job time, and avoid the effect of texture compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] The present invention is to be applied to a large-scale hydropower UAV precision and quality control of the photography of the present invention in detail, the present invention is applicable to other complex structures UAV water engineering and quality control precision photography has the same guide.

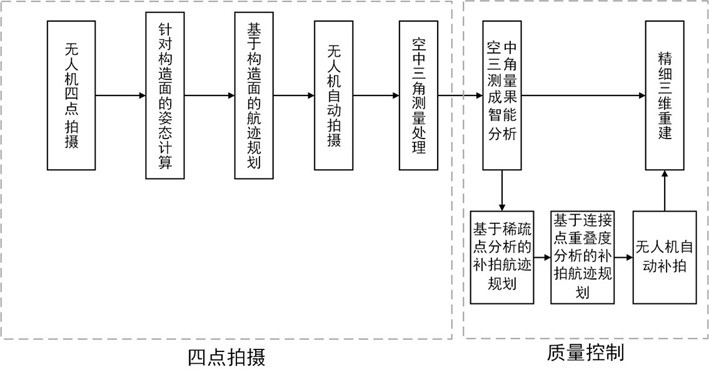

[0098] In this embodiment, a large high-precision photography UAV station and quality control method, comprising the steps of:

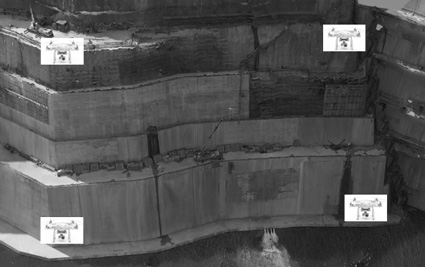

[0099] Geographical coordinates according to the characteristics of the shape of a large slope station, with manual shooting RTK UAV rotor in the vicinity of four corners of each face of a large-scale hydropower engineering goals to give the four corner points of the water: Step 1 (like figure 2 As shown in the white boxes represent rotorcraft UAV with RTK for imaging in the vicinity of four corners of each face of the station);

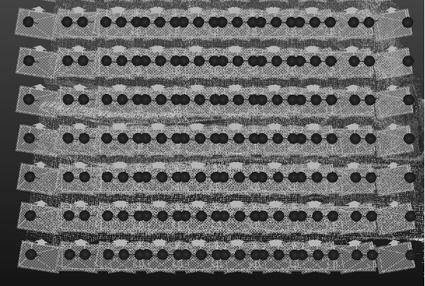

[0100] Step 2: Step 1 using the four corner points of the image obtained the drone, the calculated imaging range and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com