Brushless DC motor fuzzy PID control method based on neural network matrix

A brushless DC motor and neural network technology, which is applied in the field of brushless DC motor speed control, can solve the problem of poor processing effect of the uncertainty and nonlinear conditions of the brushless DC motor system, limited ability to adjust the dynamic characteristics of the control system, and difficult Control to achieve the expected effect and other problems, to solve the adaptive problem, facilitate training, and improve the applicability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

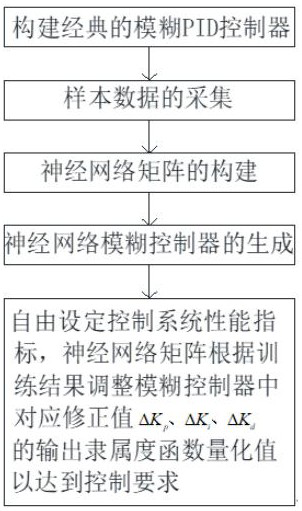

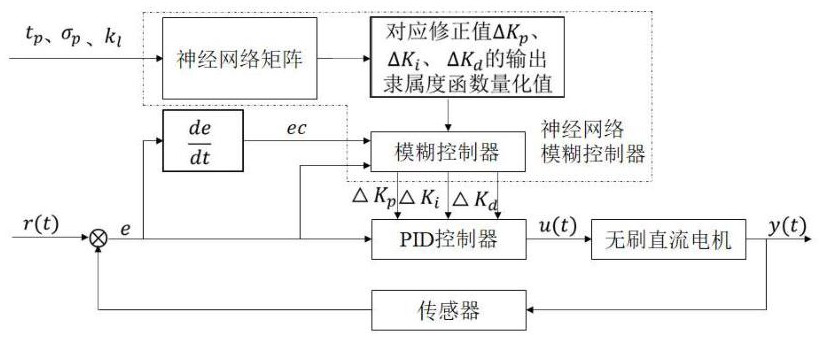

[0037] Such as figure 1 and figure 2As shown, in the control system, that is, the brushless DC motor double closed-loop speed control system, the inner loop current loop adopts typical PI control, and for the speed loop, a brushless DC motor fuzzy PID control method based on neural network matrix is adopted. The method steps are as follows:

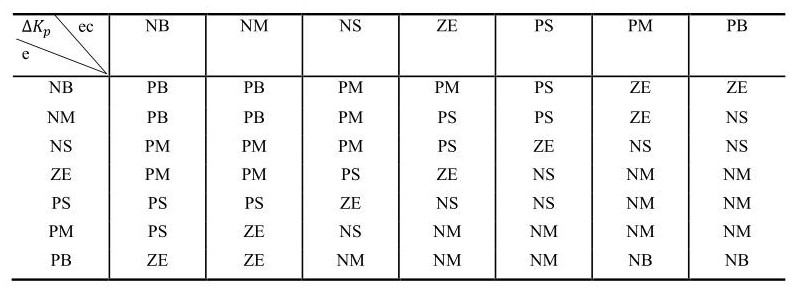

[0038] S1. Building a classic fuzzy PID controller: PID parameters , , The initial value of is adjusted to the vicinity of the control system operating parameters according to experience, and the fuzzy rules are set in a classical way (such as Figure 3-Figure 5 shown), adjust the corresponding correction value The output membership function quantifies the value to obtain different control effects;

[0039] S2. Collection of sample data: Obtain different system load parameters , peak time and the maximum overshoot The corresponding correction value in the fuzzy controller under the condition The output membership func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com