Preparation method of feed for metal injection molding, feed and metal part

A technology of injection molding and feeding, which is applied in the preparation of feeding materials for metal injection molding and the field of metal parts, and can solve problems such as single particle size distribution, poor mixing uniformity, and large density difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

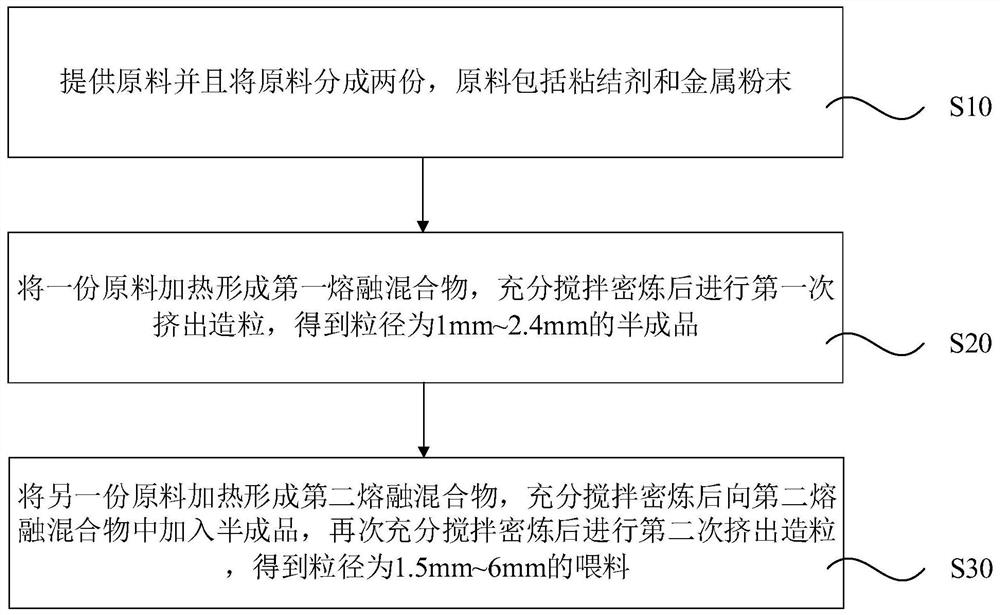

[0018] The invention discloses a method for preparing a feed material for metal injection molding in an embodiment, comprising the following steps:

[0019] S10. Provide raw materials and divide the raw materials into two parts, the raw materials include binder and metal powder.

[0020] It should be pointed out that, among the raw materials divided into two parts, the ratio of each component is exactly the same.

[0021] Generally speaking, the specific ratio of binder and metal powder in raw materials can be set according to actual needs.

[0022] Preferably, in the raw materials, the mass ratio of the binder to the metal powder is 1:8-16.

[0023] Metal powder can be purchased directly, or can be prepared by water atomization, gas atomization and other methods.

[0024] Preferably, the particle size of the metal powder is 10 μm to 200 μm.

[0025] The adhesive can be purchased directly, or can be configured according to the needs.

[0026] Preferably, in this embodiment...

Embodiment 1

[0056]Put 2000 parts of metal powder into the internal mixer and heat to 180°C, add 160 parts of binder, 12 parts of lubricant and 7 parts of antioxidant under stirring state, continue stirring to form the first molten mixture, fully stir the dense After 2 hours of refining, the first extrusion granulation was carried out to obtain a semi-finished product with a particle size of 2 mm. Wherein, the stirring speed is 15 rpm.

[0057] Put 2000 parts of metal powder into the internal mixer and heat to 180 ° C, add 160 parts of binder, 12 parts of lubricant and 7 parts of antioxidant under stirring state, continue stirring to form the second molten mixture, the second The molten mixture was fully stirred and banburyed for 2 hours, then the temperature was lowered to 40°C, then the semi-finished product was added and the temperature was raised to 40°C, and the second extrusion granulation was carried out after fully stirring and banburying for 30 minutes to obtain a feed material wi...

Embodiment 2

[0059] Put 2000 parts of metal powder into the internal mixer and heat to 160°C, add 160 parts of binder, 12 parts of lubricant and 7 parts of antioxidant under stirring state, continue stirring to form the first molten mixture, fully stir After 2 hours of refining, the first extrusion granulation was carried out to obtain a semi-finished product with a particle size of 1 mm. Wherein, the stirring speed is 15 rpm.

[0060] Put 2000 parts of metal powder into an internal mixer and heat to 160°C, add 160 parts of binder, 12 parts of lubricant and 7 parts of antioxidant under stirring, continue stirring to form the second molten mixture, and the second The molten mixture was fully stirred and banburyed for 2 hours, then the temperature was lowered to 20°C, then the semi-finished product was added and the temperature was raised to 20°C, and the second extrusion granulation was carried out after fully stirring and banburying for 15 minutes to obtain a feed material with a particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com