UASB reactor and hydraulic control method thereof

A technology of reactors and water pumps, applied in chemical instruments and methods, adjustment methods of biological treatment, biological water/sewage treatment, etc. The problem that the filter will not reach the best processing state can achieve the effect of improving the removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

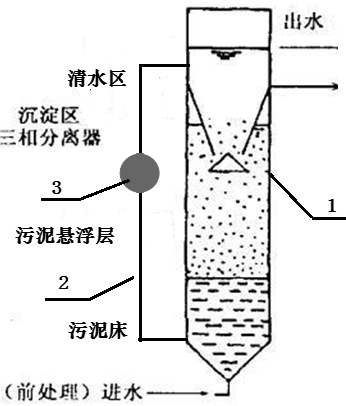

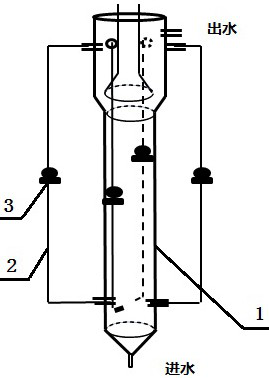

[0021] Such as figure 2 and image 3 As shown, the present invention provides a kind of UASB reactor, comprises in the reactor the sludge bed that is distributed with granular sludge, the sludge suspension layer that is distributed with flocculent sludge and accommodates the clear water area of clear water after treatment, refer to figure 1 Understand that the innovation of the present invention is that four return pipes 2 are also arranged in the reactor 1, the water inlet of the return pipe 2 is connected with the clean water area, and the water outlet of the return pipe 2 is arranged at the above sludge bed, from figure 2 It can be seen from the figure that the water inlet of the return pipe 2 is set at the upper part of the reactor 1, or near the top, and the water outlet of the return pipe 2 is set at the lower part of the reactor 1 or near the bottom.

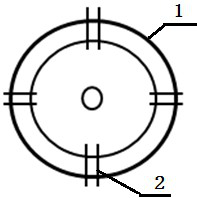

[0022] The water inlets of the four return pipes 2 are evenly distributed on the circumference, the angle between...

Embodiment 2

[0049] The difference between Embodiment 2 and Embodiment 1 is that the flow rate of each water pump 3 is controlled at 0.30 L / h.

Embodiment 3

[0051] The difference between Embodiment 3 and Embodiment 1 is that the flow rate of each water pump 3 is controlled at 0.46 L / h.

[0052] Use the treatment effect of reactor of the present invention to be:

[0053] Using the denitrification granular sludge cultivated in the present invention to treat nitrate wastewater, all of Examples 1-3 can achieve an average nitrate nitrogen removal rate of 95% and an average COD removal rate of more than 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com