Multistage filtering structure, motor controller and vehicle

A filter structure and controller technology, applied in the field of vehicles, can solve the problems of reducing production efficiency, increasing design difficulty, and compressing design space, and achieves the effects of simplified structure, novel structure and improved EMC capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

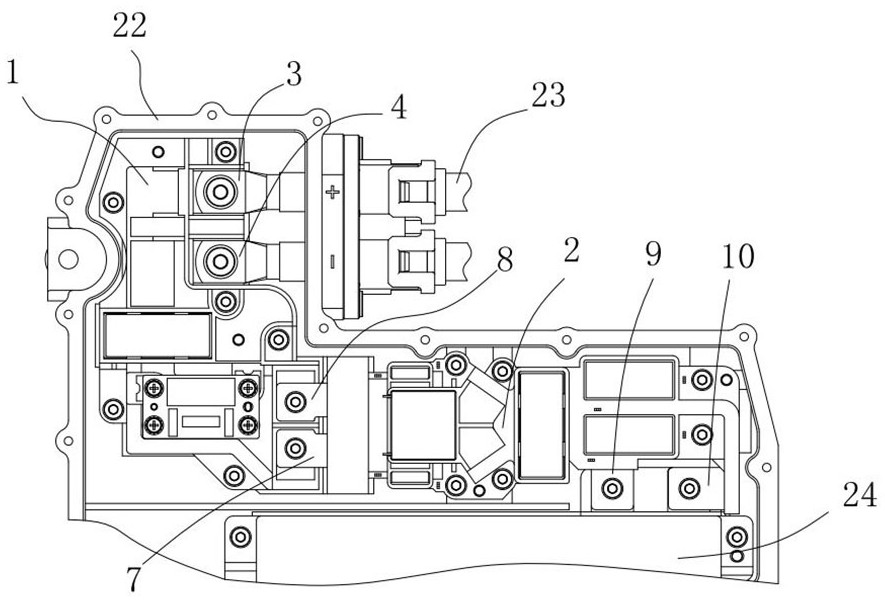

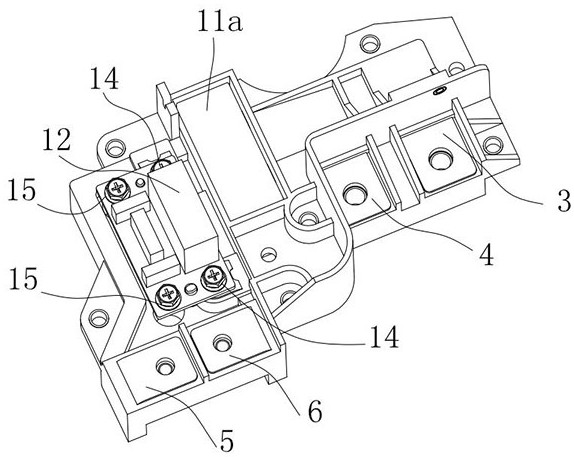

[0044] see Figure 1 to Figure 6 , a multi-stage filter structure of the embodiment of the present invention, the DC end fixed in the controller housing 22 is also the DC end, and the head end of the DC end is also as figure 1 The right side of the upper end shown is the high-voltage busbar 23, and the end is also as figure 1The lower end is shown as film capacitor 24 . The multi-stage filtering structure includes a primary filter fixing seat assembly 1 and a secondary filtering fixing seat assembly 2 . The primary filter fixing seat assembly 1 and the secondary filter fixing seat assembly 2 are horizontally arranged in the controller housing 22 . like figure 1 As shown, the left side of the controller housing 22 is the first-stage filter fixing seat assembly 1, and the right side of the controller housing 22 is the second-level filter fixing seat assembly 2. design space.

[0045] The input end of the high-voltage bus bar 23 is correspondingly connected to the positive a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com