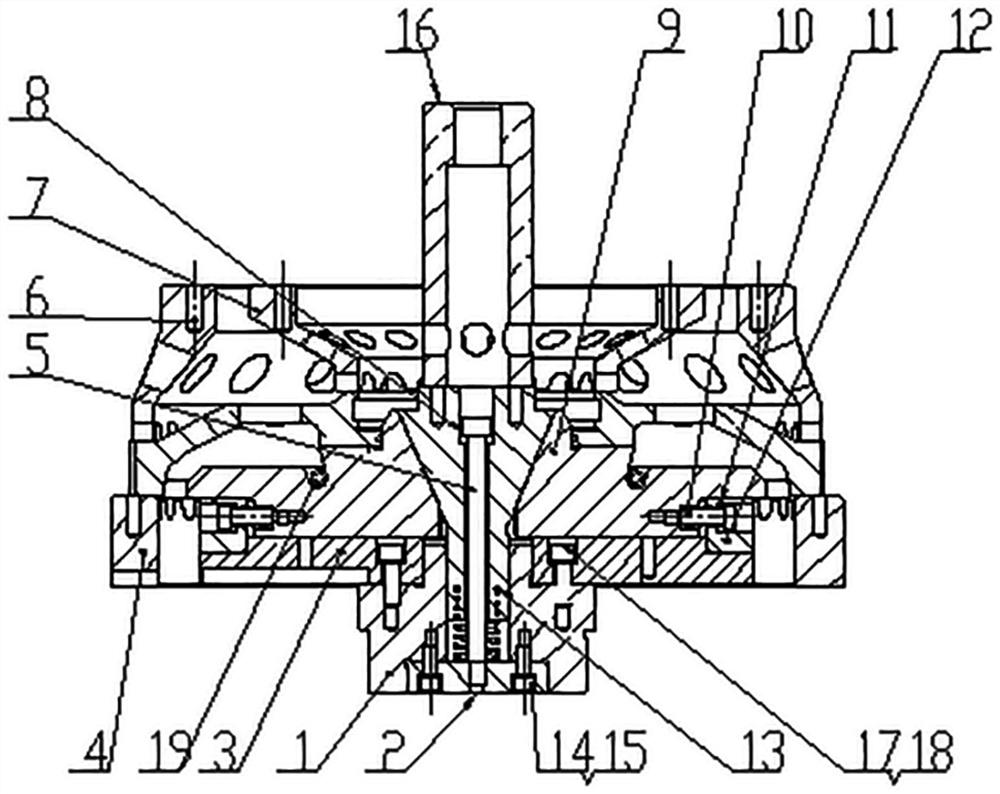

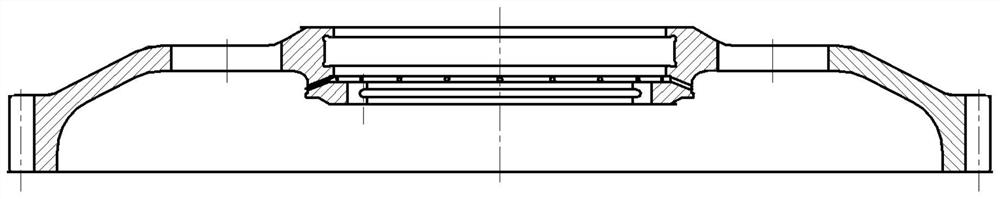

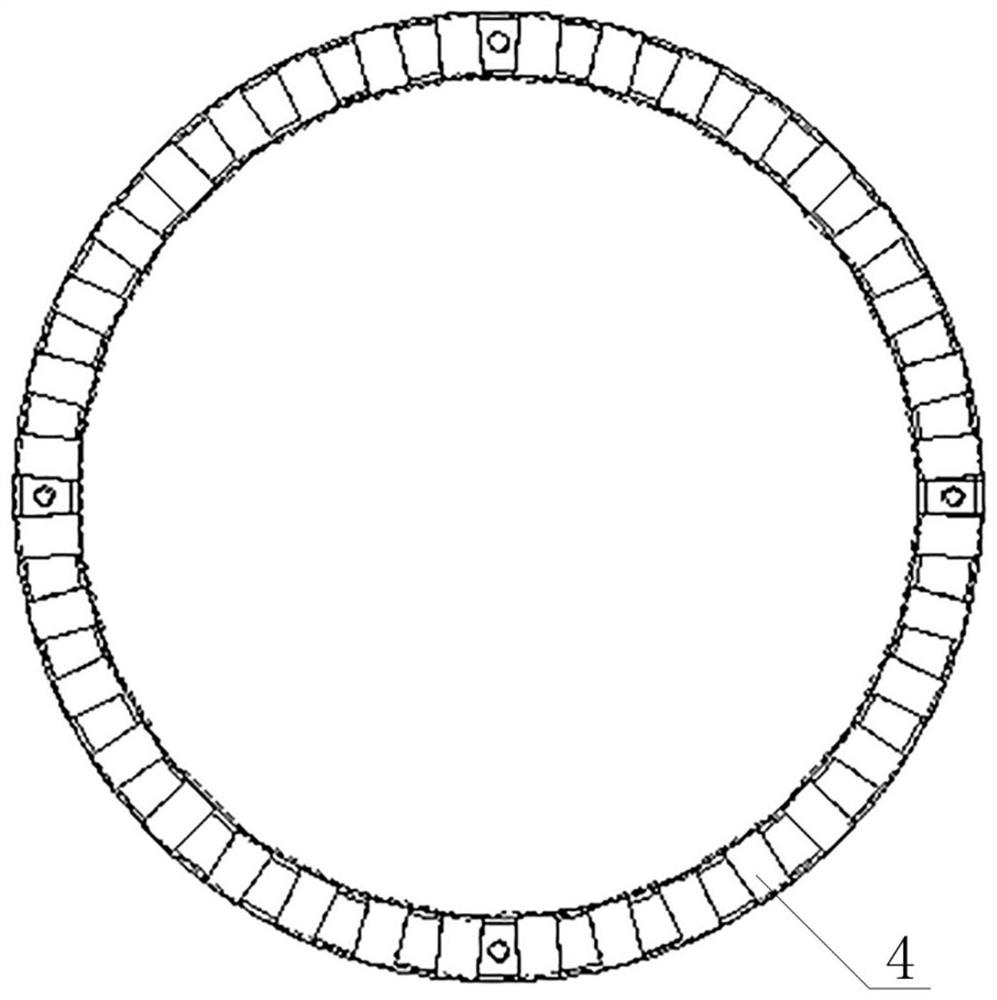

Pressure quenching die and technology for large-diameter thin arc plate carburized gear

A technology of carburizing gears and large diameters, which is applied in the direction of gears, metal material coating technology, forming tools, etc., can solve the problem of high heat treatment deformation control requirements, and achieve the effects of improving heat treatment quality, convenient operation, and eliminating temperature differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] S1. The part blank is a die forging. Before carburizing, the outer teeth, inner ring groove and groove bottom are all processed to a finishing allowance of about 0.3mm on one side. The arc plate is processed to the size required by the drawing, and anti-seepage paint is applied as required. ready for carburizing;

[0049] S2. The carburizing temperature is 930°C, the carburizing layer is (1.2-1.5) mm, and the carburizing equipment is an Ipsen controllable atmosphere multi-purpose furnace. The big end of the parts is placed flat on the material plate, and a 31mm high pad is used in the center block support;

[0050] S3. After carburizing + high-temperature tempering, scrub to remove the anti-seepage coating. The high-temperature tempering parameter is 640°C×240min, and then switch to quenching after high-temperature tempering;

[0051] S4. When quenching, put the large end of the part down and place it in an electric furnace for heating at a temperature of 800±10°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com