Device for renovating and repairing sand beach after typhoon

A beach and typhoon technology, which is applied in beach cleaning, transportation, packaging, filtering, etc., can solve the problems of manual sand repairing, heavy workload, slow collection and sieving efficiency, and poor collection effect, so as to maintain the soft effect and avoid sticking Knot, improve the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

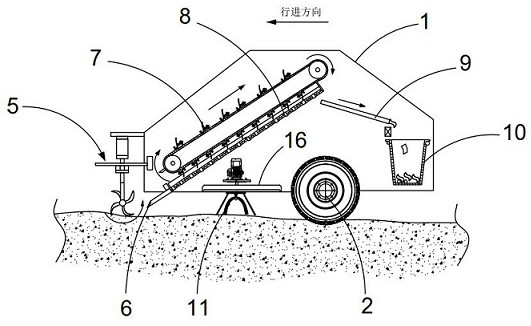

[0043] See attached figure 1 , 3 As shown in -4, a beach repair device after a typhoon, including:

[0044] Car body 1, the front end of the car body 1 is provided with a feed assembly 5, and the feed assembly 5 is used to push the material at the front end of the car body 1 backward,

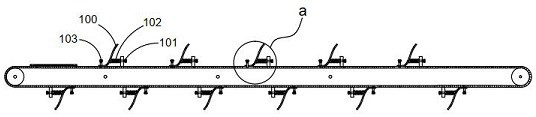

[0045] Conveyor belt group 7, the conveyor belt group 7 is arranged inside the car body 1, the conveyor belt group 7 is used to receive the material pushed by the feeding assembly, the transmission direction of the conveyor belt group 7 is inclined upward transmission, and the conveyor belt group 7 transmits out The material end is provided with a second sieve plate 9 inclined downwards, the two sides of the second sieve plate 9 are connected with the car body 1, and the discharge end of the second sieve plate 9 is provided with a Collecting box 10,

[0046] The conveyor belt group 7 includes a conveyor belt 701 and a driving wheel and a drive motor for driving the conveyor belt 701. The out...

Embodiment 2

[0054] Compared with embodiment 1, this embodiment is:

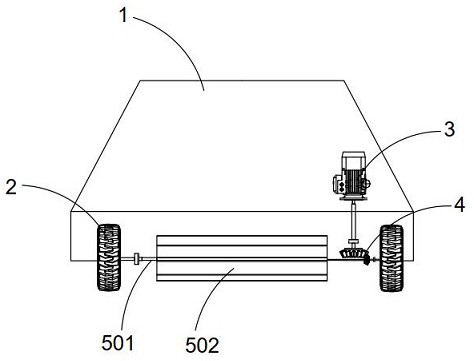

[0055] See attached figure 1 , 2 As shown, the feed assembly includes:

[0056] Feed shaft 501, the feed shaft 501 is horizontally arranged on the front side of the advancing end of the car body 1, the wheels 2 are connected to both sides of the feed shaft 501, and the feed shaft 501 connects the shaft body and the car through bearings. The front end of body 1 realizes the connection,

[0057] The first motor 3, the bottom of the first motor 3 is provided with a mounting plate, the mounting plate is connected to the car body 1, the output shaft of the first motor 3 is vertically arranged and connected with a bevel gear, and the feed shaft 501 Bevel gears corresponding to the first motor 3 are provided, and the two bevel gears form a bevel gear set 4,

[0058] Wherein, the feeding shaft 501 is surrounded by bent feeding blades 502 . The case design feeding assembly 5 is to advance sand into the sand playing plate 6 f...

Embodiment 3

[0061] Compared with embodiment 1, this embodiment is:

[0062] See attached figure 1 , 5As shown, the upper surface of the second sieve plate 9 is provided with buffer rubbers 901 at intervals, the buffer rubbers 901 are arranged in parallel with each other, and the thickness of the buffer rubbers 901 is less than 1 cm. In this case, the second sieve plate 9 is designed to receive the rubbish on the first sieve plate 8, and it is in an inclined downward setting state. The bulky garbage screened out will accelerate and fall on the second sieve plate 9 inclined downward under the action of gravity. The buffer rubber 901 can play a role in preventing the rapid falling of garbage, and through the obstacles of layers of buffer rubber 901, offset The falling impact force of the rubbish makes the rubbish fall smoothly into the collecting box 10 at the discharge end of the second sieve plate 9 . Garbage such as seaweed in the garbage is decelerated by layers of buffer rubber 901, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com