Laminated dryer for high-strength inner wallboard

An interior wall panel, high-strength technology, applied in dryers, drying, local stirring dryers, etc., can solve the problems of manual feeding, poor drying efficiency, high labor intensity, etc., and achieve convenient feeding operation. , High level of automation, the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

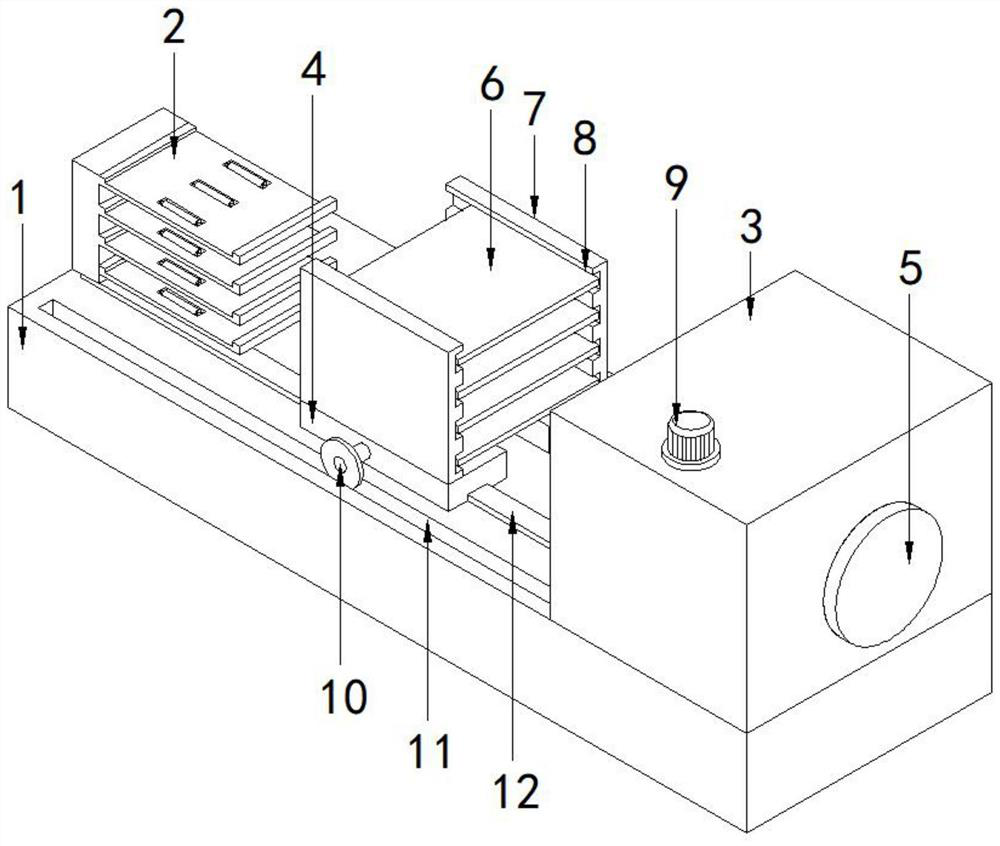

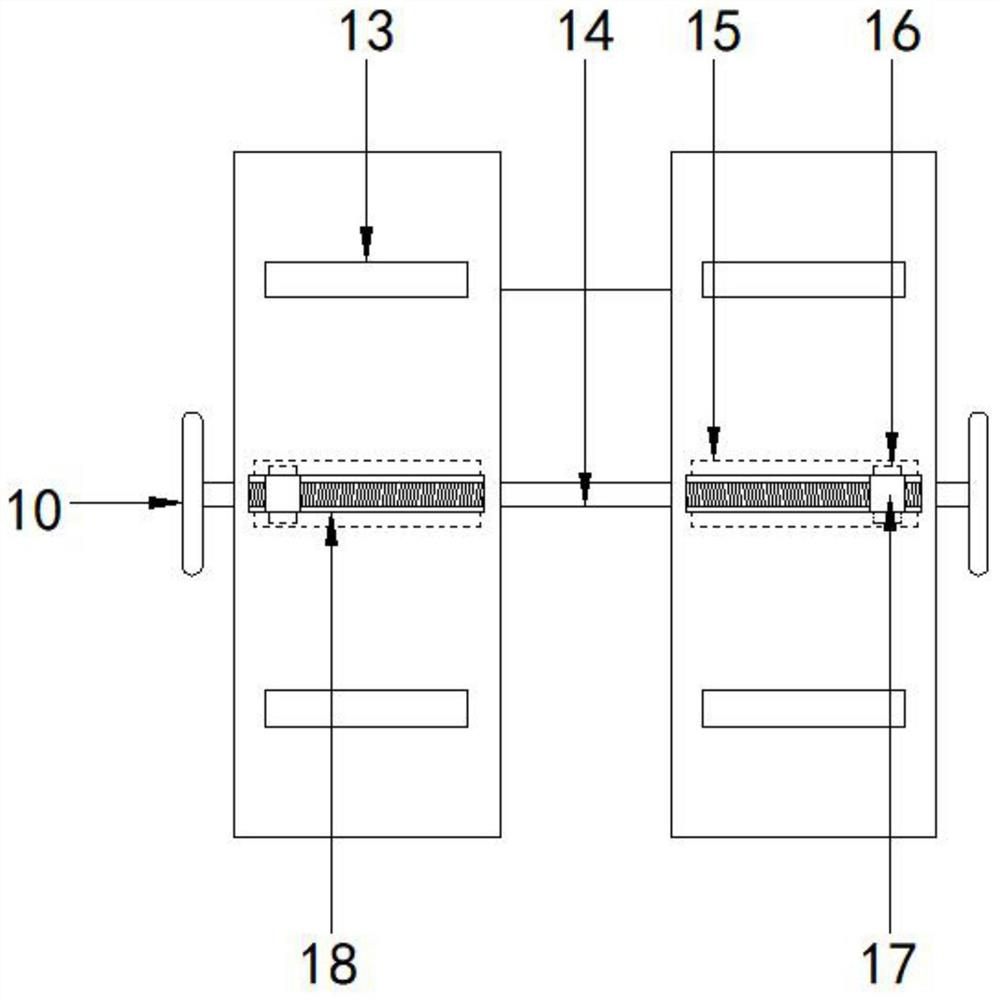

[0034] further improved, such as Figure 6As shown: the side wall of the drying box 3 is provided with an opening on the opposite side of the clamping mechanism, and several sets of extruding plates 34 are arranged symmetrically inside the drying box 3, and each group is respectively provided with two, between the two extruding plates 34 Extrusion chambers 35 are respectively formed between them, connecting plates 31 are respectively provided at both ends of the extruding plates 34, and threaded holes are provided on the surface of the connecting plates 31, and a transmission shaft 33 is arranged vertically in the inside of the drying box 3 symmetrically. The surface of 33 is symmetrically provided with several sets of threaded structures 36 and is connected with the threaded holes through the threaded structures 36 . One side of the top of the drying box 3 is equipped with a motor one 9, and the power output end of the motor one 9 extends to the inside of the drying box 3 and...

Embodiment 3

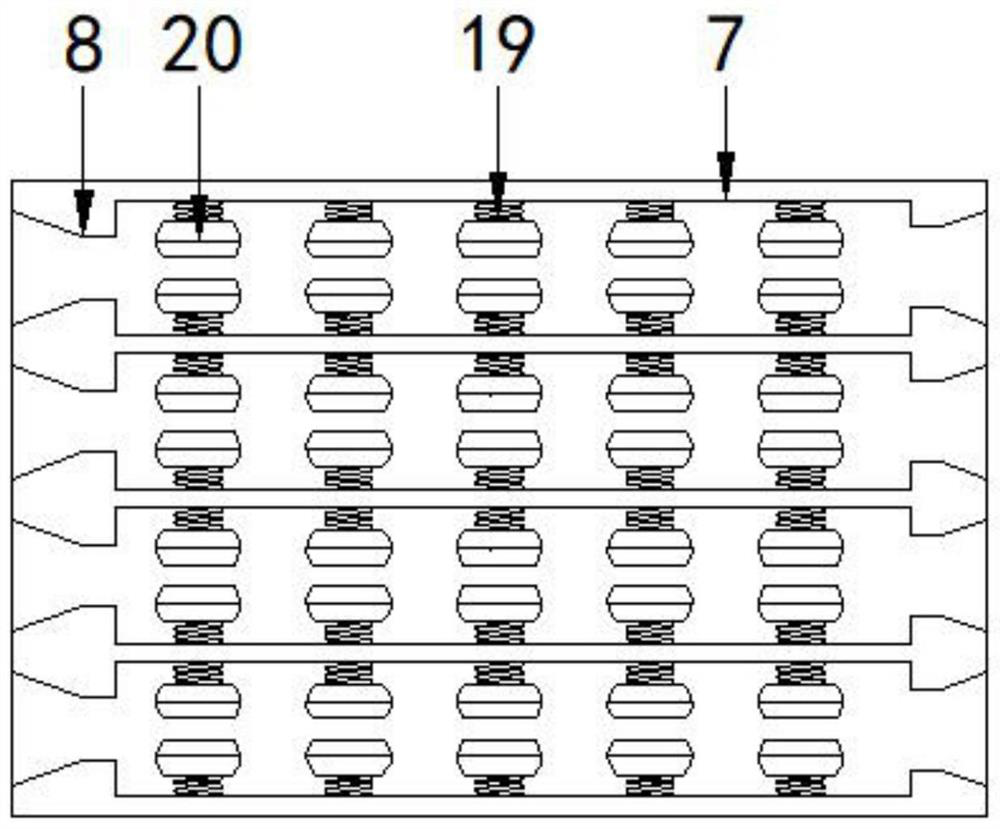

[0036] further improved, such as Figure 5 Shown: auxiliary driving mechanism comprises motor two 26, sprocket one 27, transmission wheel 30 and auxiliary driving roller 25, the surface of supporting plate 23 is provided with mounting groove 24, and the two ends of auxiliary driving roller 25 are respectively equipped with connecting shaft 28 and The connecting shaft 28 is connected to the supporting plate 23 in rotation, the end of the connecting shaft 28 extends to the fixed block 22 and connects to the sprocket 27, and the horizontally arranged sprockets 27 are connected by a chain 29, and the end of the connecting shaft 28 located in the middle Drive wheel 30 is also installed, adopts chain 29 to connect between drive wheel 30, drives auxiliary drive roller 25 to rotate by motor, promotes the wallboard 6 on the supporting plate 23 conveniently in the process of loading and unloading, improves the speed of loading and unloading.

[0037] When the present invention is in use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com