Electric arc furnace flame temperature measurement method and system based on visual perception

A visual perception, electric arc furnace technology, applied in the direction of sensing radiation from gas/flame, radiation pyrometry, measuring device, etc. Problems such as thermocouple sensors to avoid low detection accuracy, reliable data support, and improve stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

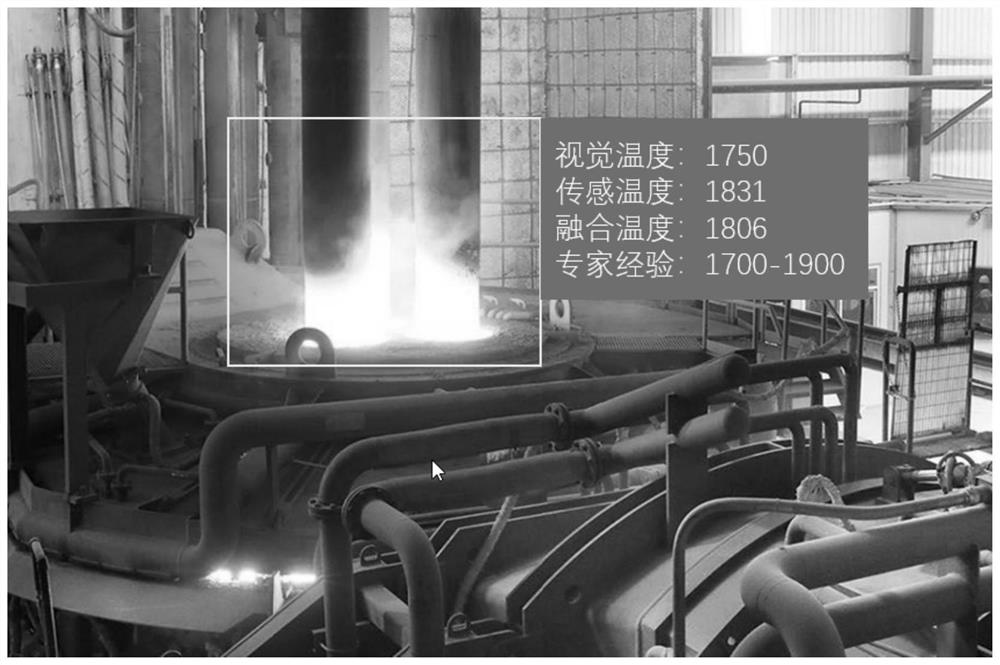

[0043] (1) The information processing unit determines the first preliminary temperature according to the original flame picture may include the following steps: the information processing unit performs picture processing on the original flame picture (the picture processing may include mean filtering, thresholding Existing image processing methods such as method image segmentation, distortion point correction, and grayscale conversion process the original flame image to obtain the grayscale histogram of the original flame image, and then obtain the grayscale histogram through the grayscale histogram. the gray scale value of the brighter area of the original flame picture) to obtain the gray scale value of the brighter area of the original flame picture, and then convert the gray scale value of the brighter area through a predetermined brightness temperature conversion model, Thus the first preliminary temperature is obtained. In practical applications, the predetermined br...

Embodiment 1

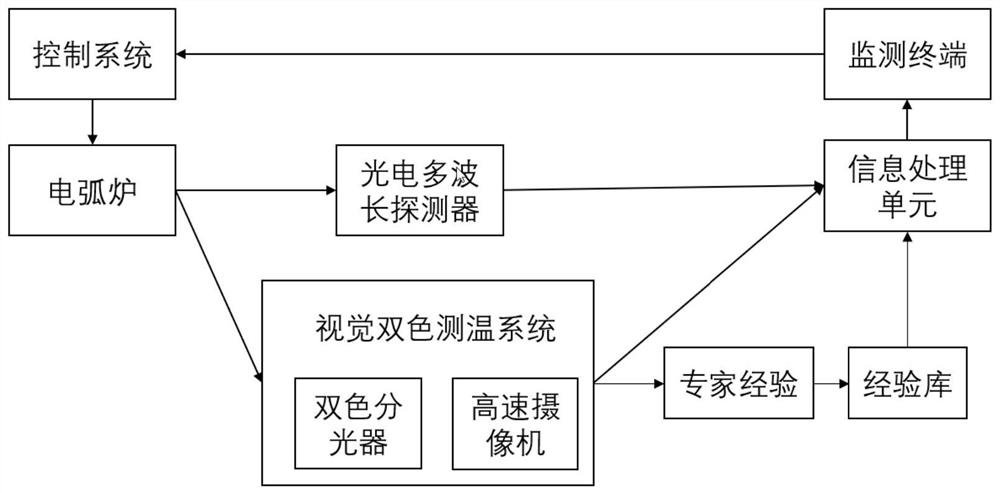

[0056] Such as figure 1 As shown, a visual perception-based electric arc furnace flame temperature measurement system is used for such as figure 2 The flame of an electric arc furnace shown is used for temperature measurement. The specific structure may include: a visual two-color temperature measurement system, a photoelectric multi-wavelength detector, an information processing unit, a monitoring terminal and an electric arc furnace control system. The visual two-color temperature measurement system and the photoelectric multi-wavelength detector monitor the flame temperature of the electric arc furnace respectively, and the visual two-color temperature measurement system and the photoelectric multi-wavelength detector are respectively electrically connected to the information processing unit, so The information processing unit is electrically connected to the monitoring terminal, the monitoring terminal is connected to the electric arc furnace control system, and the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com