Numerical control machine tool spindle power signal processing method and device, and electronic equipment

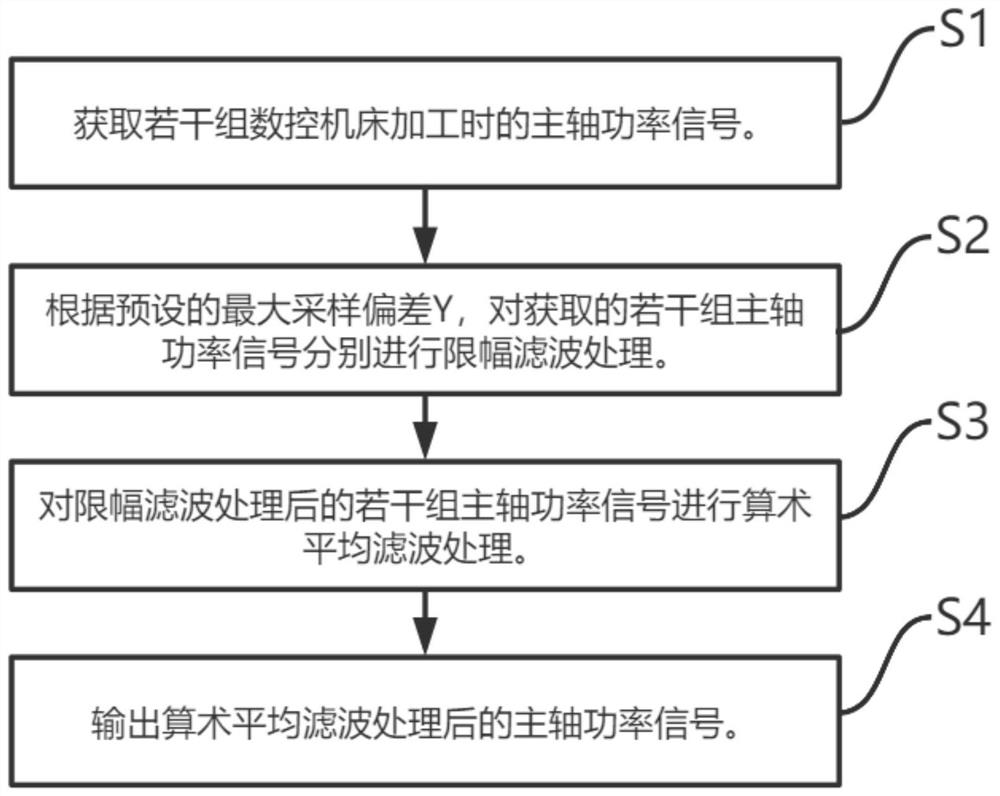

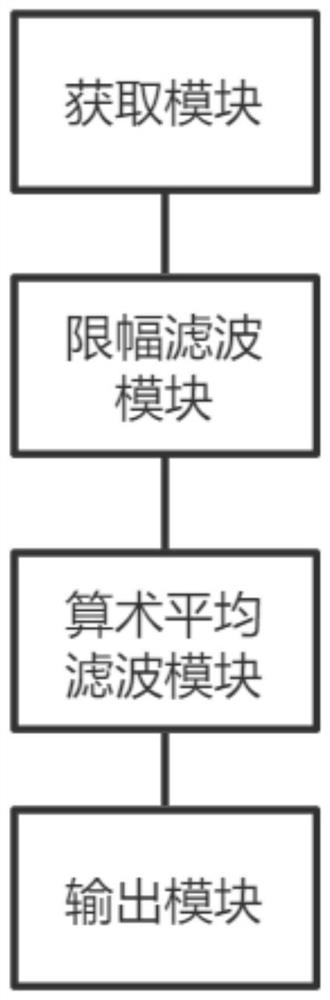

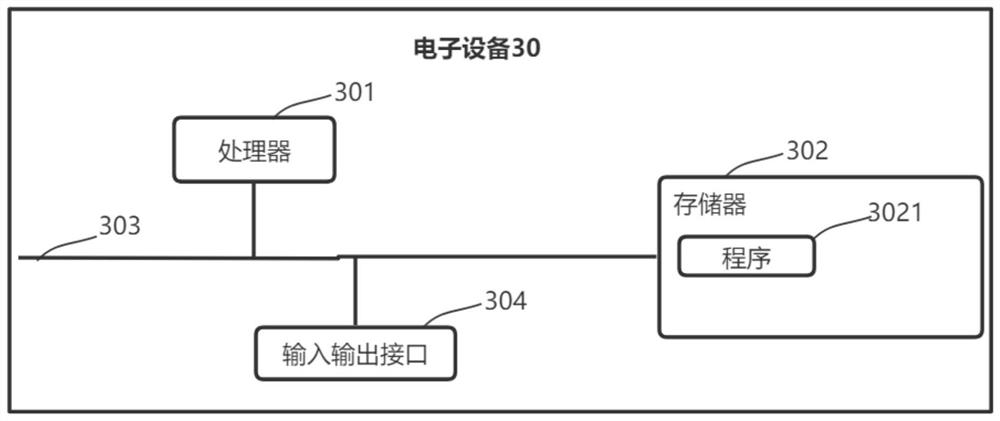

A technology of power signal and CNC machine tool, which is applied in the direction of program control, computer control, general control system, etc., can solve the problem of strong interference of the power signal of the spindle of CNC machine tool, so as to save processing time, improve processing efficiency, improve accuracy and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] Pre-set the maximum sampling deviation Y: Connect one end of the power sensor WT800 to the output end of the spindle motor of the CNC machine tool. At this time, the processing parameters of the machine tool are: spindle speed 6000r / min, cutting depth 0.5mm, feed speed 5m / min, and repeat the acquisition for 3 groups The spindle power signal during CNC machine tool processing is shown in Table 1:

[0065]

[0066]

[0067] Table 1

[0068] Set 0.1, 0.3, and 0.5 as the maximum sampling deviation, and perform limiting filter processing on the original spindle power signal collected in Table 1.

[0069] Calculate the variance of all test power signals processed by limiting filtering, and the results are shown in Table 2.

[0070]

[0071] Table 2

[0072] It can be seen that the maximum sampling deviation corresponding to the smallest variance is 0.1, and the maximum sampling deviation Y is set to 0.1.

[0073] S1: Connect one end of the power sensor to the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com