Semiconductor chilling plate and manufacturing method thereof

A technology of semiconductors and refrigerating sheets, which is applied in the field of semiconductor refrigerating sheets and its production, and can solve problems such as poor anti-overload ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

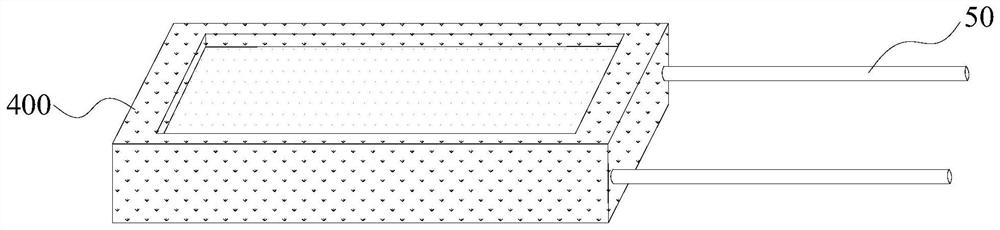

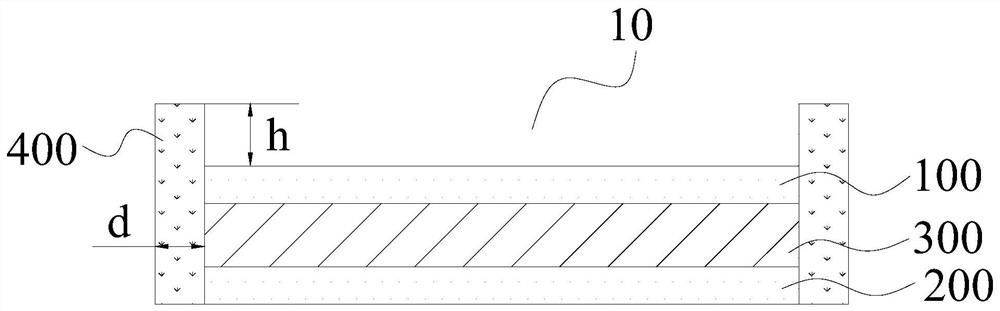

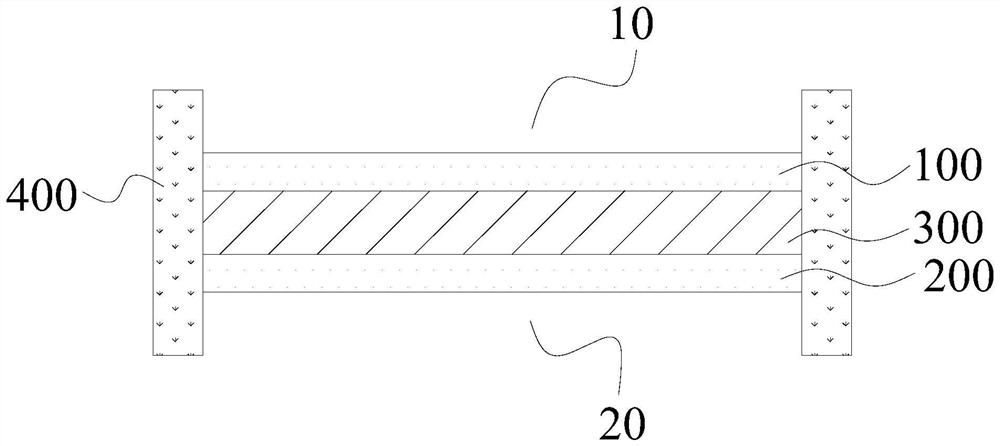

[0058] The semiconductive refrigeration sheet includes a semiconductive refrigeration assembly and a packaging structure, and the semiconductive refrigeration assembly includes a first insulating and heat conducting layer and a second insulating and heat conducting layer oppositely arranged, and a semiconductor layer located between the first insulating and heat conducting layer and the second insulating and heat conducting layer, The side of the semi-conductor refrigeration assembly provided with the first insulating and heat-conducting layer is the cold end, and the side provided with the second insulating and heat-conducting layer is the hot end. The packaging structure covers the side wall of the semiconductor refrigeration assembly and forms a second A groove, at the same time forming a second groove with the second insulating and heat-conducting layer.

[0059] Both the first insulating and heat-conducting layer and the second insulating and heat-conducting layer are cera...

Embodiment 2

[0067] The structure and manufacturing process of the semiconductor refrigeration chip of this embodiment are basically the same as that of Embodiment 1, the difference is that the wall thickness of the packaging structure is 0.8mm, the depth of the first groove and the second groove are both 0.6mm, injection molding The temperature is 240°C, the injection pressure is 40bar, and the curing time is 50s.

Embodiment 3

[0069] The structure and manufacturing process of the peltier cooler in this embodiment are basically the same as in Embodiment 1, except that the wall thickness of the packaging structure is 1 mm, and the depths of the first groove and the second groove are both 1 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com