Method for preparing healthy fat substitute based on pea/mung bean protein

A fat substitute, mung bean protein technology, applied in the field of oil and emulsified fat products, can solve the problems of difficult preparation, weak gel properties, etc., achieve good plasticity, low saturated fatty acid content, and expand the application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

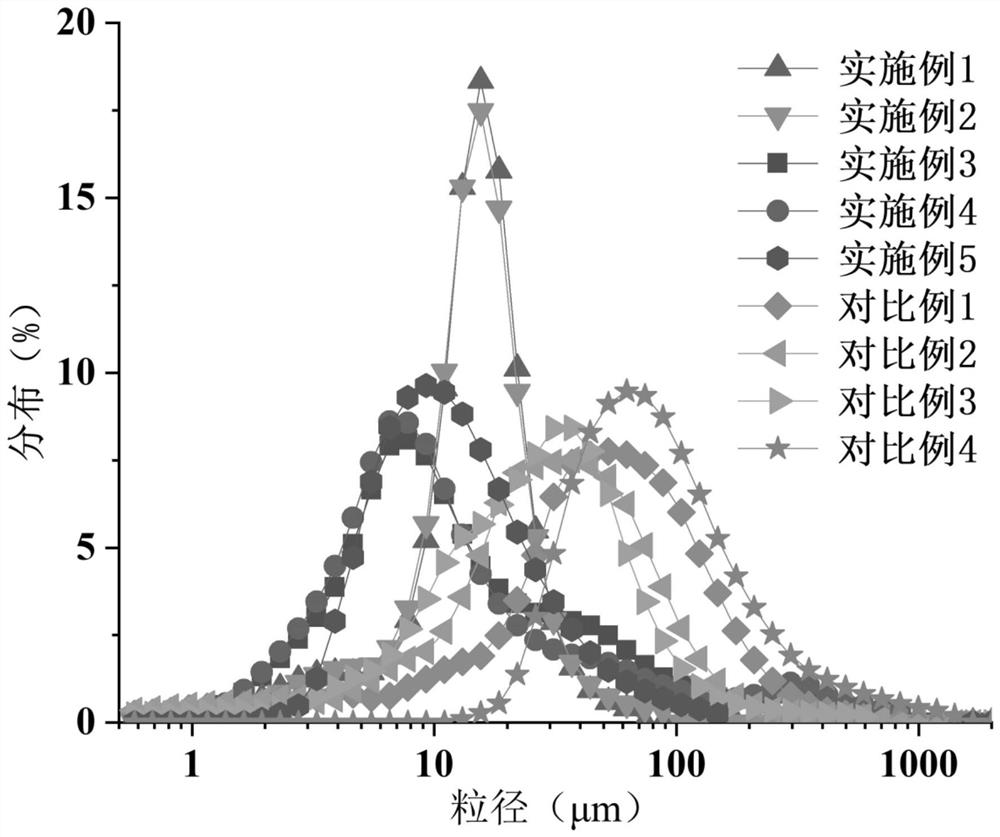

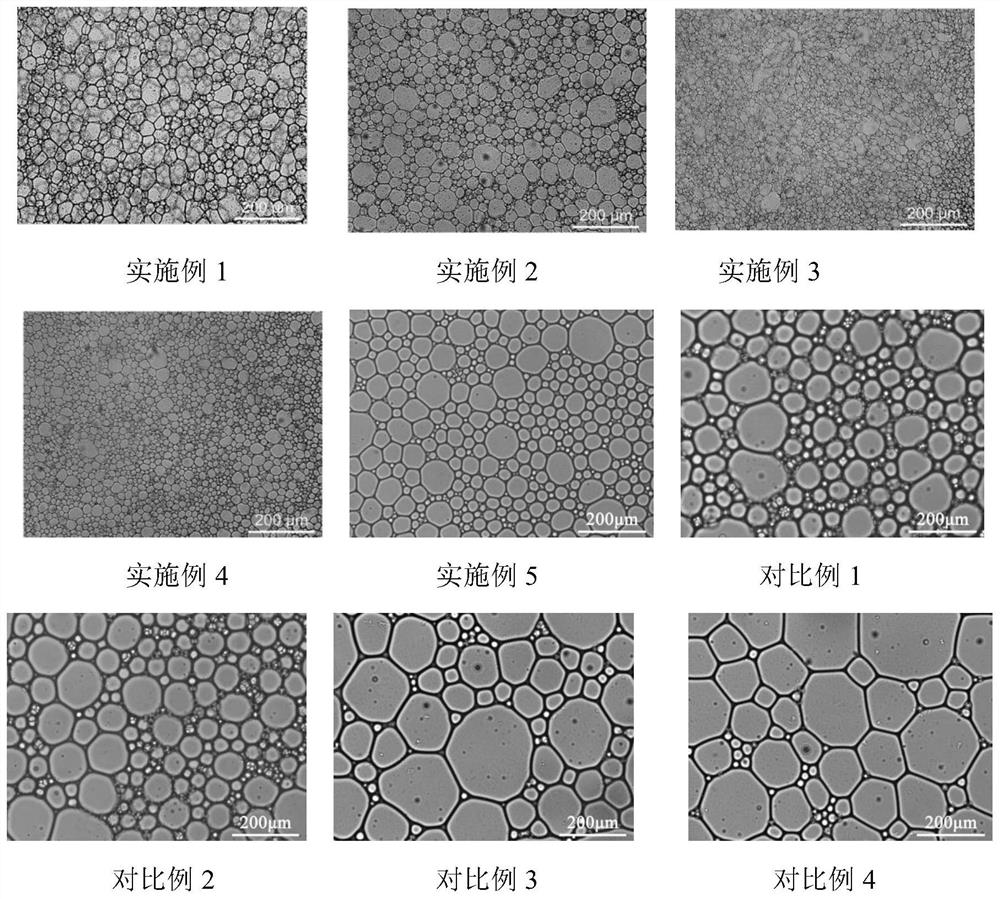

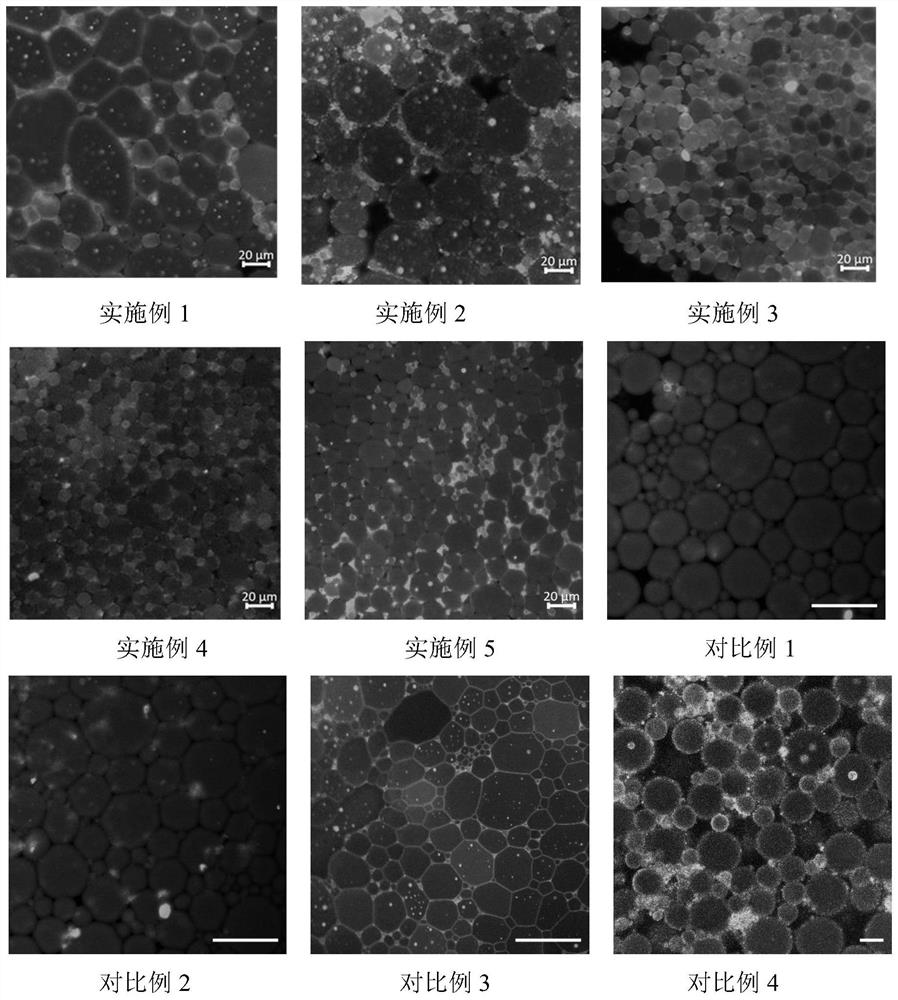

Embodiment 1

[0069] A method for preparing a healthy fat substitute only based on nanoscale pea protein isolate, comprising the steps of:

[0070] (1) Using phosphate buffer as a solvent, prepare a pea protein isolate solution with a mass concentration of 15%, fully stir it with a stirrer at 300 rpm for 2 hours, adjust the pH value to 7.0, and place it in a refrigerator at 4°C for 12 hours to fully hydrate the protein. A hydrated pea protein isolate solution is obtained;

[0071] (2) The hydrated pea protein isolate solution obtained in step (1) is subjected to high-speed shearing (10000rpm treatment for 2min) and high-pressure homogenization (100Mpa treatment for 3min) to obtain a nanoscale pea protein isolate dispersion;

[0072] (3) heating the nanoscale protein isolate dispersion in step (2) in a water bath at 80°C for 20 minutes, and then cooling to 40°C to obtain a modified pea protein isolate dispersion;

[0073] (4) Add 15U / g transglutaminase TGase to the pea protein isolate dispe...

Embodiment 2

[0077] A method for preparing a healthy fat substitute only based on nano-scale mung bean protein isolate, comprising the steps of:

[0078] (1) Using phosphate buffer as a solvent, prepare mung bean protein isolate solution with a mass concentration of 15%, fully stir with a stirrer at 300 rpm for 2 hours, adjust the pH value to 7.0 and place it in a refrigerator at 4°C for 12 hours to fully hydrate the protein. Obtain the mung bean protein isolate solution after hydration;

[0079] (2) The hydrated mung bean protein isolate solution obtained in step (1) is subjected to high-speed shearing (10000rpm treatment for 2min) and high-pressure homogenization (100Mpa treatment for 3min) to obtain a nano-scale mung bean protein isolate dispersion;

[0080] (3) heating the nanoscale protein isolate dispersion in step (2) in a water bath at 80°C for 20 minutes, and then cooling to 40°C to obtain a modified mung bean protein isolate dispersion;

[0081] (4) Add 15U / g transglutaminase TG...

Embodiment 3

[0085] A method for preparing a healthy fat substitute based on nanoscale pea protein isolate-xanthan gum (XG), comprising the steps of:

[0086] (1) Using phosphate buffer as a solvent, prepare a pea protein isolate solution with a mass concentration of 15%, fully stir it with a stirrer at 300 rpm for 2 hours, adjust the pH value to 7.0, and place it in a refrigerator at 4°C for 12 hours to fully hydrate the protein. A hydrated pea protein isolate solution is obtained;

[0087] (2) The hydrated pea protein isolate solution obtained in step (1) is subjected to high-speed shearing (10000rpm treatment for 2min) and high-pressure homogenization (100Mpa treatment for 3min) to obtain a nanoscale pea protein isolate dispersion;

[0088] (3) heating the nanoscale protein isolate dispersion in step (2) in a water bath at 80°C for 20 minutes, and then cooling to 40°C to obtain a modified pea protein isolate dispersion;

[0089] (4) Add 15U / g transglutaminase TGase to the pea protein i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com