Novel defoaming agent and preparation method thereof

A defoamer, a new type of technology, applied in the direction of separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve the problems of poor stability of defoamers, difficulty in achieving the use effect, and affecting the use of defoamers, etc., to achieve good results Frost resistance, excellent compatibility, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The composition of each material is as follows: 100 parts of kitchen waste oil, 2 parts of ethanol, 4 parts of modified silicone oil, 3 parts of hydrophobic silicon dioxide, 4 parts of paraffin wax, 3 parts of PE wax, 8 parts of metal soap, 12 parts of emulsifier, dispersant 6 doses.

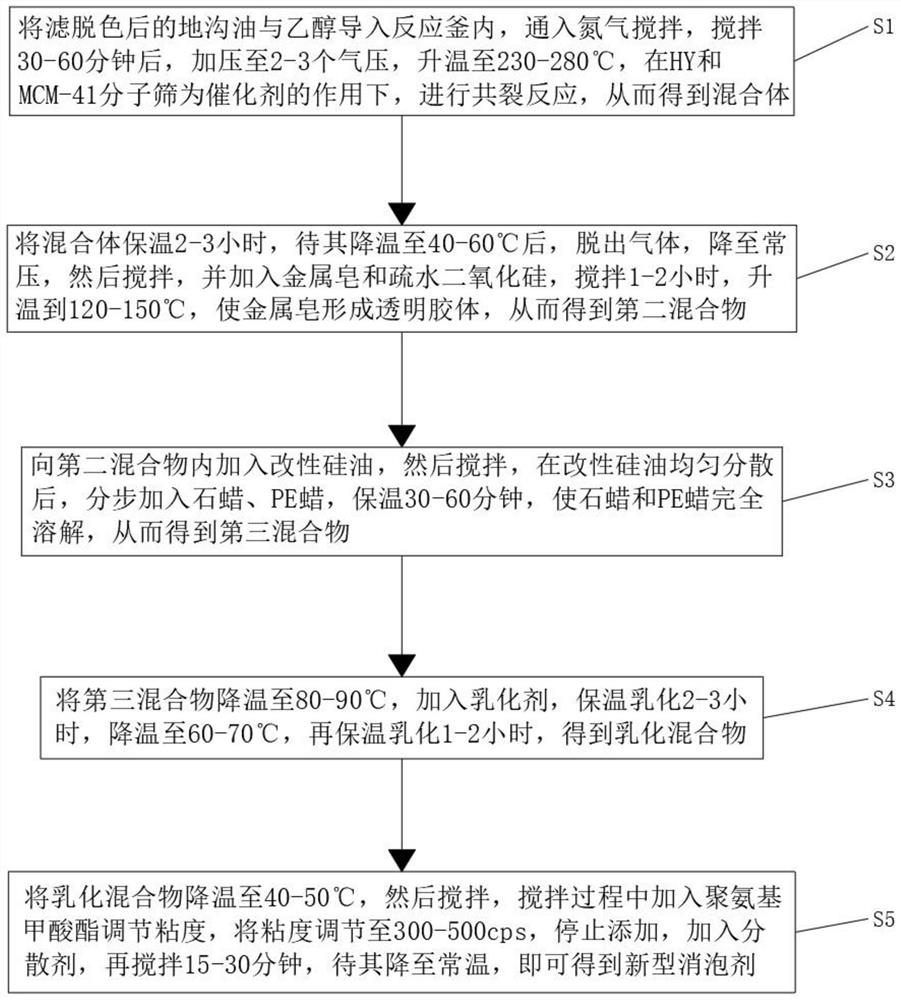

[0028] The preparation method of novel defoamer, comprises the following steps:

[0029] S1: Purchase and filter decolorized kitchen waste oil, then introduce an appropriate amount of kitchen waste oil and ethanol into the reaction kettle, and pass nitrogen into the reaction kettle for protection, and then stir at a stirring speed of 180 Turn per minute, stir for 40 minutes, gradually increase the pressure to 2 atmospheric pressure, and raise the temperature to 250 ° C, under the action of HY and MCM-41 molecular sieve as a catalyst, carry out co-cleavage reaction to obtain a mixture;

[0030] S2: Keep the mixture obtained in S1 in the reactor for 2 hours. After it cools down to 50°C, th...

Embodiment 2

[0035]The composition of each material is as follows: 100 parts of kitchen waste oil, 3 parts of ethanol, 5 parts of modified silicone oil, 4 parts of hydrophobic silicon dioxide, 5 parts of paraffin wax, 5 parts of PE wax, 10 parts of metal soap, 15 parts of emulsifier, dispersant 8 doses.

[0036] The preparation method of novel defoamer, comprises the following steps:

[0037] S1: Purchase and filter decolorized kitchen waste oil, then introduce an appropriate amount of kitchen waste oil and ethanol into the reaction kettle, and pass nitrogen into the reaction kettle for protection, and then stir at a stirring speed of 200 Rotate per minute, after stirring for 50 minutes, gradually increase the pressure to 2.5 atmospheric pressure, and raise the temperature to 260 ° C, under the action of HY and MCM-41 molecular sieve as a catalyst, carry out a co-cracking reaction to obtain a mixture;

[0038] S2: Keep the mixture obtained in S1 in the reactor for 2 hours. After it cools ...

Embodiment 3

[0043] The composition of each material is as follows: 100 parts of kitchen waste oil, 3 parts of ethanol, 4 parts of modified silicone oil, 5 parts of hydrophobic silicon dioxide, 4 parts of paraffin wax, 5 parts of PE wax, 9 parts of metal soap, 14 parts of emulsifier, dispersant 10 doses.

[0044] The preparation method of novel defoamer, comprises the following steps:

[0045] S1: Purchase and filter decolorized kitchen waste oil, then introduce an appropriate amount of kitchen waste oil and ethanol into the reaction kettle, and pass nitrogen into the reaction kettle for protection, and then stir at a stirring speed of 220 Rotate per minute, after stirring for 50 minutes, gradually increase the pressure to 3 atmospheric pressure, and raise the temperature to 270 ° C, under the action of HY and MCM-41 molecular sieve as a catalyst, carry out co-cleavage reaction to obtain a mixture;

[0046] S2: Keep the mixture obtained in S1 in the reactor for 2.5 hours. After it cools d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com