A high-concentration odor treatment process

A treatment process, high-concentration technology, applied in the direction of air quality improvement, separation method, dispersed particle separation, etc., to achieve the effect of reducing treatment time, reducing treatment cost, and improving deodorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

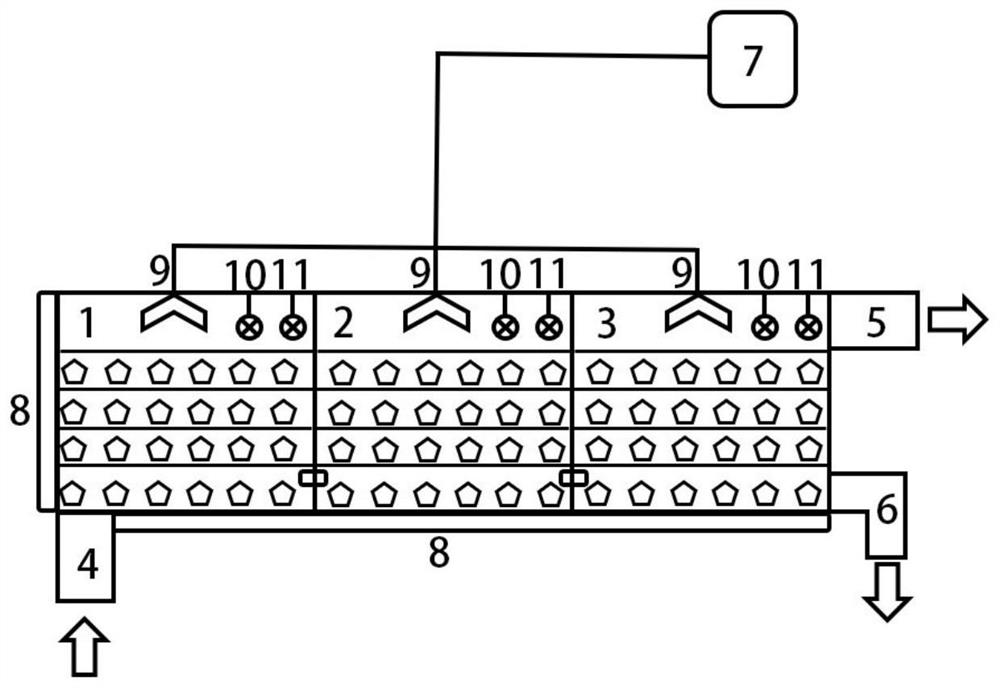

[0026] like figure 1 As shown, the biological filter box of the present application is divided into three independent chambers 1, 2, and 3, and the combination ratios of the microbial strains of the biological fillers in the chambers 1, 2, and 3 are different, and the first chamber 1 is connected to the air inlet pipeline. 4. The third chamber is connected to the air outlet pipeline 5 and the waste liquid discharge pipeline 6. H is set in the chambers 1, 2, and 3. 2 S Concentration Monitor 10 and NH 3 The concentration monitor 11 and the nutrient solution spraying device 9, the nutrient solution is provided by the nutrient solution supply device 7, the weight ratio of microorganisms in the biological fillers in the first, second and third chambers is 7%, and the first, second, A thermometer and a temperature control device 8 are arranged in the third chamber, the temperature control device is a cooling device, and the temperature in the chamber is kept at 29-32°C; the treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com