High-power ball mill energy-saving control method based on global synergy optimization energy-saving technology

An energy-saving control, ball mill technology, applied in grain processing and other directions, can solve the problem that the workload is not directly related, and achieve the effect of reducing self-loss and fast ball milling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

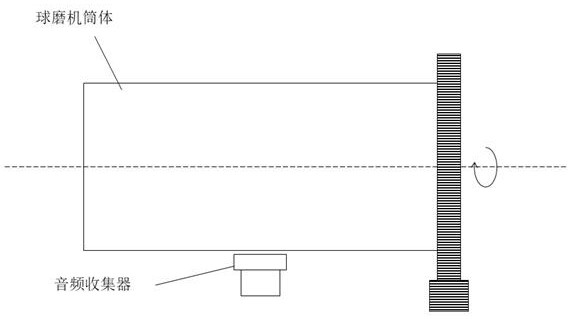

[0044] combine Figure 1-2 , an energy-saving control method for high-power ball mills based on global efficiency-enhancing optimization energy-saving technology, comprising the following steps:

[0045] Step 1: Put the mineral material and grinding balls into the barrel of the ball mill, and inject a predetermined amount of water, start the audio collector to collect the audio signal in the barrel of the ball mill, turn on the ball mill and start ball milling at a stable speed;

[0046] Step 2: Take samples from the barrel of the ball mill at intervals of 10 minutes during the ball milling process, and put the samples into the shrinkage analyzer for shrinkage analysis; divide the particle size of the mineral material into n levels, where n≥5; the shrinkage analyzer obtains The ratio of mineral materials of each particle size in the ball mill cylinder at the current moment; at the same time, the audio signal in the ball mill cylinder collected by the audio collector within 10s...

Embodiment 2

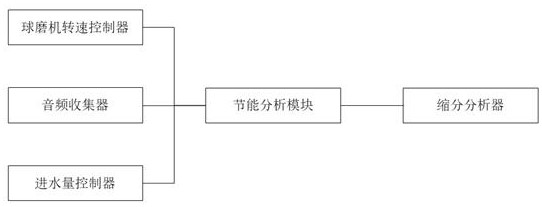

[0061] An energy-saving control system for implementing the method, characterized by comprising:

[0062] Ball mill, ball mill speed controller, energy-saving analysis module, audio collector, water inflow controller and shrinkage analyzer;

[0063] The audio collector is installed at the bottom of the outer wall of the ball mill cylinder, and is liquid-coupled with the ball mill cylinder to collect the vibration sound signal in the ball mill cylinder and send the signal to the energy-saving analysis module;

[0064] The energy-saving analysis module performs Fourier transform on the audio signal of the audio collector mobile phone to obtain the frequency spectrum of the audio signal, and inputs the frequency spectrum of the audio signal into the spectrum-particle size analysis model to obtain the proportion of mineral materials in each particle size range in the ball mill;

[0065] The ball mill speed controller controls the speed of the ball mill cylinder, and the water inle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap