Low-carbon environment-friendly biodegradable quenching oil and preparation method thereof

A biodegradable, low-carbon and environmentally friendly technology, applied in the field of quenching oil, can solve the problems of not easy biodegradation, large environmental pollution, and non-environmental protection, and achieve the effect of easy biodegradation, good stability, and less carbon residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

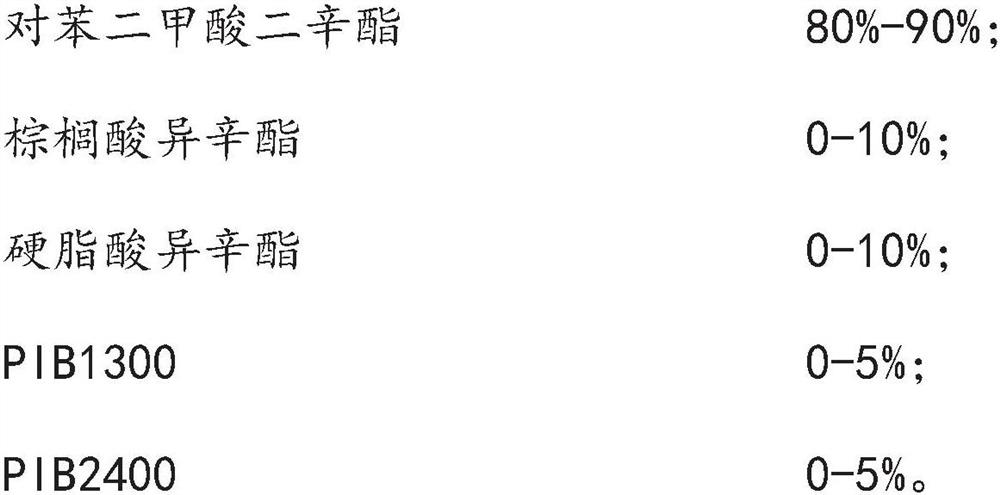

[0022] Take the preparation material of quenching oil comprising the following weight percentages: dioctyl terephthalate 82%; isooctyl palmitate 10%; isooctyl stearate 3%; PIB13004%; PIB24001%.

[0023] Add dioctyl terephthalate, isooctyl palmitate, and isooctyl stearate into the blending kettle, heat to 50-60°C to form a mixture; add PIB1300 and PIB2400 heated to 50-60°C respectively Stir well in the above mixture.

Embodiment 2

[0025] Take the preparation material of quenching oil comprising the following weight percentages: dioctyl terephthalate 80%; isooctyl palmitate 10%; isooctyl stearate 5%; PIB13001%; PIB24004%.

[0026] Add dioctyl terephthalate, isooctyl palmitate, and isooctyl stearate into the blending kettle, heat to 50-60°C to form a mixture; add PIB1300 and PIB2400 heated to 50-60°C respectively Stir well in the above mixture.

Embodiment 3

[0028] Take the preparation material of quenching oil comprising the following weight percentages: dioctyl terephthalate 90%; isooctyl palmitate 4%; isooctyl stearate 1%; PIB13002%; PIB24003%.

[0029] Add dioctyl terephthalate, isooctyl palmitate, and isooctyl stearate into the blending kettle, heat to 50-60°C to form a mixture; add PIB1300 and PIB2400 heated to 50-60°C respectively Stir well in the above mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com