Transparent flexible packaging bag static detection method and system based on machine vision

A technology of machine vision and static detection, applied in neural learning methods, instruments, computer components, etc., can solve problems such as data volume and dimension growth, affecting computing efficiency and classification and recognition performance, so as to improve performance and reduce data processing Complexity, the effect of reducing computational complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

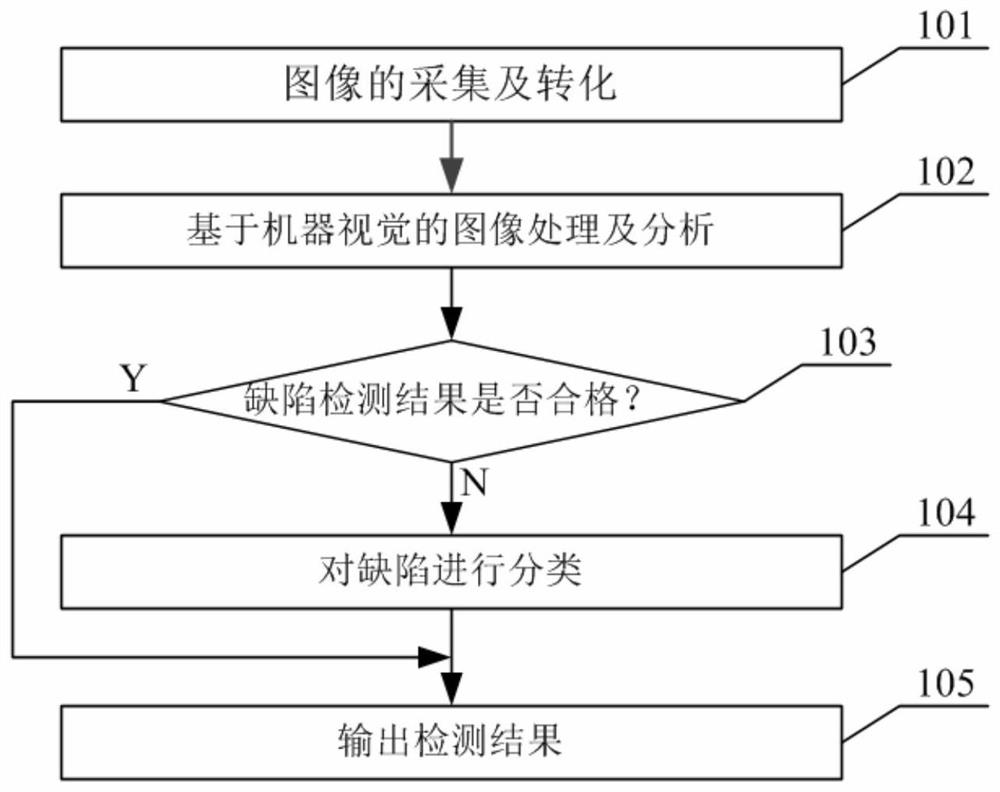

[0059] figure 1 based on figure 1 For the flow chart of the static detection method for transparent flexible packaging bags based on machine vision according to the present invention, the following will refer to figure 1 , to describe in detail the flow chart of the machine vision-based static detection method for transparent flexible packaging bags of the present invention.

[0060] First, in step 101, image acquisition and transformation.

[0061] In the embodiment of the present invention, the image is captured, and the image collected by the camera is converted into image data recognizable by the computer, and transmitted to the image processing and analysis unit.

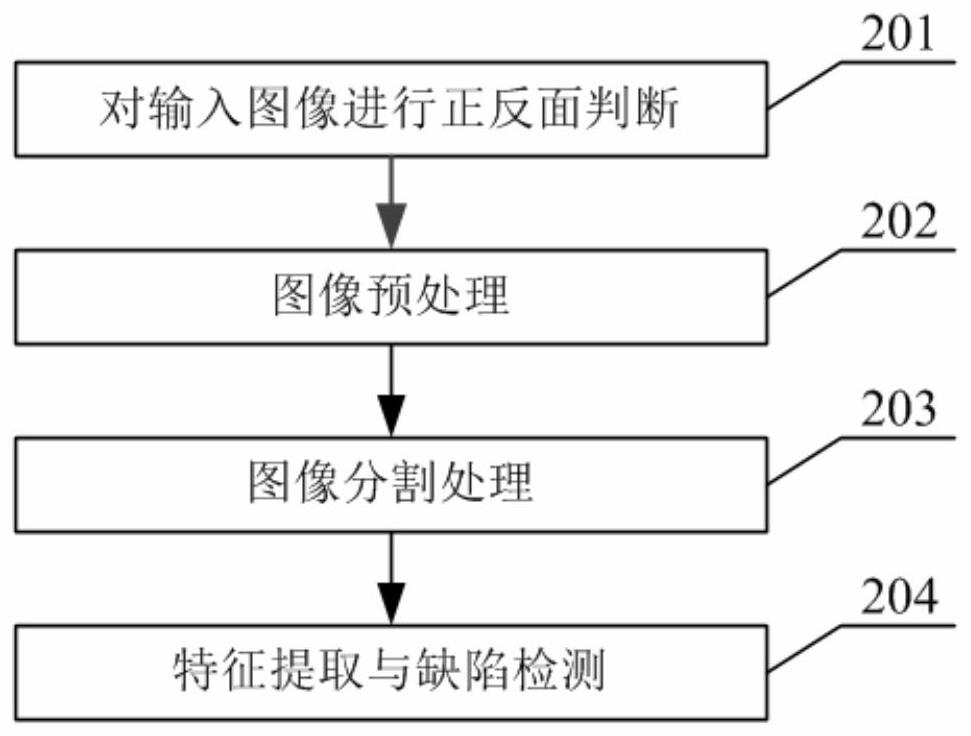

[0062] In step 102, image processing and analysis based on machine vision.

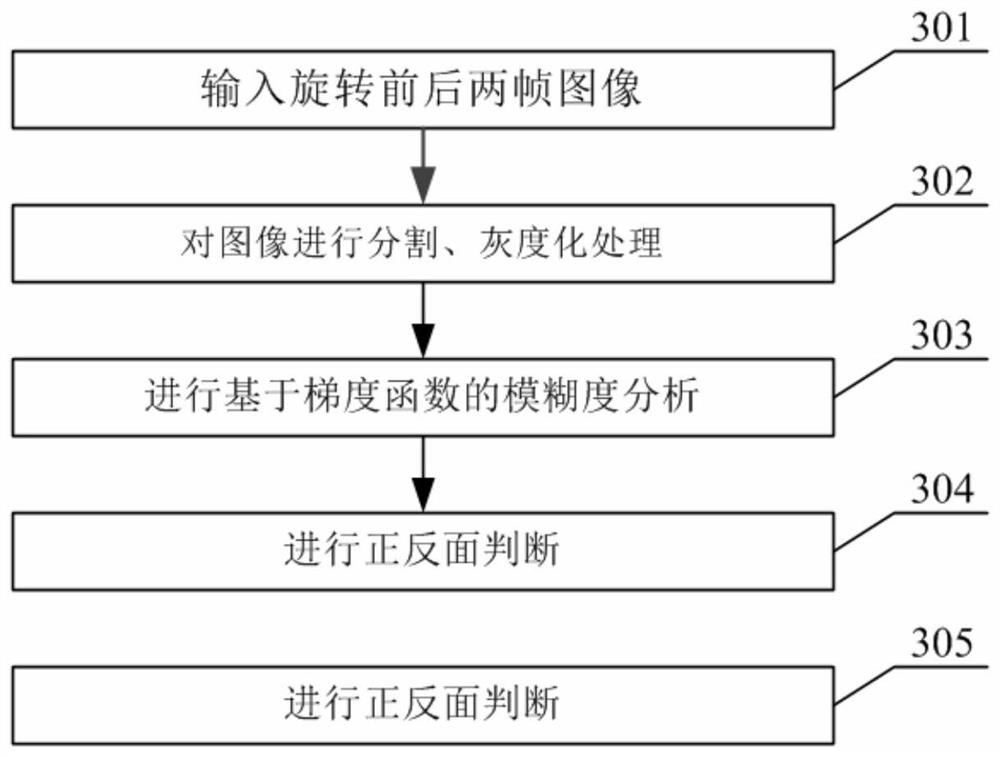

[0063] In the embodiment of the present invention, image processing based on machine vision is performed on the input image data, including front and back side judgment, image preprocessing, segmentation processing, feature extraction...

Embodiment 2

[0133] The present invention also provides a static detection system for transparent flexible packaging bags based on machine vision, Figure 6 It is a schematic structural diagram of a static inspection system for transparent flexible packaging bags based on machine vision according to the present invention, such as Figure 6 As shown, the static inspection system for transparent flexible packaging bags based on machine vision of the present invention includes an image capture unit 61, an image processing and analysis unit 62, a defect detection and judgment unit 63, and a result output unit 64, wherein,

[0134] The image capturing unit 61 is responsible for capturing images, converting the captured images into computer-recognizable image data, and sending them to the image processing and analyzing unit 62 .

[0135] The image processing and analysis unit 62 performs image processing and analysis based on machine vision on the image sent by the image capture unit 61 , and se...

Embodiment 3

[0146] In one embodiment of the present invention, there is also provided a computer-readable storage medium, on which a computer program is stored, and when the computer program is running, it executes the method for static detection of transparent flexible packaging bags based on machine vision as described above. step.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com