Square hotpot condiment capable of improving pungency and brightening and preparation process of square hotpot condiment

A hot pot bottom material, square technology, applied in the field of square hot pot bottom material and its preparation technology, can solve the problems of insufficient spiciness of hot pot bottom material, low utilization rate of spicy taste, etc., to improve the utilization rate of spicy taste, protect eyesight, and have beautiful colors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0040] Preparation Example 1: This preparation example is prepared by the following method:

[0041] (1) Take 5kg of dried peppers, 40kg of extraction agent, and 30kg of extraction agent, and set aside;

[0042] (2) Grind the dried chili powder into powder so that the dried chili powder can pass through a 50-mesh sieve, put the sieved dried chili powder into an edible ethanol extraction agent with a mass fraction of 90%, and let it stand at room temperature for 45 hours. get the leaching solution;

[0043] (3) Put the leaching solution into a distillation device, carry out distillation at a temperature of 90°C, and distill out the ethanol in the leaching solution to obtain a concentrated solution;

[0044] (4) After filtering the concentrated solution, take the filtrate and ethyl acetate extractant and mix and stir at a speed of 80r / min for 5min to obtain the extract;

[0045] (5) Put the extract into a clean distillation device and carry out distillation at a temperature of...

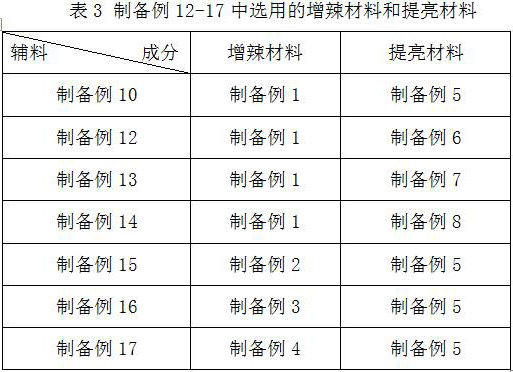

preparation example 2

[0046] Preparation Example 2: This preparation example is prepared by the following method:

[0047] (1) Take 10kg of dried peppers, 50kg of extractant, and 40kg of extractant for later use;

[0048] (2) Grind the dried chili powder into powder so that the dried chili powder can pass through a 50-mesh sieve, put the sieved dried chili powder into an edible ethanol extraction agent with a mass fraction of 90%, and let it stand at room temperature for 45 hours. get the leaching solution;

[0049] (3) Put the leaching solution into a distillation device, carry out distillation at a temperature of 90°C, and distill out the ethanol in the leaching solution to obtain a concentrated solution;

[0050](4) After filtering the concentrated solution, take the filtrate and ethyl acetate extractant and mix and stir at a speed of 80r / min for 5min to obtain the extract;

[0051] (5) Put the extract into a clean distillation device and carry out distillation at a temperature of 85°C to dist...

preparation example 3

[0052] Preparation Example 3: This preparation example is prepared by the following method:

[0053] (1) Take 15kg of dried peppers, 60kg of leaching agent, and 50kg of extraction agent, and set aside;

[0054] (2) Grind the dried chili powder into powder so that the dried chili powder can pass through a 50-mesh sieve, put the sieved dried chili powder into an edible ethanol extraction agent with a mass fraction of 90%, and let it stand at room temperature for 45 hours. get the leaching solution;

[0055] (3) Put the leaching solution into a distillation device, carry out distillation at a temperature of 90°C, and distill out the ethanol in the leaching solution to obtain a concentrated solution;

[0056] (4) After filtering the concentrated solution, take the filtrate and ethyl acetate extractant and mix and stir at a speed of 80r / min for 5min to obtain the extract;

[0057] (5) Put the extract into a clean distillation device and carry out distillation at a temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com