Equipment and method for realizing hydrothermal polymerization chemical reaction

A chemical reaction and equipment technology, applied in the field of hydrothermal polymerization chemical reaction, can solve the problems of equipment corrosion, unsuitability, waste water discharge, etc., to achieve the effect of maintaining dryness and reducing the chance of polluting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0090] During the preparation process of the deacidifying agent, the applicant found that the deacidifying agent produced under different temperatures and different grinding conditions is more effective, so the original design of the mixing drum can provide different grinding conditions and different temperatures.

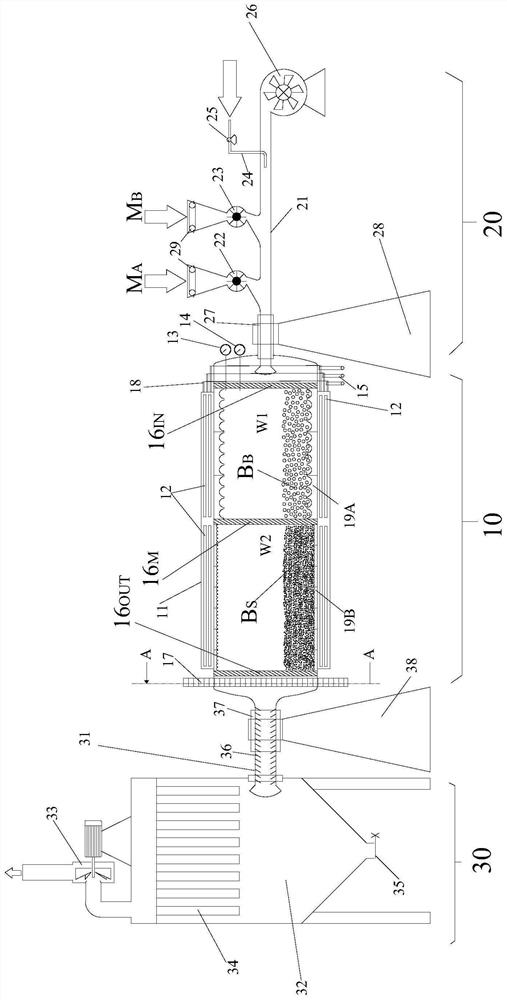

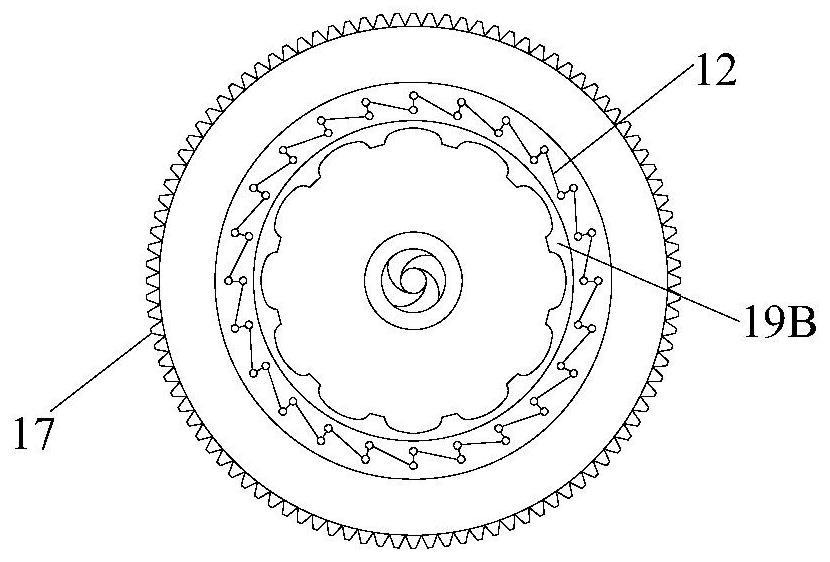

[0091] Please refer to figure 1 , one-way isolation mechanism in the middle section 16 M It is installed in the inner space of the double-layer cylinder, which divides the inner space into two relatively independent working spaces along the material conveying direction: the first working space W1 on the feeding side and the second working space W2 on the discharging side . Among them, the first group of grinding balls B in the first working space W1 B Compared with the second group of grinding balls B in the second working space W2 S The diameter of the grinding machine should be large, so that different grinding conditions can be provided in the two spaces. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com