Toughness wire tight square winding machine, tight winding square binding machine and method for tight winding square binding and binding of toughness wire

A winding machine, compact technology, applied in the direction of bundling objects, bundling materials, packaging/bundling articles, etc., can solve the problems of uneven winding, easy generation of waste, unequal number of straw ropes, etc., to achieve neat and convenient winding Packaging and Shipping, Adaptable Effects Rich

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

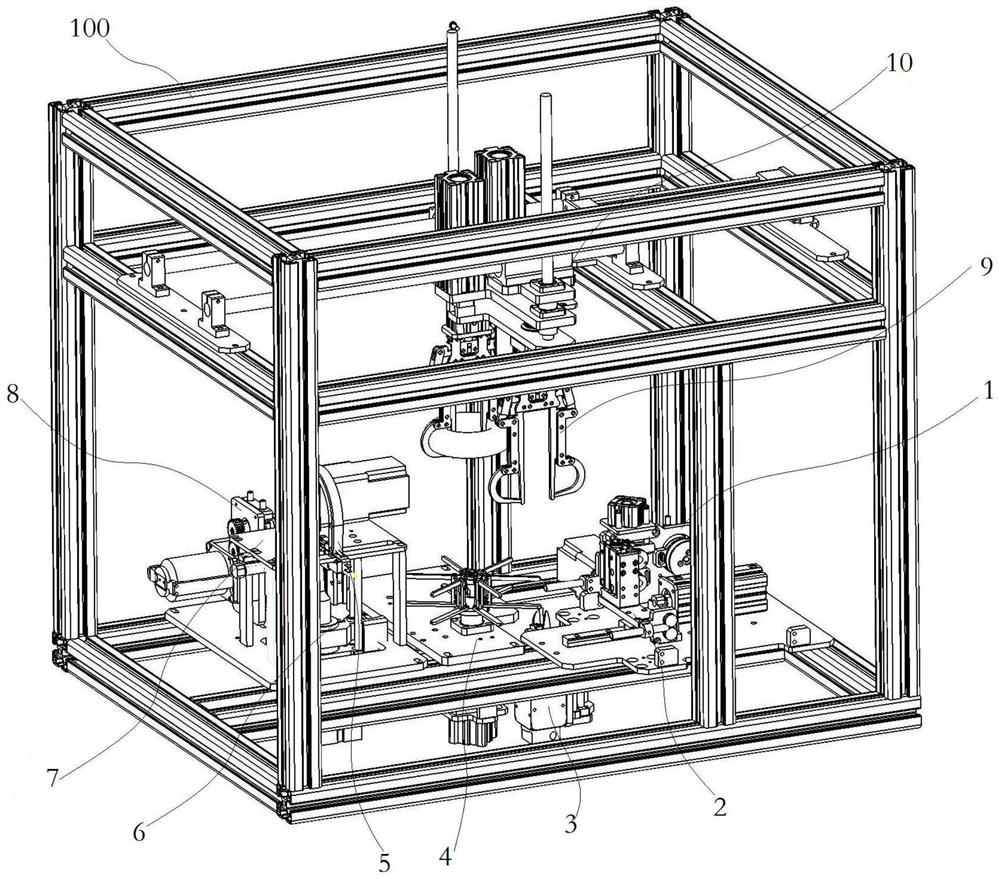

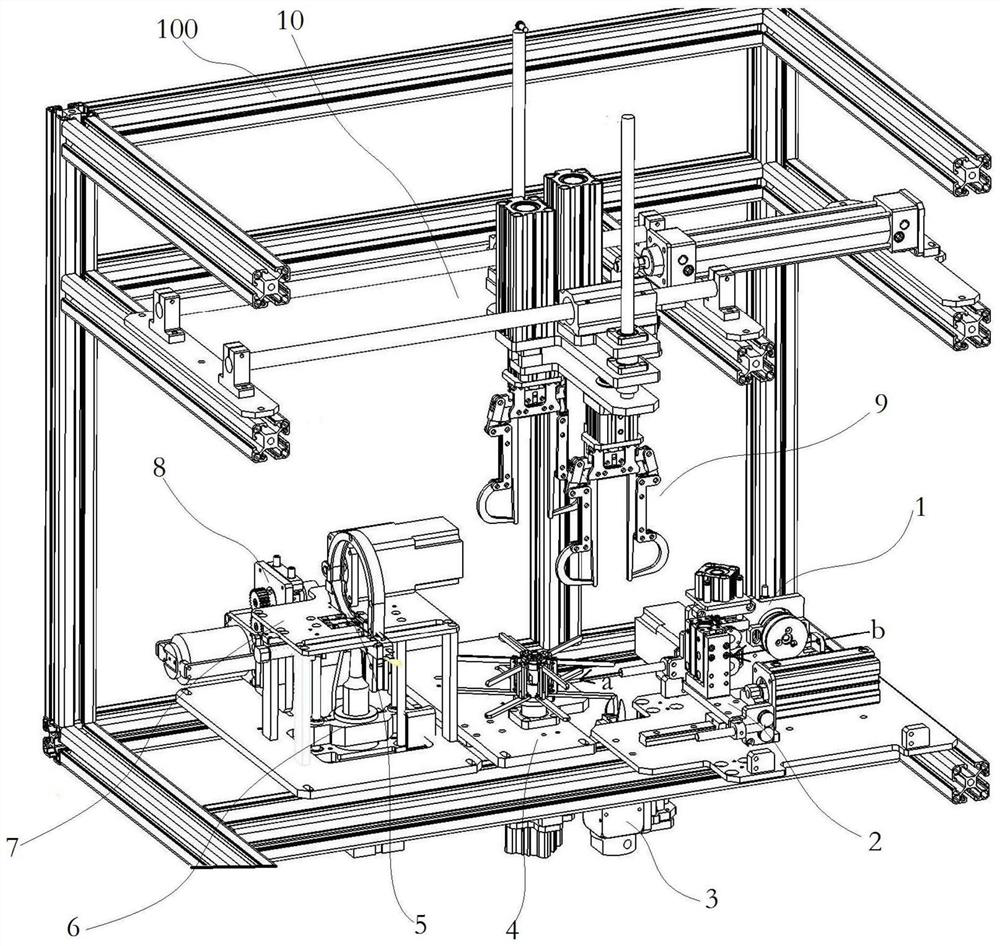

[0040] In order to facilitate the understanding of the technical solution of the present invention, the following describes in detail in conjunction with the accompanying drawings and specific embodiments.

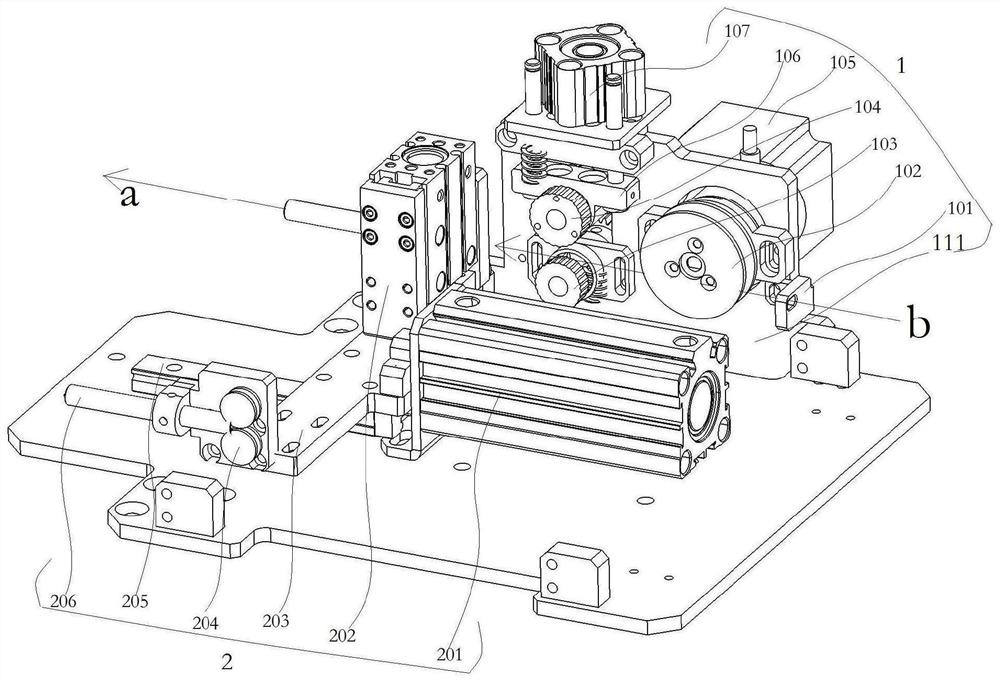

[0041] see figure 1 and 2 , in this embodiment, the flexible wire tightly squared winding machine includes a machine platform 100, the machine platform 100 is provided with a winding device 4, and also includes a straightening wire feeding device 1 and a thread end insertion device 2 And the cutting device 3, the external reeling and trimming rope is straightened and combed by the straightening and feeding device 1 and then transported forward, and the straightened trimming rope is inserted into the thread end insertion and guiding device 2 and guided by the thread end inserted into the winding device 4;

[0042] Both the straightening and feeding device 1 and the thread end insertion device 2 have a moving pair, and the two moving pairs correspond to the first vector a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com