Corrosion-resistant anti-seismic anti-cracking reinforcing mesh

A steel mesh, corrosion-resistant technology, applied in the direction of construction, building reinforcements, building components, etc., can solve the problems of easy corrosion, easy corrosion, time-consuming, etc., to improve the ability of corrosion resistance, high connection strength, The effect of strong connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

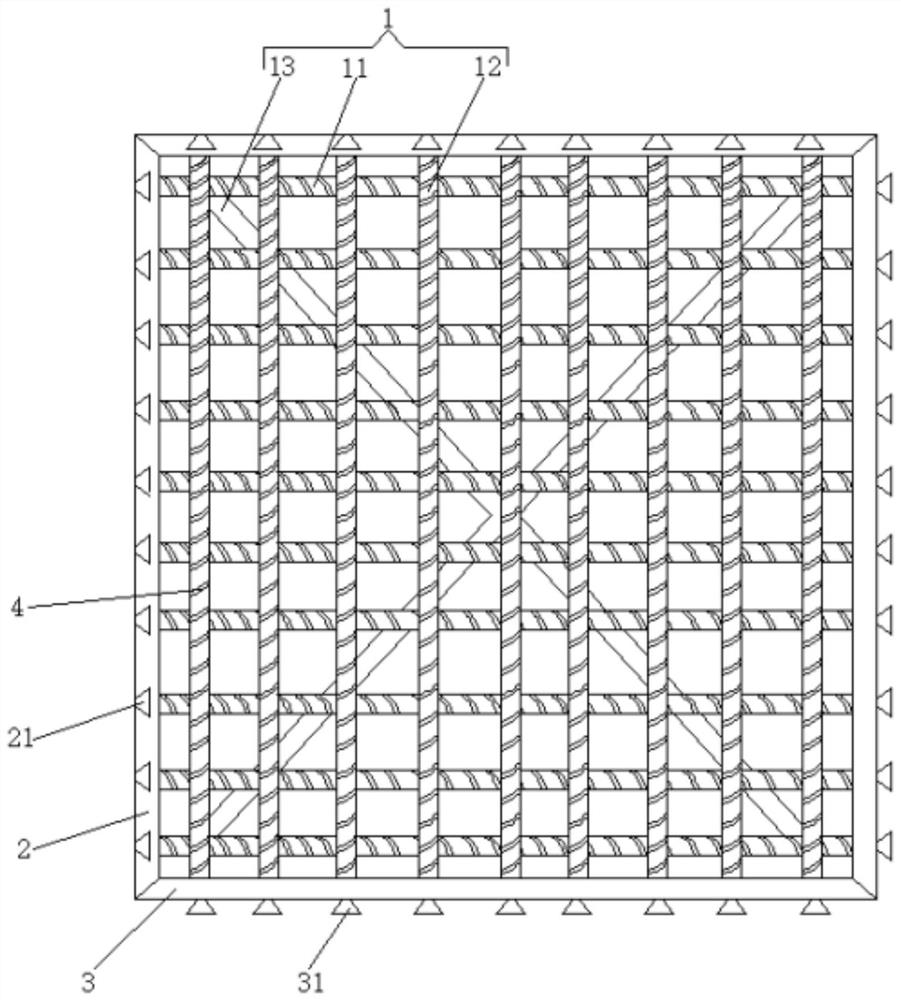

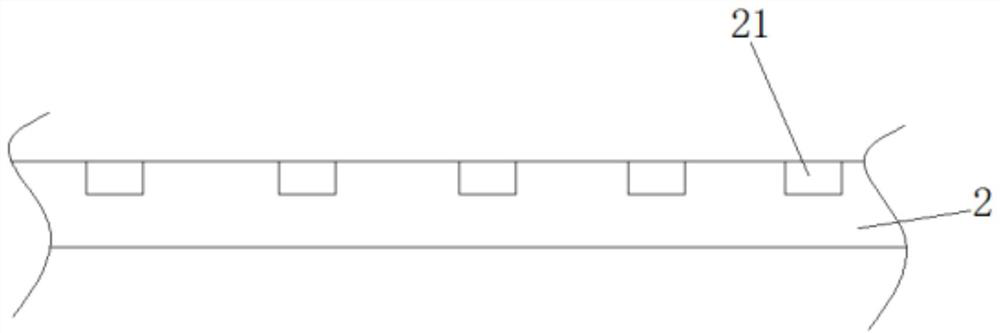

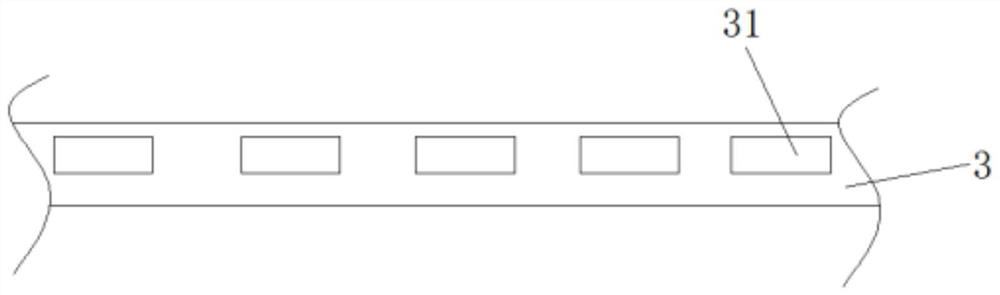

[0027] see figure 1 , 2 And 3, the present invention provides a kind of technical scheme: a kind of anti-corrosion anti-seismic anti-crack steel mesh technical scheme, comprises steel mesh sheet 1, and steel mesh sheet 1 is made up of several transversely arranged transverse bars 11 and several longitudinal bars 11 crossed and welded. Arranged vertical bars 12, the left side and the top of the steel mesh 1 are fixedly installed with the first connecting bars 2, the right side and the bottom of the steel mesh 1 are fixedly installed with the second connecting bars 3, the two first connecting bars One side of the rib 2 is equidistantly provided with several mortises 21, and one side of the two second connecting ribs 3 is equidistantly provided with several tenons 31, thereby facilitating the connection between the steel mesh 1 and the steel mesh 1, The installation speed of the steel mesh sheet 1 is accelerated, and the loss of time and manpower is also saved.

Embodiment 2

[0029] see figure 1 , 4 And 5, the present invention provides a kind of technical scheme: a kind of anti-corrosion anti-seismic anti-crack steel mesh technical scheme, comprises steel mesh sheet 1, and steel mesh sheet 1 is made up of several transversely arranged transverse bars 11 and several longitudinal bars 11 crossed and welded. Arranged vertical bars 12, the left side and the top of the steel mesh 1 are fixed with the first connecting bars 2, the right side and the bottom of the steel mesh 1 are fixed with the second connecting bars 3, the steel mesh 1 There are two obliquely staggered reinforcing ribs 13, the outer surfaces of the horizontal ribs 11 and the vertical ribs 12 are provided with threaded grooves 4, the depth and width of the threaded grooves 4 are both 1mm-1.4mm, the horizontal ribs 11 and the vertical ribs 12 The outer surface of the outer surface is coated with an anti-corrosion coating 5, the thickness of the anti-corrosion coating 5 is 2mm-3mm, the jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com